Email: [email protected] Phone: (+86) 134 1323 8643

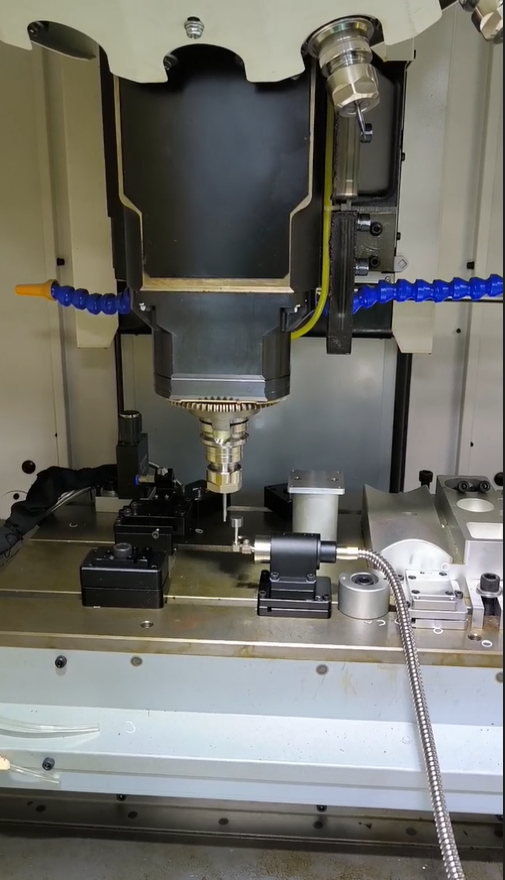

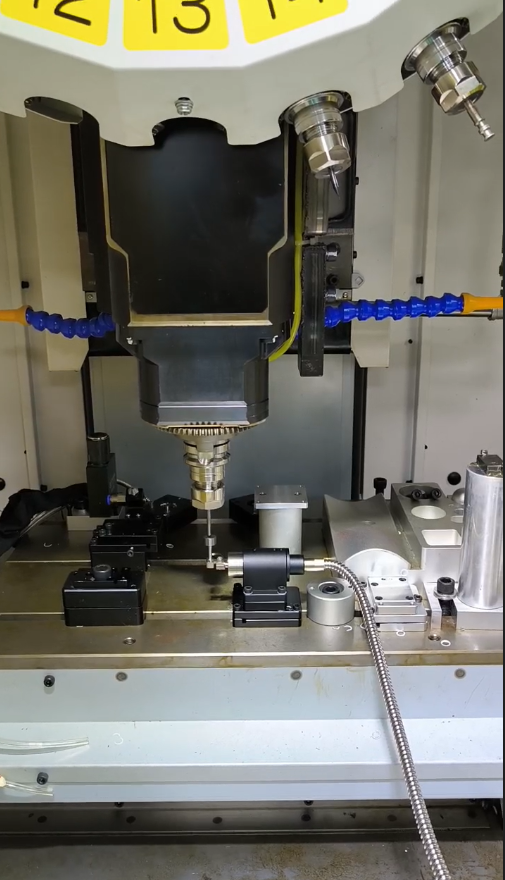

Tool Setter for CNC Mill DMTS-L

Tool Setter with Flexible Fine-Tuning Structure Design

3D Cable Tool Setter for ±X ±Y +Z Axis

- Tool length measurement

- Tool diameter measurement

- Automatic wear compensation

- Tool breakage detection

MODEL | DMTS-L |

Trigger direction | ±X, ±Y,+Z |

Output | A: NO |

Pre-stroke | None |

Protective range | XY plane:+/-12.5° Z: 6.2mm |

Repeatability precision(2σ) | ≤1um (speed: 50-200mm/min) |

Trigger life | >10million times |

Signal transmission mode | Cable |

Protection sealing level | IP68 |

Trigger force | XY plane: 0.4-0.8N Z:5.8N |

Touch pad material | Super-hard alloy |

Surface treatment | Grinding |

Contact Nominal Value | DC 24V,≤10mA |

Protetive tube | 3m, minimum radius 7mm |

LED light | Normal: OFF; active: ON |

Features of Tool Setter for CNC Mill

High Precision

- Six-point high rigidity positioning technology

- Micron-level assembly control process

- Repeat positioning accuracy(2σ)<1um

Anti-collision design

- The trigger shaft is placed horizontally to avoid main body being hit

- Weak connecting rod protection design to protect the core components from impact damage

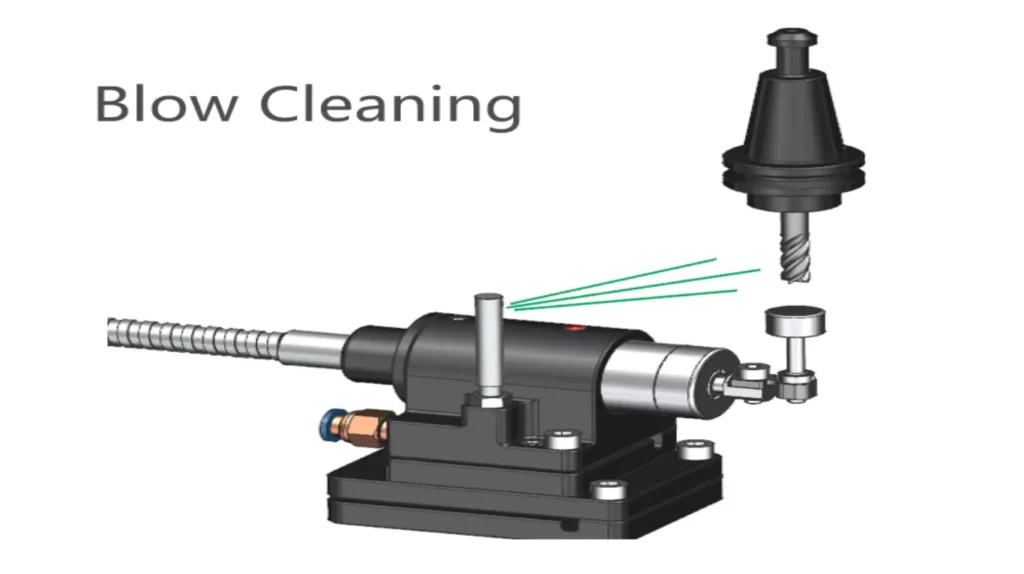

Blow cleaning

- The installation base comes with a blowing setting more practical

- Automatically blow air on the contacts to ensure the measurement accuracy and stability

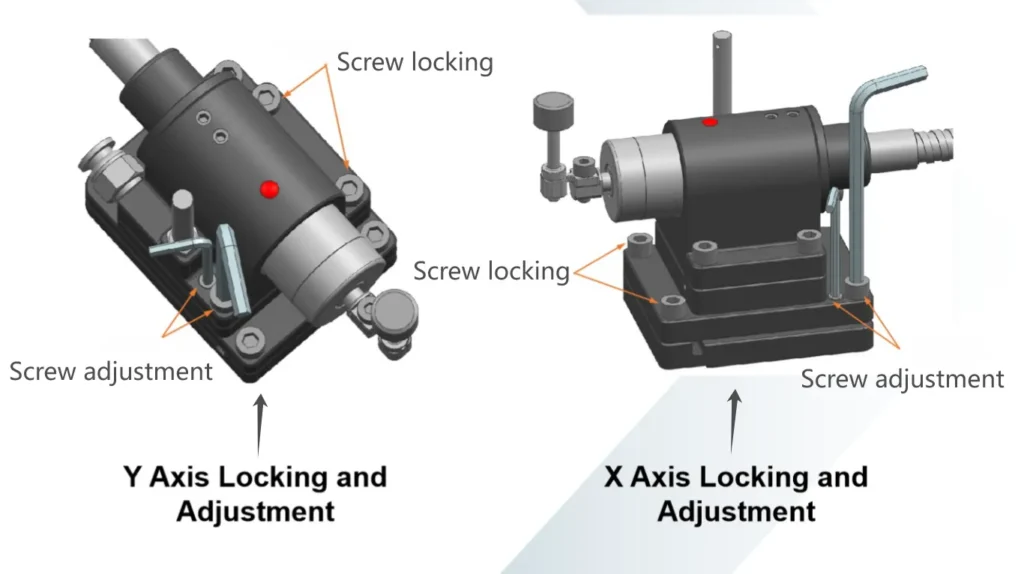

Flexible fine-tuning structure design

- XY independent adjustment design, easier horizontal adjustment

- The new elastomer fine-tuning structure design greatly improves the accuracy and efficiency of horizontal adjustment

IP68 Protection Level

- 10-meter water depth sealing test grade, exceeding IP68 standard

High stability

- Micro-damping reset technology, stable reset after product trigger

- ISO quality control system, end-to-end product quality control

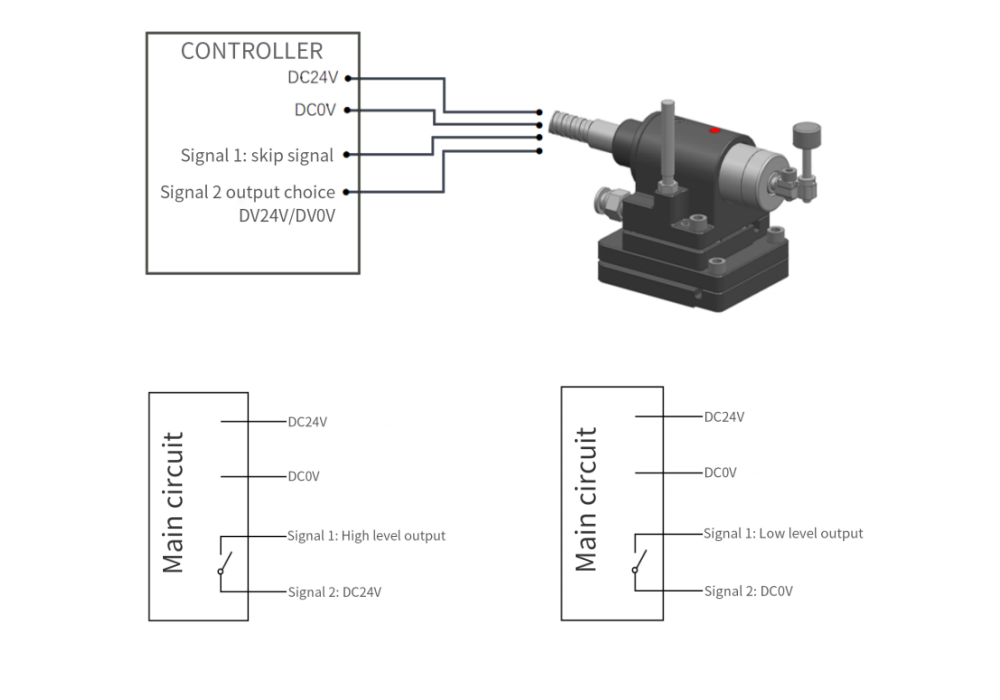

Electrical Diagram of Tool Setter for CNC Mill

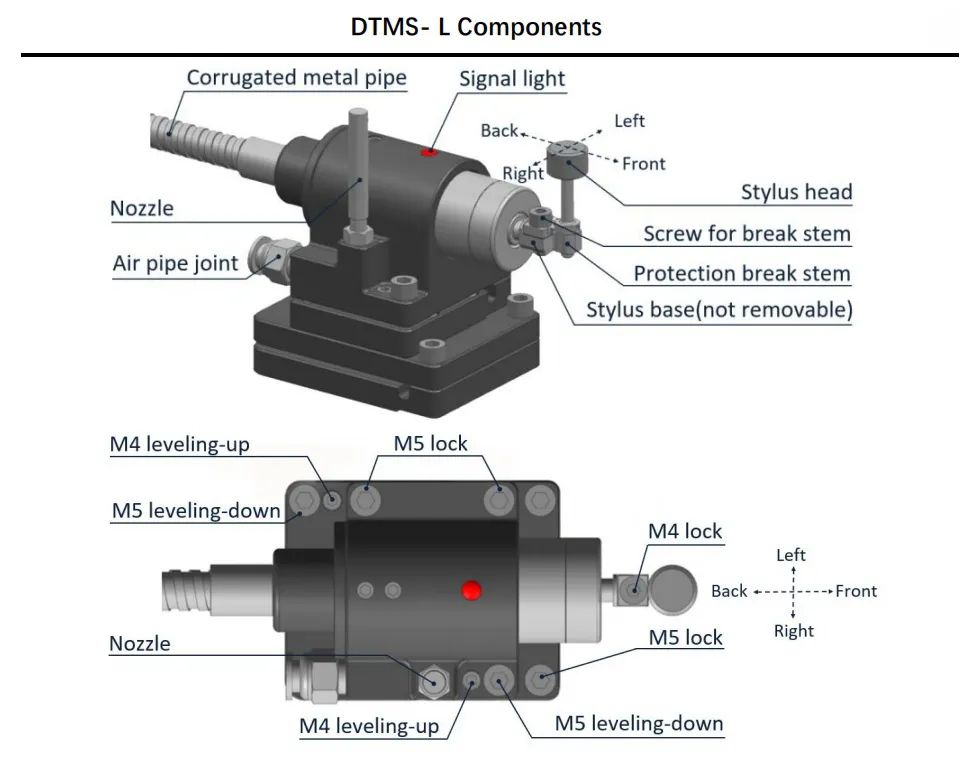

Components of Tool Setter for CNC Mill

Brief Introduction of Tool Setter for CNC Mill

DTMS- L is the tool setter for CNC mill, it can be tool setting operations on CNC machining centers. When performing tool length measurement and tool breakage detection, the tool is driven by the program to approach the stylus of the tool setter along the Z-axis. Set the radius compensation of the rotary tool on the X and Y axes of the machine tool. Alignment of stylus with machine axis by adjusting screw.

It can perform in-machine measurements of tool length and diameter, automatic compensation, and tool breakage detection. The triggering sensor utilizes a high-strength hard alloy structure and the micro-deformation autonomous restet technology developed by Qidu Metrology, ensuring excellent product stability and high repeatability in positioning accur.