Email: [email protected] Phone: (+86) 134 1323 8643

What does the tool setter benifit your manufacturing?

What Does a Tool Setter Do?

Many people ask “What does a tool setter do?” A tool setter is a skilled machinist responsible for the setup and operation of CNC machine tools. They ensure that the machines are properly configured and that the tools are set to the correct height and position. This is a critical role in the manufacturing process, as it ensures that the parts produced are accurate and meet the required specifications. Their job duties include:

- Inspecting workpieces for defects

- Measuring workpieces to determine accuracy of machine operation

- Taking measurements of reference points for setting the machine

- Making adjustments to the machine tool

Performing periodic quality checks on the products made by the machines

The Role of Tool Height Sensors and CNC Tool Height Probes

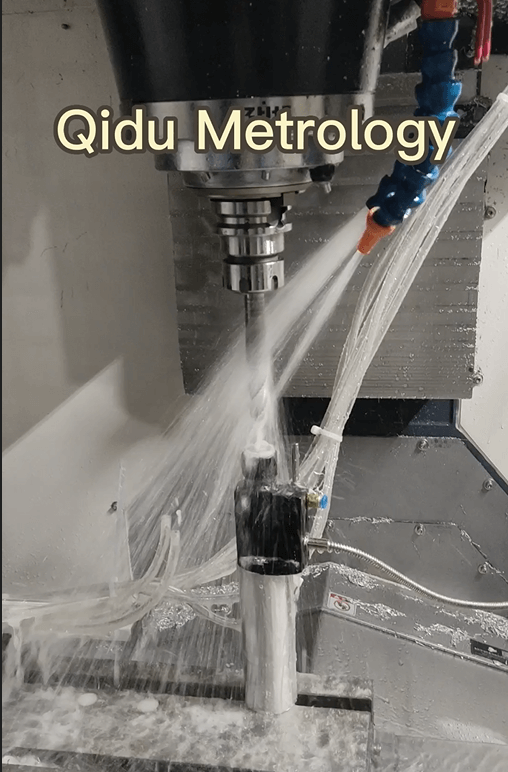

One of the most important tools used by a tool setter is a tool height sensor. This device is used to measure the height of the tool relative to the workpiece. This information is then used to offset the machine’s coordinates so that the tool cuts the workpiece at the correct depth.

Another important tool used by tool setters is a CNC tool height probe. This device is used to measure the length and diameter of the tool. This information is then used to program the machine so that it can use the tool correctly.

The Importance of Tool Setting

What does a tool setter do? Tool setting is a critical part of the manufacturing process. It ensures that the parts produced are accurate and meet the required specifications. If the tools are not set correctly, it can lead to a number of problems, including:

Scrap parts: Parts that are not cut to the correct dimensions or that have дефекты will need to be scrapped. This can lead to significant financial losses.

Tool damage: If the tools are not set correctly, they can be damaged. This can lead to downtime and additional costs.

Safety hazards: Incorrectly set tools can create safety hazards for the machine operator.

The Skills of a Tool Setter

What does a tool setter do? A tool setter is highly skilled machinists who have a deep understanding of CNC machine tools and the tools used with them. They are also proficient in the use of tool height sensors and CNC tool height probes.

In addition to their technical skills, tool setters must also have strong problem-solving skills. They must be able to identify and correct problems with the machine tools or the tools themselves.

The Future of Tool Setting

The field of tool setting is constantly evolving. New technologies are being developed that make it easier and more accurate to set tools. For example, some CNC machine tools now have built-in tool height sensors. This eliminates the need for a separate tool height sensor and makes it easier to set the tools.

As technology continues to evolve, the role of the tool setter will continue to change. However, the need for skilled tool setters will remain. These machinists play a critical role in the manufacturing process, and their skills will continue to be in high demand.