Email: [email protected] Phone: (+86) 134 1323 8643

I. Introduction

The CNC industry stands as a cornerstone of modern manufacturing, driving precision and efficiency in the production of various components across numerous sectors. Within this intricate ecosystem, the probe calibration emerges as a critical factor for enhancing operational excellence and maintaining high standards of quality. This article delves into the significance of probe calibration within the CNC industry, elucidating its impact on performance and productivity.

II. Understanding Probe Calibration

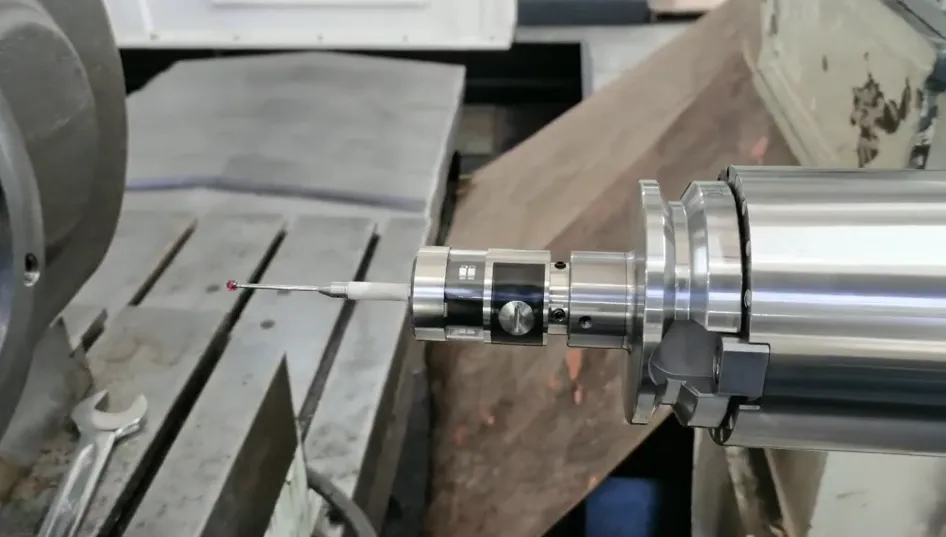

Probe calibration entails the meticulous adjustment and alignment of measurement devices within CNC machines to ensure accurate readings and precise machining processes. It serves as a fundamental practice to uphold the integrity of dimensional accuracy and geometrical precision in manufactured components. The calibration process involves fine-tuning the probing mechanisms to align with predefined standards and specifications.

The impact of probe reverberates throughout the CNC ecosystem, influencing the performance of machine tools and the overall manufacturing workflow. By ensuring the accuracy of measurements, probe calibration mitigates errors and deviations, thereby optimizing the efficiency and reliability of CNC operations.

III. Benefits of Probe Calibration in the CNC Industry

Enhanced Production Efficiency:

Probe calibration streamlines the manufacturing process by facilitating rapid and accurate measurements, thereby minimizing downtime and maximizing throughput. By automating inspection routines, calibrated probes expedite quality assurance procedures, enabling seamless integration into production workflows.

Improved Product Quality:

The precision afforded by probe translates into superior product quality, as deviations and inaccuracies are preemptively addressed during the machining process. Consistent calibration ensures adherence to design specifications, resulting in components of unparalleled accuracy and consistency.

Reduction of Waste and Costs:

Through precise measurement and control, probe calibration minimizes material waste and rework, optimizing resource utilization and reducing production costs. By preempting errors and deviations, calibrated probes mitigate the risk of costly defects and ensure optimal utilization of raw materials.

IV. How to Perform Probe Calibration

Performing probe calibration necessitates a systematic approach and adherence to best practices to achieve optimal results. The following steps outline the calibration process:

- Initialization and Setup: Ensure the CNC machine is properly configured for calibration, with all necessary tools and equipment readily available.

- Calibration Procedure: Execute the predefined calibration routine provided by the manufacturer, meticulously adjusting probe parameters to achieve alignment with reference standards.

- Verification and Validation: Conduct thorough verification tests to validate the accuracy and reliability of calibrated probes, ensuring alignment with designated tolerances.

- Documentation and Maintenance: Maintain comprehensive records of calibration activities, including dates, results, and any adjustments made. Implement regular maintenance protocols to sustain probe performance over time.

Adhering to these guidelines ensures the effectiveness and longevity of probe calibration efforts, underpinning the success of CNC operations.

V. Case Studies in the CNC Industry

Numerous success stories within the CNC industry exemplify the transformative impact of probe calibration on operational efficiency and product quality. Leading companies have leveraged calibrated probes to achieve remarkable improvements in productivity and precision, setting new benchmarks for excellence in manufacturing.

One such example involves the implementation of probe calibration techniques by a prominent aerospace manufacturer. By integrating calibrated probes into their CNC machining processes, the company achieved a significant reduction in cycle times and enhanced dimensional accuracy, resulting in substantial cost savings and heightened customer satisfaction.

VI. Common FAQs

Probe calibration entails a myriad of intricacies and nuances, prompting common questions and concerns among practitioners. Addressing these queries is essential to foster a comprehensive understanding of calibration principles and practices. Some frequently asked questions include:

Q: What are the typical intervals for probe calibration?

A: Typically, the intervals for probe calibration depend on various factors such as the type of probe, manufacturer’s recommendations, usage frequency, and environmental conditions. However, common intervals range from monthly to annually for most industrial probes.

Q:How can environmental factors affect calibration accuracy?

A: Environmental factors can significantly impact calibration accuracy by influencing the conditions under which the probe operates. Factors such as temperature fluctuations, humidity levels, air pressure changes, and exposure to contaminants can all affect probe performance and therefore calibration accuracy.

Q: What measures can be taken to troubleshoot calibration discrepancies?

A: Several measures can be taken to troubleshoot calibration discrepancies. These may include ensuring proper handling and storage of probes, checking for physical damage or contamination, verifying calibration standards, recalibrating using different methods or equipment, and assessing environmental conditions during calibration.

Q: Are there specialized training programs available for probe calibration?

A: Yes, there are specialized training programs available for probe calibration. These programs are often provided by manufacturers, industry associations, or training institutions and cover topics such as probe types, calibration procedures, troubleshooting techniques, and best practices for maintaining calibration accuracy.

By providing informative responses to these inquiries and offering relevant resources and support materials, practitioners can navigate the complexities of probe calibration with confidence and proficiency.

In conclusion, probe calibration stands as a linchpin for maximizing efficiency and excellence within the CNC industry. By upholding standards of precision and accuracy, calibrated probes enable manufacturers to achieve unparalleled levels of productivity, quality, and cost-effectiveness. Embracing probe calibration as a cornerstone of operational excellence empowers CNC practitioners to unlock new realms of performance and innovation in modern manufacturing.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.