Email: [email protected] Phone: (+86) 134 1323 8643

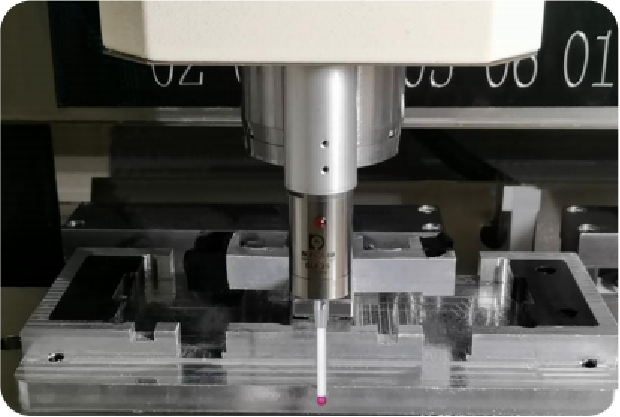

3D Touch Probe DLP25

Workpiece centering, dimensional measurement and positioning

Cable 3D Touch Probe

- High Precison

- High Stability

- Double clamping method

- IP68 protection level

Model | DLP25 | |

Repeatability(2σ) | <1um | |

Trigger direction | ±X ,±Y ,+Z | |

Trigger force | XY plane: 0.4-0.8N | Z: 4.0N |

Protective range | XY plane: +/-12.5。 | Z: 6.2mm |

Signal transmission mode | Cable | |

Trigger life | >10 million | |

Weight | 80g | |

Cable | 5m, oil resistance, 4 cores, φ5mm | |

Sealing protection level | IP 68 | |

Operating temperature | 0-60℃ | |

Features of 3D Touch Probe

Ultra-rigid Trigger Structure

Using ultra-precision micron-level assembly process. Probe comprehensive sensitivity <1um.

High Stability

Stable and reliable running process of the probe, no abnormal alarm.Micro-damping reset technology is applied.

Sealing

IP 68 sealing level, which is the highest level in the industry. Besides, we use the anti-aging imported sealing material to make sure the best quality.

Double clamping method

Two mounting methods are available for various types of machines: clamping installation method and threaded installation method.

High Flexible Cable

The high flexible cable used by the probe ensures the stability of signal transmission under the machining conditions.

Long triggering life

The structure, material selection and process design are completely designed and verified according to the trigger life standard exceeding 10 million times.

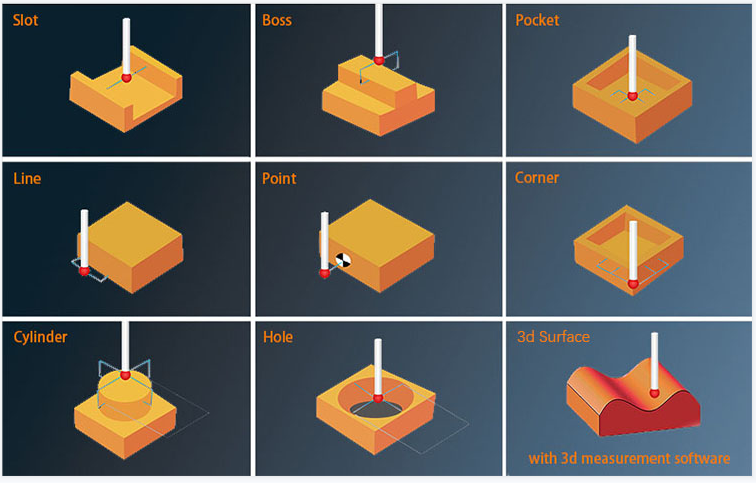

Product Application of 3D Touch Probe

Automatic Reference Finding of Workpieces

- Automatically find product benchmarks

- Automatically modify the coordinate system

Automatic Centering of Workpieces

- Automatic product centering

- Automatically modify the coordinate system

Automatic Correction of Workpieces

- Automatically find the product angle

- Automatically modify the coordinate system

Dimensional Measurement of the Workpiece after the Sequence

- Monitoring of key dimensions after product sequence

Description of 3D Touch Probe

DLP25 is a 3D touch probe designed for the on- line measurement of various CNC machines, which can conduct high-precision measurement of processing scenarios, such as workpiece set-up inspection before processing, key dimension measurement during processing and all dimension measurement after process-ing(before disassembling the workpiece).

DLP25 uses hard cable to transmit signals, which can achieve stable and reliable signal transmission in various harsh working environments of CNC machining, and avoid false triggering.

Compared with wireless probe, cable probe has higher cost performance. On the premise that the operation of the machine tool is not affected by the cable, DLP25 is preferred for on-line measurement.

DLP25 can be widely used in high gloss machine,fine engraving machine, grinding machine, NC lathe and customized automation.