Email: [email protected] Phone: (+86) 134 1323 8643

I. Introduction

A. The Concept and Applications of XYZ Touch Probes

XYZ touch probes are innovative devices that have revolutionized the manufacturing industry. They are used to measure the position and dimensions of objects with high precision, making them ideal for a wide range of manufacturing applications.

B. Objectives of the Article

This article aims to provide a comprehensive understanding of XYZ touch probes, covering the following key aspects:

- The working principle of XYZ touch probes and their role in the manufacturing process.

- The manufacturing technology behind XYZ touch probes, including the role of manufacturers and the production process.

- The diverse applications of XYZ touch probes in manufacturing, focusing on productivity, quality control, and versatility.

- The critical role of manufacturers and factories in the selection, integration, and utilization of XYZ touch probes.

- Future trends in XYZ touch probe technology and its implications for manufacturing.

C. Manufacturers and Factories in Relation to XYZ Touch Probes

Manufacturers play a crucial role in the development and production of touch probes, ensuring their accuracy, reliability, and durability. They also provide technical support and guidance to factories that integrate these probes into their manufacturing processes.

Factories, on the other hand, are the end-users of touch probes. They leverage the capabilities of these probes to enhance their manufacturing operations, achieving higher levels of precision, efficiency, and quality control.

II. How XYZ Touch Probes Work

A. What is an XYZ Touch Probe?

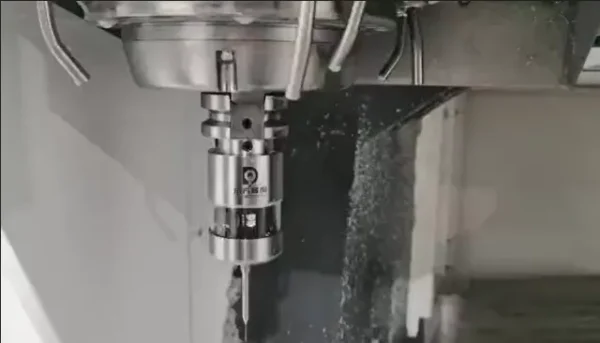

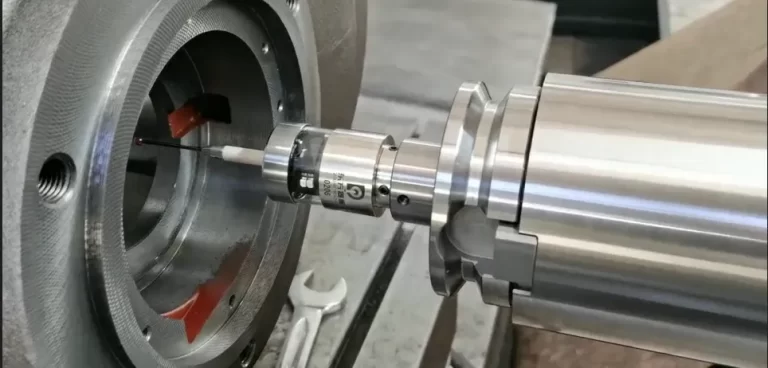

A CNC touch probe is a sensor that measures the three-dimensional coordinates of a point on an object’s surface. It consists of a stylus that makes contact with the object’s surface and a transmitter that sends a signal to a receiver. The receiver then calculates the coordinates of the point based on the time it takes for the signal to travel from the transmitter to the receiver.

B. Understanding the Working Principle

The working principle of an CNC touch probe can be summarized as follows:

- The stylus of the probe is brought into contact with the surface of the object to be measured.

- The transmitter in the probe sends a signal to the receiver.

- The receiver calculates the coordinates of the point based on the time of flight of the signal.

- The coordinates are then used to determine the position and dimensions of the object.

C. The Key Role of XYZ Touch Probes in Manufacturing

Touch probes play a critical role in various manufacturing processes, including:

- Inspection: CNC touch probes are used to inspect the dimensions and features of manufactured parts to ensure that they meet the required specifications.

- Measurement: CNC touch probes are used to measure the dimensions of objects with high precision, which is essential for quality control and process optimization.

- Reverse engineering: CNC touch probes can be used to create digital models of physical objects, which can be used for a variety of purposes, such as design, simulation, and manufacturing.

III. Manufacturing Technology of CNC XYZ Touch Probes

A. The Role and Impact of Manufacturers

Manufacturers play a vital role in the development and production of CNC touch probes. They are responsible for designing, engineering, and manufacturing these probes to meet the specific needs of their customers. The quality and reliability of CNC touch probes depend largely on the expertise and experience of the manufacturers.

B. The Production Process of CNC Touch Probes in Factories

The production process of CNC touch probes typically involves the following steps:

- Design and engineering: The manufacturer designs and engineers the probe based on the customer’s requirements.

- Manufacturing: The probe is manufactured using a variety of processes, such as CNC machining, 3D printing, and injection molding.

- Assembly: The probe is assembled and tested to ensure that it meets the required specifications.

- Calibration: The probe is calibrated to ensure that it provides accurate measurements.

C. Technological Innovations and Developments in Manufacturing

The manufacturing of CNC XYZ touch probes is constantly evolving, with new technologies being developed to improve their accuracy, reliability, and performance. Some of the latest technological advancements in this field include:

- The use of advanced materials, such as carbon fiber and ceramics, to make probes lighter and more durable.

- The development of new sensors and electronics to improve the accuracy and precision of probes.

- The integration of artificial intelligence and machine learning to make probes more intelligent and adaptable.

IV. Applications of XYZ Touch Probes in Manufacturing

A. Enhancing Production Efficiency

CNC touch probes can significantly enhance production efficiency by:

- Reducing setup times: CNC touch probes can be used to quickly and accurately set up CNC machines, reducing downtime and increasing productivity.

- Automating inspection processes:CNC touch probes can be used to automate inspection processes, eliminating the need for manual inspection and reducing the risk of human error.

- Optimizing manufacturing processes: CNC touch probes can be used to collect data on the manufacturing process, which can be used to optimize the process and improve efficiency.

B. Quality Control and Precision

CNC touch probes play a vital role in quality control by ensuring that manufactured parts meet the required specifications. They can be used to:

- Inspect the dimensions and features of manufactured parts.

- Identify and measure defects in manufactured parts.

- Ensure that manufactured parts are.

C. Versatility of CNC XYZ Touch Probes in Manufacturing Processes

CNC touch probes are versatile tools that can be used in a wide range of manufacturing processes, including:

- CNC machining: CNC touch probes can be used to set up CNC machines, measure the dimensions of workpieces, and inspect finished parts.

- 3D printing: CNC touch probes can be used to calibrate 3D printers and ensure that printed parts meet the required specifications.

- Inspection: CNC touch probes can be used to inspect the dimensions and features of manufactured parts.

- Reverse engineering: CNC touch probes can be used to create digital models of physical objects.

V. The Crucial Role of Manufacturers and Factories

A. Importance of Selecting the Right Touch Probe Manufacturer

Selecting the right touch probe manufacturer is crucial for ensuring the quality, reliability, and performance of the probes. Factors to consider when selecting a manufacturer include:

- The manufacturer’s experience and expertise in the field of touch probes.

- The manufacturer’s reputation for quality and reliability.

- The manufacturer’s ability to meet the specific needs of the customer.

B. Advantages of Integrating Touch Probes in Factories

Factories can benefit significantly from integrating touch probes into their manufacturing processes. Some of the advantages of using XYZ touch probes in factories include:

- Increased productivity: touch probes can help to reduce setup times, automate inspection processes, and optimize manufacturing processes, leading to increased productivity.

- Improved quality control: touch probes can help to ensure that manufactured parts meet the required specifications, reducing the risk of defects and improving quality control.

- Increased flexibility: touch probes can be used in a wide range of manufacturing processes, making them a flexible and versatile tool for factories.

C. Case Studies of Collaboration between Manufacturers and Factories

There are many examples of successful collaboration between manufacturers and factories in the development and implementation of XYZ touch probes. Some notable case studies include:

- The collaboration between Renishaw and Boeing to develop a new XYZ touch probe for use in the aerospace industry.

- The collaboration between Hexagon Manufacturing Intelligence and Siemens to develop a new XYZ touch probe for use in the automotive industry.

- The collaboration between FARO Technologies and GE Aviation to develop a new XYZ touch probe for use in the aviation industry.

VI. Future Trends of XYZ Touch Probes

A. Technological Innovation Directions

The technology of XYZ touch probes is constantly evolving, with new innovations being developed to improve their accuracy, reliability, and performance. Some of the key areas of technological innovation in XYZ touch probes include:

- The development of new sensors and electronics to improve the accuracy and precision of probes.

- The integration of artificial intelligence and machine learning to make probes more intelligent and adaptable.

- The development of new materials and manufacturing processes to make probes more durable and cost-effective.

B. Prospects of XYZ Touch Probes in Future Manufacturing

XYZ touch probes are expected to play an even greater role in future manufacturing. The increasing demand for precision, quality, and efficiency in manufacturing will drive the adoption of XYZ touch probes in a wide range of industries.

C. Adapting to Future Developments for Manufacturers and Factories

To stay competitive in the future, manufacturers and factories will need to adapt to the latest developments in XYZ touch probe technology. This includes investing in new equipment, training employees, and developing new manufacturing processes that leverage the capabilities of XYZ touch probes.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.