Email: [email protected] Phone: (+86) 134 1323 8643

Unveiling Precision and Productivity with Lathe Touch Probe

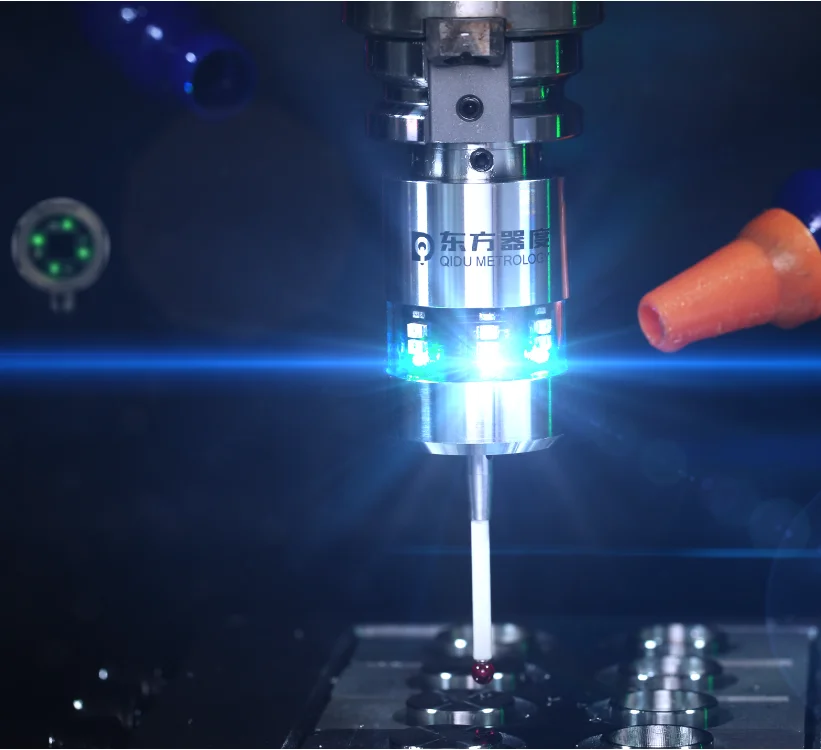

Revolutionizing CNC Machining with Advanced Machine Tool Probes

In the ever-evolving landscape of CNC machining, the role of cutting-edge technologies becomes increasingly crucial. Among the transformative tools that have taken center stage is the Lathe Touch Probe—a game-changer in the realm of precision manufacturing. This article explores the multifaceted advantages of Lathe Touch Probes, delving into their impact on productivity, the significance of machine tool probes, and the nuanced world of measuring probes for CNC.

Precision Redefined: The Lathe Touch Probe Advantage

At the heart of precision machining lies the ability to measure and adjust with utmost accuracy. The Touch Probe emerges as a beacon of precision, allowing machinists to achieve unparalleled accuracy in their operations. This advanced technology employs a combination of tactile and optical sensing, enabling the seamless measurement of workpiece dimensions. By integrating the Touch Probe into CNC lathes, manufacturers can attain sub-micron level precision, ensuring that every component meets the stringent quality standards demanded by modern industries.

The Touch Probe’s contribution to precision is not limited to measurements alone. Its real-time feedback mechanism allows for dynamic adjustments during machining processes, compensating for tool wear and workpiece variations. This capability not only enhances the accuracy of the final product but also extends the lifespan of cutting tools, reducing operational costs and downtime.

The Role of Machine Tool Probes in CNC Machining

Machine tool probes have become indispensable in CNC machining, serving as the eyes and hands of the manufacturing process. In this context, the Touch Probe stands out as a key player, offering a comprehensive solution for both measurement and in-process control. These probes play a pivotal role in automating the inspection process, ensuring that each workpiece conforms to the predetermined specifications.

One notable application of machine tool probes is in the alignment of workpieces. The Lathe Touch Probe’s ability to precisely locate and align the workpiece streamlines the setup process, reducing the time required for manual adjustments. This not only accelerates production cycles but also minimizes human errors, elevating overall efficiency in CNC machining operations.

Navigating the Complexities: Measuring Probe for CNC Unveiled

Within the CNC machining sphere, the need for accurate measurement is paramount. Enter the measuring probe for CNC, a specialized tool designed to provide meticulous data on workpiece dimensions. The Touch Probe, as a measuring probe for CNC, brings a new level of sophistication to this critical aspect of machining.

This measuring probe integrates seamlessly with CNC systems, facilitating automatic measurement routines. Machinists can program the Touch Probe to conduct precise measurements at specific intervals, ensuring continuous monitoring of the machining process. The result is a comprehensive dataset that not only validates the quality of each component but also contributes to the optimization of machining parameters for future runs.

Synergy in Action: Integrating Touch Probes for Maximum Impact

To fully harness the benefits of Touch Probes, a holistic approach to integration is essential. Manufacturers must consider factors such as machine compatibility, programming requirements, and operator training. When implemented effectively, the synergy between Touch Probes and CNC machinery creates a harmonious production environment where precision and productivity coalesce.

The programming aspect of Touch Probes involves defining measurement routines and in-process control parameters. Machinists can tailor these routines to the specific requirements of each job, ensuring a customized approach that aligns with the intricacies of diverse manufacturing processes.

Conclusion: A New Era of Precision Manufacturing

In conclusion, the Touch Probe emerges as a transformative force in CNC machining, epitomizing precision and productivity. Machine tool probes, with the Touch Probe at the forefront, redefine the capabilities of modern manufacturing by automating measurements, enhancing in-process control, and optimizing overall efficiency.

As the industry continues to evolve, embracing technologies like the Lathe Touch Probe becomes imperative for those seeking a competitive edge. The measuring probe for CNC, with its meticulous data acquisition capabilities, further solidifies the Lathe Touch Probe’s role in shaping a new era of precision manufacturing. With a keen eye on innovation and a commitment to excellence, the integration of Touch Probes is poised to set new benchmarks in the ever-evolving landscape of CNC machining.