Email: [email protected] Phone: (+86) 158 8966 5308

تونۇشتۇرۇش

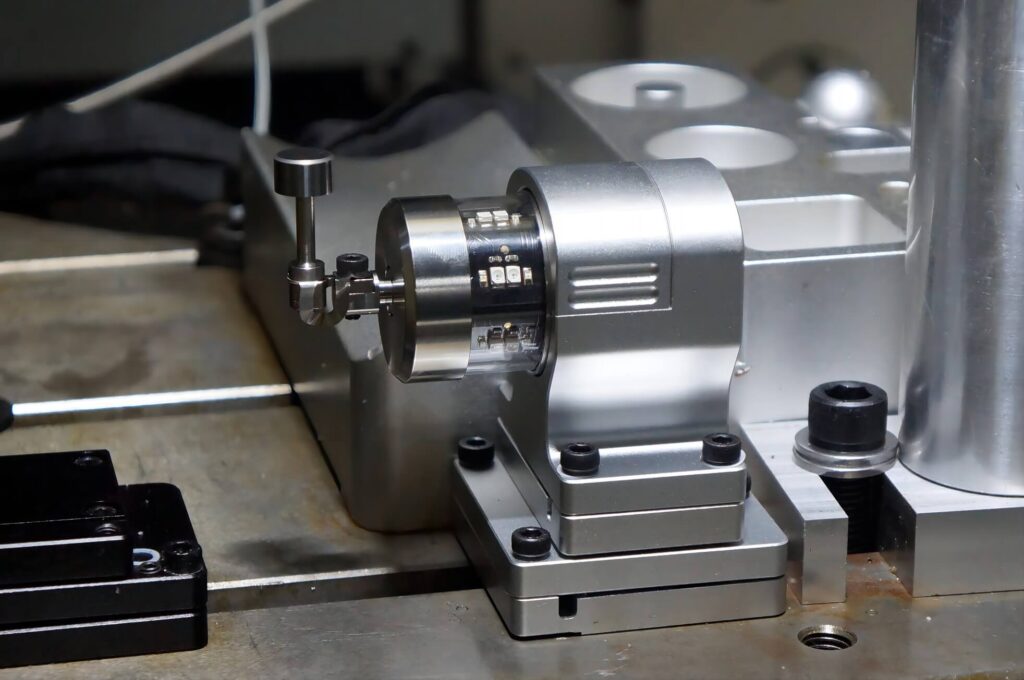

In the dynamic world of manufacturing, precision, efficiency, and cost-effectiveness are the cornerstones of success. Amidst the ever-evolving landscape of industrial technology, optical tool setters have emerged as transformative tools, revolutionizing the way workshops operate. These sophisticated devices harness the power of optics to streamline and enhance manufacturing processes, delivering a multitude of benefits that are propelling the industry forward.

Enhancing Efficiency

At the heart of optical tool setters lies their ability to optimize production workflows, leading to significant gains in efficiency. By automating and streamlining the tool setting process, these devices eliminate the need for manual adjustments, reducing downtime and ensuring a continuous flow of operations. This translates into faster cycle times, increased output, and a more responsive production environment.

Modern optical tool setters incorporate cutting-edge technologies that further amplify their efficiency-boosting capabilities. High-frequency image processing, for instance, enables real-time monitoring of tool wear and tear, allowing for proactive maintenance and preventing unexpected disruptions. Additionally, advanced algorithms optimize tool positioning and alignment, minimizing tool breakage and ensuring consistent product quality.

Elevating ئېنىقلىق

Precision is paramount in manufacturing, and tool setters play a pivotal role in achieving unparalleled accuracy. Their ability to measure and align tools with submicron precision ensures that every component is manufactured within the tightest tolerances, minimizing defects and enhancing product quality.

The technical prowess of tool setters lies in their sophisticated optical systems and advanced software algorithms. These components work in synergy to capture high-resolution images of tools, extract precise dimensional data, and calculate the optimal alignment parameters. This meticulous approach ensures that tools are positioned with the utmost accuracy, enabling the production of high-precision components that meet the most demanding specifications.

Reducing Costs

The benefits of optical tool setters extend beyond efficiency and precision, reaching into the realm of cost-effectiveness. By streamlining processes, minimizing downtime, and reducing tool breakage, these devices contribute to significant cost savings. Additionally, their ability to optimize cutting parameters and extend tool life further enhances resource conservation, leading to lower production costs.

Effective utilization of tool setters is crucial for maximizing their cost-saving potential. By integrating these devices into comprehensive production management systems, manufacturers can gain real-time insights into tool performance, identify areas for improvement, and optimize resource allocation. This data-driven approach enables proactive cost control strategies, ensuring that every dollar spent is utilized efficiently.

Future Outlook of Optical Tool Setter

Optical tool setters are not merely technological advancements; they represent a paradigm shift in workshop operations. Their transformative impact is poised to shape the future of manufacturing, driving innovation and propelling the industry towards new heights of efficiency, precision, and cost-effectiveness.

As technology continues to evolve, tool setters are expected to become even more sophisticated, incorporating artificial intelligence and machine learning capabilities. These advancements will further enhance their ability to adapt to complex manufacturing environments, optimize processes in real-time, and deliver unprecedented levels of performance.

The impact of optical tool setters extends beyond individual workshops, influencing the broader manufacturing landscape. Their ability to streamline production, enhance precision, and reduce costs is likely to drive consolidation within the industry, favoring manufacturers who embrace these technologies. Additionally, the proliferation of optical tool setters is expected to accelerate the adoption of Industry 4.0 principles, fostering a more interconnected and data-driven manufacturing ecosystem.

Frequently Asked Questions of Optical Tool Setter

1.How to choose the right optical tool setter?

The selection of an optical tool setter depends on several factors, including the specific manufacturing application, the type of machinery being used, and the desired level of precision. It is crucial to consult with experienced professionals and evaluate the features and capabilities of different models to ensure the optimal choice for individual needs.

2.What is the installation and usage process for optical tool setters in workshops?

The installation and usage process for optical tool setters typically involves mounting the device onto the machine tool, connecting it to the control system, and configuring the software parameters. Once installed, operators can utilize the tool setter to measure, align, and optimize tools with minimal manual intervention. Detailed user manuals and training resources are provided by manufacturers to ensure proper installation and operation.

3.What are the key differences between optical tool setters and traditional tool setters?

Optical tool setters offer several advantages over traditional tool setters, including:

- Higher precision:Optical version can achieve submicron precision, far surpassing the capabilities of traditional methods.

- Automated operation:Optical version automate the tool setting process, eliminating the need for manual adjustments and reducing the risk of human error.

- Real-time monitoring:Optical version provide real-time monitoring of tool wear and tear, enabling proactive maintenance and preventing unexpected downtime.

- Data-driven insights:Optical version collect and analyze data, providing valuable insights into tool performance and process optimization.

4.Are optical tool setters suitable for different types of machining tasks?

Optical tool setters are indeed suitable for a wide range of machining tasks, including:

- Milling: They can accurately measure and align cutting tools for milling operations, ensuring precise tool positioning and consistent part quality.

- Turning:They are well-suited for turning operations, enabling precise alignment of turning tools and optimizing cutting parameters for efficient material removal.

- Drilling:They can accurately measure and align drill bits, ensuring precise hole placement and consistent hole depth.

- Grinding:They are used in grinding operations to precisely align grinding wheels, achieving high-precision surface finishes.

The versatility of optical tool setters makes them a valuable asset for workshops engaged in diverse manufacturing processes.

خۇلاسە

Optical tool setters have emerged as transformative tools, revolutionizing the way workshops operate. Their ability to enhance efficiency, elevate precision, and reduce costs has made them indispensable components of modern manufacturing environments. As technology continues to advance and Industry 4.0 principles gain traction, they are poised to play an even more pivotal role in shaping the future of manufacturing, driving innovation and propelling the industry towards new heights of productivity and success.

In conclusion, optical tool setters represent a paradigm shift in workshop operations, offering a multitude of benefits that are propelling the manufacturing industry forward. Their impact is far-reaching, encompassing enhanced efficiency, unparalleled precision, and significant cost savings. As technology continues to evolve, they are poised to become even more sophisticated, further revolutionizing manufacturing processes and driving innovation across the industry landscape. Embrace the transformative power of optical tool setters and embark on a journey towards a future of manufacturing excellence.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.