Email: [email protected] Phone: (+86) 134 1323 8643

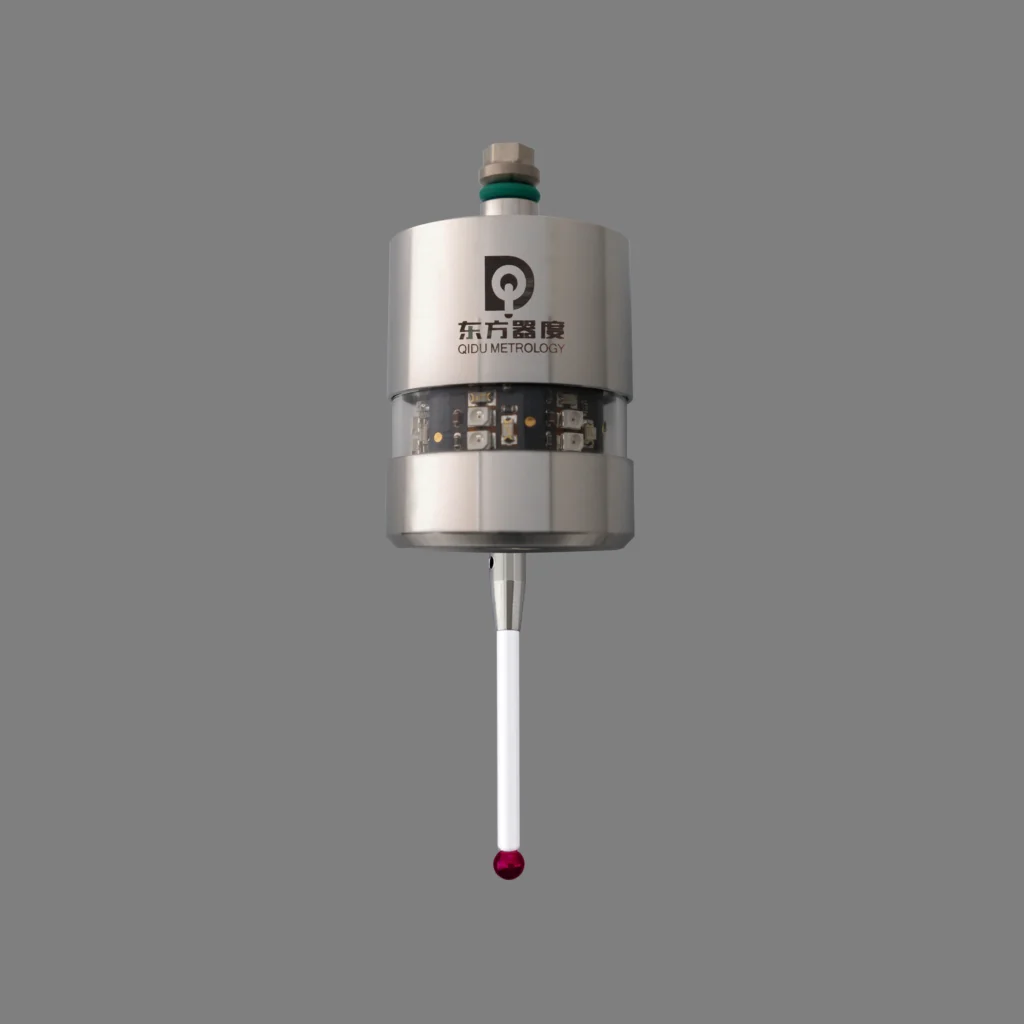

Qidu Metrology Touch Probe

Qidu Metrology’s touch probes excel in swiftly and precisely determining the base position of workpieces, automatically configuring or modifying the workpiece coordinates. These CNC probes serve as an efficient solution to enhance the precision of your workpieces and the overall productivity of your manufacturing lines.

Qidu Metrology’s touch probes not only result in substantial cost savings but also bring about quality improvements in applications across aerospace, automotive, electronics, and various other industries.

As a leading manufacturer and supplier of touch probes, Qidu Metrology ensures to provide you with the most suitable solutions tailored to your requirements. Our CNC probes guarantee premium quality and customer satisfaction. Rest assured that our CNC probe prices are reasonable.

Why Customers Choose Qidu Metrology Touch Probe

- High Precision: Accurate measurements meet clients’ exacting standards.

- Advanced Technology: Cutting-edge solutions for diverse metrology needs.

- Customization: Tailored products to match specific customer requirements precisely.

- Exceptional Support: Dedicated service ensures customer satisfaction from inquiry to post-sales.

- Competitive Pricing: Affordable options without compromising quality or performance.

- High Protection: IP68 rated for high durability and applicable on fast moving machine tools.

- Reliability: Dependable equipment ensures consistent and reliable measurement results.

- Efficiency: Streamlined processes and solutions save time and resources.

Functions of the Touch Probe

- Facilitates automated alignment and placement of workpieces within the machine tool.

- Enhances accuracy in workpiece positioning, consequently reducing the occurrence of faulty components.

- Streamlines the process by removing the need for manual adjustment of workpieces.

- Enables autonomous operation, fostering complete automation and eliminating the necessity for operator intervention.

- Introduces enhanced data collection capabilities for process optimization.

- Supports adaptive machining by providing real-time feedback on workpiece conditions.

Touch Probe Types

| Repeatability(2σ) | <1um (50mm stylus, Speed of 60mm/min) | |

| Protective range | XY plane+/-12.5° | Z:6.2mm |

| Trigger force | XY 0.4~0.8N | Z: 5.8N |

| Transfer activation | Smart switch | |

| Repeatability(2σ) | <1um (50mm stylus, Speed of 60mm/min) | |

| Protective range | XY plane+/-12.5° | Z:6.2mm |

| Trigger force | XY 0.4~0.8N | Z: 5.8N |

| Transfer activation | M Code | |

FAQ of Touch Probes

1. What is a CNC probe?

The precision measuring instrument known as the CNC probe plays a vital role in enhancing the precision and efficiency of CNC machining procedures. Positioned and controlled meticulously, it comprises a sensor affixed to the CNC apparatus. Its primary function is to make contact with the workpiece’s surface, thereby facilitating the collection of essential data regarding its positioning and dimensions by the CNC system. Such information proves indispensable for various tasks including tool setup, workpiece assessment, and alignment. By automating measurements with utmost precision, touch probe diminish the necessity for manual involvement and mitigate the likelihood of errors during machining endeavors.

2. Are touch probes necessary for CNC Lathe?

Touch probes are not strictly necessary for CNC machining but are valuable tools. They enhance accuracy by automating measurements, reducing reliance on manual methods. Probes aid in tasks like tool setting, workpiece measurement, and alignment, improving overall efficiency and quality control. While not essential, they are widely used in precision manufacturing to optimize CNC processes.

3. How does a CNC probe work?

The CNC probe works by using precision sensors to detect physical contact with a workpiece. Mounted on the CNC machine, the probe is precisely positioned to touch the surface. When contact occurs, the probe sends a signal to the CNC system, prompting it to stop and record the positional data. This data is then used for various tasks such as tool setting, workpiece measurement, or alignment. The probe’s ability to accurately sense contact and provide positional information enhances the precision and efficiency of CNC machining processes, reducing reliance on manual measurements and minimizing errors in manufacturing.

4. What is the accuracy of touch probe?

The accuracy of a probe in CNC machining typically ranges from a few micrometers to a fraction of a millimeter. High-precision probes can achieve sub-micron accuracy. The accuracy depends on various factors, including the probe design, manufacturing quality, and calibration. In practical applications, the precision of touch probes is crucial for achieving tight tolerances in machining operations. Accurate measurements ensure that CNC machines can reliably position tools and workpieces, contributing to the overall precision and quality of the manufactured components.