Email: [email protected] Phone: (+86) 134 1323 8643

The backbone of modern industry, machine tools are more than just metalworking marvels. These sophisticated machines are the engineers of our world, shaping raw materials into the intricate components that power our everyday lives. From the cars we drive to the smartphones we hold, the influence of machine tools is undeniable. This article delves into the fascinating world of machine tools, exploring their fundamental role, historical evolution, cutting-edge advancements, and the role they play in shaping the future of manufacturing.

Exploring the Fundamental Role of Machine Tools in Modern Industry

Machine tools are the workhorses of the manufacturing industry. They are power-driven machines designed to handle and shape rigid materials, primarily metals, through various processes like cutting, shearing, boring, and grinding. These precise and efficient machines are crucial for creating a vast array of components, from simple nuts and bolts to complex engine parts and aerospace components. Their ability to achieve high levels of accuracy and repeatability ensures consistent product quality and facilitates mass production, a cornerstone of modern industry.

Understanding Machine Tools

1. What is Machine Tools: A Comprehensive Definition

In essence, a machine tool is a machine that utilizes a cutting tool or other tooling to manipulate a workpiece (the material being shaped). These machines hold and control the cutting tool and the workpiece, precisely moving them relative to each other to achieve the desired shape and dimensions. The control system can be manual, where an operator directly influences the machine’s movements, or computer-controlled, using advanced technologies like Computer Numerical Control (CNC) for precise and automated operation.

2. Delving into the Essential Functions and Types of Machine Tools

Machine tools perform a variety of functions critical to manufacturing. Some of the most essential functions include:

- Cutting:Removing excess material from a workpiece to achieve the desired shape and size. This can be done through various processes like drilling, milling, turning, and sawing.

- Forming:Shaping a workpiece by plastic deformation, such as bending, pressing, or rolling.

- Finishing:Smoothing and refining the surface of a workpiece using processes like grinding, polishing, and lapping.

There are numerous types of tools, each designed for specific functions and materials. Some common types include:

- Lathes:Rotates the workpiece while a cutting tool removes material to create cylindrical or conical shapes.

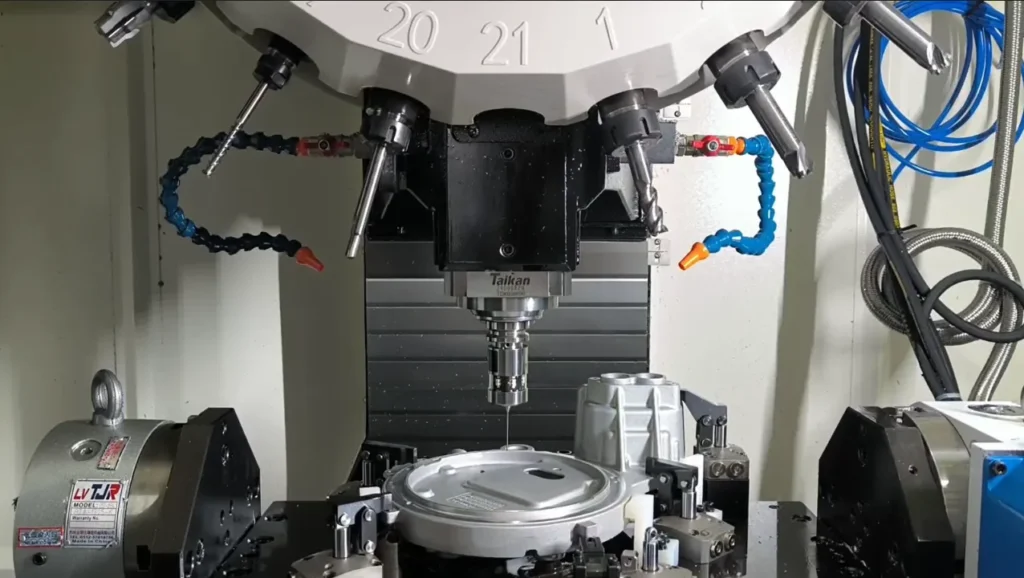

- Milling Machines:Uses multiple cutting tools to remove material from a workpiece, creating flat surfaces, slots, gears, and complex contours.

- Drilling Machines:Creates holes in workpieces using rotating drill bits.

- Grinders:Uses an abrasive wheel to smooth and refine the surface of a workpiece.

- Saws:Employ a band or circular saw blade to cut workpieces into desired shapes.

Evolution of Machine Tools

1.Enhancing Precision and Efficiency

The history of tools is a testament to human ingenuity. From the early, rudimentary lathes powered by waterwheels to the sophisticated CNC machines of today, machine tools have undergone a remarkable evolution.

The Industrial Revolution marked a turning point, with the invention of machines like the steam engine providing the necessary power for larger and more powerful machine tools. This led to increased production rates and greater precision in manufacturing.

The 20th century saw the rise of automation and computerization. The development of CNC machines revolutionized the industry, allowing for highly precise and repeatable machining processes with minimal human intervention. This significantly improved productivity and enabled the creation of complex parts with previously unimaginable accuracy.

2. Examining the Crucial Role of Machine Tools in Manufacturing Processes

Tools play a central role in various stages of the manufacturing process. From raw material processing to final product assembly, these machines are instrumental in shaping components with precision and efficiency. Here are some specific examples:

- Automotive Industry:Machine tools are used to create various engine parts, transmissions, chassis components, and body panels.

- Aerospace Industry:These machines are used to manufacture complex aircraft components like wings, fuselages, and landing gear.

- Medical Device Industry:Machine tools are crucial for creating precise and sterilized surgical instruments and implants.

- Consumer Electronics:The intricate components found in smartphones, computers, and other electronic devices are often shaped using machine tools.

Innovative Technologies in Machine Tools

1.Advancements in Machine Tools: Embracing High-Tech Solutions

Modern machine tools are at the forefront of technological innovation. Here are some key advancements shaping the future of this industry:

- CNC Machining:CNC technology allows for precise and automated control of machine movements based on computer-generated programs. This ensures consistent product quality and facilitates complex machining processes.

- Additive Manufacturing (3D Printing):This emerging technology allows for the creation of 3D objects by layering material. While not a replacement for traditional machine tools, 3D printing offers unique capabilities for creating complex geometries and prototypes.

- Robotics and Automation:Industrial robots are increasingly integrated with machine tools, enabling automated material handling, loading, and unloading of workpieces. This improves efficiency and reduces the need for human intervention in potentially hazardous tasks.

- Artificial Intelligence (AI):AI has the potential to revolutionize machine tool operation by enabling:

- Predictive Maintenance:AI can analyze sensor data from machines to predict potential failures and schedule maintenance before breakdowns occur.

- Process Optimization:AI algorithms can analyze machining processes and recommend adjustments to optimize cutting parameters, leading to improved efficiency and reduced production costs.

- Self-Learning Machines:In the future, machine tools equipped with AI might be able to learn and adapt to different machining scenarios, further enhancing their capabilities.

2. Exploring the Latest Innovations and Future Trends in Machine Tool Technology

The future of machine tools is bright, with continuous advancements in technology pushing the boundaries of what’s possible. Here are some exciting trends to watch:

- Sustainable Manufacturing:The development of eco-friendly coolants, lubricants, and machining processes will be crucial for minimizing the environmental impact of machine tool operation.

- Advanced Materials:As new materials with unique properties are developed, machine tools will need to adapt to handle these materials efficiently.

- Cybersecurity:With increasing automation and connectivity, cybersecurity will be paramount to protect machine tools from cyberattacks that could disrupt production.

How to Choose the Right Machine Tool for Your Needs?

Choosing the right machine tool is just like picking the right car for your needs – a wrong choice can be costly. Here’s a breakdown to help you make an informed decision:

Understanding your Needs:

- Current & Future Needs:Consider what you’re machining now and what you might be making in the future. The machine should be adaptable for growth.

- Production Volume:Are you doing small one-off projects or high-volume production runs? This will influence the machine’s capacity and automation needs.

- Material:The type of material you’ll be working with (wood, metal, plastic) will influence the power and features required by the machine tool.

- Part Complexity:Simpler parts might be suitable for manual machines, while intricate designs may necessitate CNC (Computer Numerical Control) machines.

- Industry Standards:Different industries (aerospace, medical) have varying tolerance and precision requirements. Pick a machine that meets those standards.

Do your Research:

- Features to Consider:Spindle speed, horsepower, tool capacity, and working area are all crucial factors depending on your needs.

- Manual vs. CNC:For high-precision and repetitive tasks, CNC offers greater accuracy and repeatability. Manual machines provide more flexibility for one-off projects.

- New vs. Used:Consider your budget and warranty needs. Newer machines offer better technology but come at a premium. Used machines can be a good option if inspected thoroughly.

Beyond the Basics:

- Machine Footprint:Think about the space you have available to accommodate the machine.

- Training and Support:Ensure you or your staff have the skills to operate the machine. Good after-sales support is also important.

Don’t get carried away by fancy features. Focus on finding a machine that meets your specific needs and budget. By carefully considering these factors, you’ll be well on your way to selecting the perfect machine tool for your workshop.

Common Questions about Machine Tools

1. What are the primary functions of machine tools?

Machine tools perform a variety of functions essential to manufacturing, including:

- Cutting: Removing excess material to achieve the desired shape and size.

- Forming: Shaping a workpiece by plastic deformation (bending, pressing, rolling).

- Finishing: Smoothing and refining the surface of a workpiece (grinding, polishing, lapping).

2. How do machine tools contribute to manufacturing efficiency?

Machine tools contribute to manufacturing efficiency in several ways:

- Automation:CNC technology and robotics allow for automated operation, minimizing human intervention and reducing production time.

- Precision and Repeatability:Machine tools can achieve high levels of accuracy and repeatability, ensuring consistent product quality and reducing waste.

- High Production Rates:Modern machine tools are capable of operating at high speeds, leading to increased production output.

3. What are the different types of machine tools available?

There are numerous types of machine tools, each suited for specific functions and materials. Some common types include:

- Lathes

- Milling Machines

- Drilling Machines

- Grinders

- Saws

4. What role do machine tools play in industrial automation?

Machine tools are a cornerstone of industrial automation. Their ability to be computer-controlled and integrated with robots allows for automated production lines, significantly improving efficiency and reducing reliance on manual labor.

Conclusion

Machine tools are the unsung heroes of modern industry. From shaping the building blocks of our infrastructure to crafting the intricate components of our technological marvels, these powerful machines play a vital role in our everyday lives. As technology continues to evolve, machine tools will undoubtedly become even more sophisticated and adaptable, shaping the future of manufacturing and driving innovation across various industries.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.