Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

In the world of CNC machining, precision is paramount. A key player in achieving this accuracy is the CNC machine probe. This unassuming tool plays a vital role in setting up jobs, ensuring part quality, and ultimately, streamlining your production process. However, to maintain optimal performance, proper daily maintenance of your CNC machine probe is crucial. This guide delves into everything you need to know about CNC probes, from their function to troubleshooting common issues and, most importantly, proper daily maintenance routines.

What’s a CNC Machine Probe?

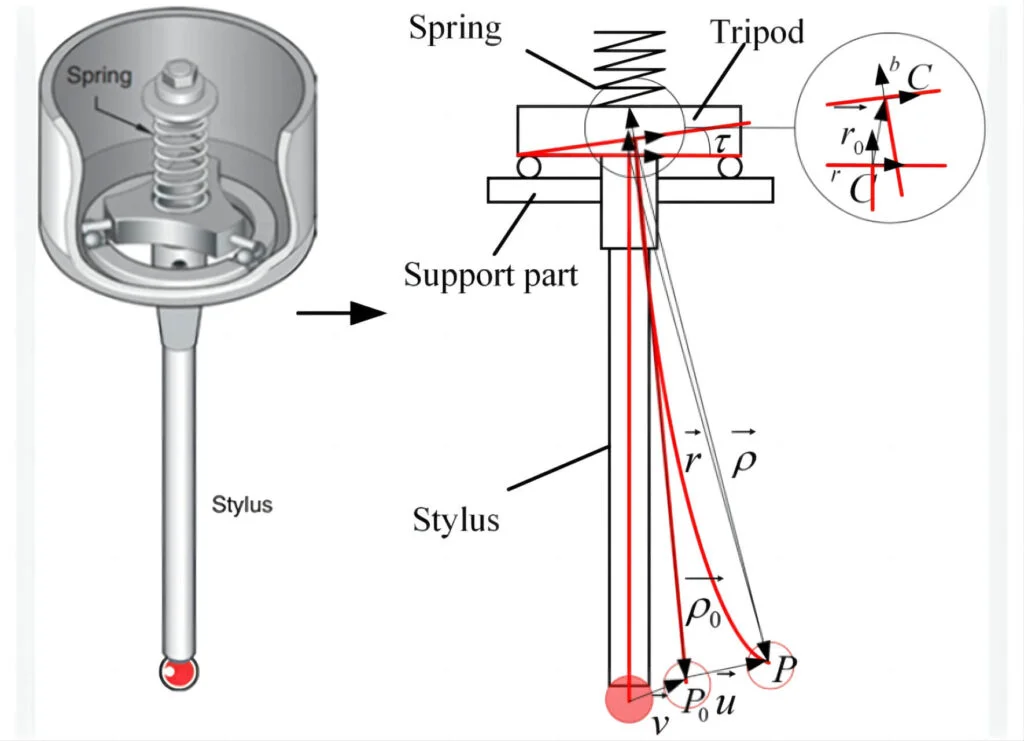

A CNC machine probe is a sensory device attached to the CNC machine’s spindle or tool changer. It typically features a spring-loaded stylus that makes contact with the workpiece surface. The probe transmits a signal to the CNC control unit upon contact, allowing the machine to determine the workpiece’s position and dimensions with high accuracy.

There are two main types of CNC machine probes:

- தூண்டுதல் ஆய்வைத் தொடவும் (TTP):This is the most common type. Upon contact with the workpiece, the stylus triggers a switch, sending a signal to the CNC.

- Non-Contact Probe:These probes use technologies like lasers or eddy currents to detect the workpiece’s proximity without physical contact. This is ideal for delicate materials or situations where maintaining constant pressure is undesirable.

Why Use the Probe in Your CNC Machine?

Integrating a CNC machine probe offers a multitude of benefits, including:

- மேம்படுத்தப்பட்ட துல்லியம்:Probes eliminate human error during manual tool setting and workpiece positioning. This translates to better part quality and reduced scrap rates.

- குறைக்கப்பட்ட அமைவு நேரம்:Probes automate the tool setting and work offset setting processes, significantly reducing setup times.

- Improved Efficiency:Faster setup times and fewer errors lead to increased production efficiency and overall cost savings.

- In-Process Inspection:Probes can be used for in-process inspection, verifying workpiece dimensions and detecting potential issues early on.

- Tool Wear Monitoring:By measuring tool length and diameter changes over time, probes can help predict tool wear and enable preventative maintenance.

Common Issues and Troubleshooting of CNC Machine Probe

Despite their robustness, CNC machine probes can encounter issues that can affect their performance. Here are some common problems and troubleshooting tips:

- False Triggers:This can occur due to a dirty stylus, damaged spring, or worn-out internal components. Clean the stylus, check for spring tension, and consult the manufacturer’s instructions for component replacement.

- Inaccurate Readings:Inconsistent readings could be caused by a loose probe connection, damaged cable, or misaligned stylus. Ensure secure connections, inspect the cable for wear, and verify proper stylus alignment.

- Communication Errors:Communication issues between the probe and CNC control unit can be caused by loose connections, faulty cables, or software glitches. Check connections, replace cables if necessary, and consult the user manuals for troubleshooting software errors.

For any complex issues beyond these initial steps, it’s always recommended to refer to the manufacturer’s service manuals or contact a qualified technician.

How to Maintain the CNC Machine Probe in the Proper Way

Maintaining your CNC machine probe is vital for ensuring its accuracy and longevity. Here are some key daily maintenance practices:

- Visual Inspection:Before each use, visually inspect the probe for any physical damage, including cracks, dents, or loose components. Pay close attention to the stylus tip for wear or contamination.

- Cleaning:Regularly clean the stylus with a dry, compressed air blast to remove dust, coolant, or debris that can affect triggering sensitivity. Avoid using solvents or lubricants unless specifically recommended by the manufacturer.

- Calibration:Regular calibration is essential for maintaining probe accuracy. The calibration frequency depends on usage and the manufacturer’s recommendations. It might involve setting a reference point or using dedicated calibration spheres.

- Cable Management:Inspect the probe cable for damage or wear daily. Ensure it’s properly secured to avoid snags or excessive tension during operation.

- Storage:When not in use, store the probe in a clean, dry location away from dust and contaminants. Follow the manufacturer’s storage recommendations for specific models.

முடிவுரை

By incorporating these simple daily maintenance practices into your routine, you can ensure the optimal performance of your CNC machine probe. This not only leads to improved part quality and production efficiency but also extends the life of your valuable equipment. Remember, a well-maintained probe is an investment in the precision and productivity of your CNC machining operations.

கத்ரீனா

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.