Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

Introduction of Precision Touch Tips Manufacturing

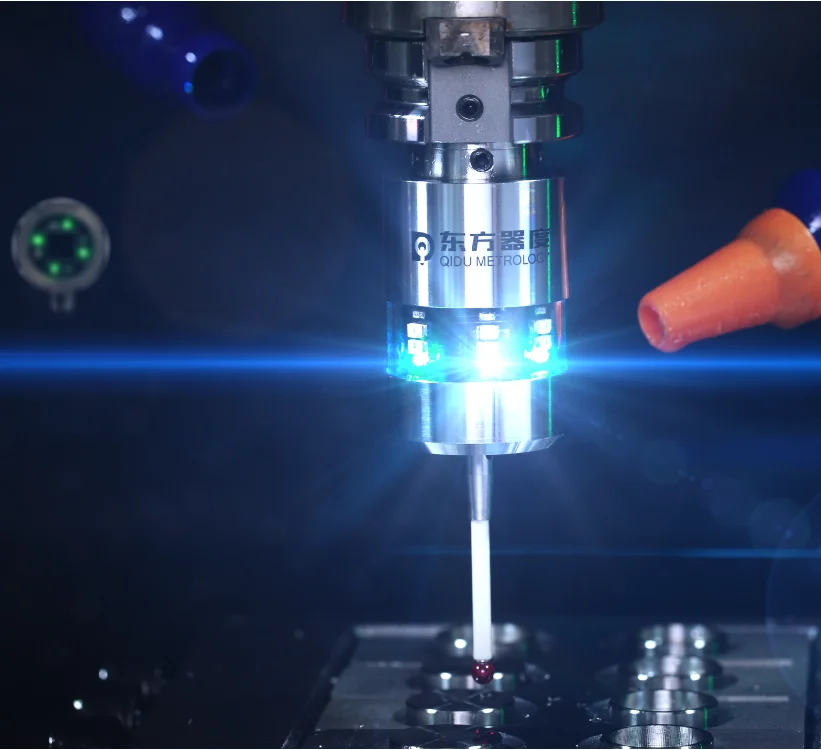

Unveiling the Future: Precision Touch Tips Manufacturing

The way we interact with technology has undergone a dramatic transformation. From clunky keyboards to bulky touchscreens, we’ve come a long way in achieving a seamless and intuitive user experience. At the forefront of this revolution lies the realm of precision touch tips, miniature marvels that translate the subtle nuances of our fingertips into digital commands. This article delves into the intricate world of precision touch tip manufacturing, unveiling its present landscape, future innovations, and the profound impact it has on various industries.

Understanding the Essence: What Are Precision Touch Tips?

Precision touch tips are microscopic, highly conductive components that reside at the tip of styluses or are integrated directly into touchscreens. They are meticulously crafted from specialized materials and boast features like high conductivity, pressure sensitivity, and durability. These miniature marvels bridge the gap between the physical and digital realms, translating the subtle touches and swipes of our fingers into precise digital signals.

The Current Landscape of Precision Touch Tips Manufacturing

The landscape of precision touch tip manufacturing is characterized by a surge in demand for advanced functionalities and miniaturization.

A. The Rise of Precision Engineering:

Advancements in precision engineering have opened doors to the creation of touch tips with incredible accuracy and responsiveness. Microfabrication techniques like photolithography and etching allow for the creation of complex, multi-layered structures with micron-level precision. This meticulous engineering ensures that every touch is registered flawlessly, leading to a superior user experience.

B. Key Players and Innovators:

Several leading companies are spearheading the development and innovation in precision touch tip manufacturing. These players include established tech giants like Apple, Samsung, and Google, alongside specialized material science and microfabrication companies.

C. Challenges and Limitations:

Despite the remarkable progress, the industry faces certain challenges. One hurdle lies in achieving the perfect balance between conductivity, durability, and cost-effectiveness. Additionally, miniaturization efforts push the boundaries of current manufacturing capabilities, demanding even more precise and sophisticated techniques.

Innovations Shaping the Future

The future of precision touch tip manufacturing promises exciting advancements driven by cutting-edge materials and technologies.

A. Advanced Materials and Nanotechnology:

The incorporation of advanced materials like graphene and other nanomaterials holds immense potential. These materials boast superior conductivity, strength, and flexibility, paving the way for even more responsive and durable touch tips.

B. Automation and Robotics in Manufacturing:

Automation and robotics are poised to play a pivotal role in streamlining the production process. High-precision robots can handle delicate tasks with unmatched accuracy, minimizing human error and ensuring consistent quality.

C. Integration of AI and Machine Learning:

The integration of artificial intelligence (AI) and machine learning (ML) offers exciting possibilities. AI-powered systems can monitor manufacturing processes in real-time, detect anomalies, and optimize production parameters. This will lead to increased efficiency, reduced waste, and consistent quality control.

The Impact of Precision Touch Tips Manufacturing in Various Industries

Precision touch tips are not just revolutionizing the way we interact with smartphones; they are impacting various industries in profound ways.

A. Automotive Sector: Revolutionizing Driving Experience:

The automotive industry is embracing touch tips for enhanced driver interaction. Haptic feedback-enabled touch controls integrated into steering wheels or dashboards can provide intuitive control without compromising safety. Additionally, touch tips can be used in advanced driver-assistance systems (ADAS) to facilitate gesture-based controls.

B. Consumer Electronics: Enhancing User Interaction:

Touch tips are instrumental in creating a more immersive and interactive experience for consumers. They can be used in styluses for tablets and laptops, offering pressure sensitivity for artistic creation or note-taking. Additionally, integration of touch tips in gaming controllers can provide haptic feedback and enhance the gameplay experience.

C. Healthcare and Medical Devices: Improving Patient Care:

Precision touch tips are finding applications in the medical field as well. They can be integrated into surgical tools, providing haptic feedback for improved precision during minimally invasive procedures. Additionally, touch tips can be used in medical wearables to monitor vital signs and interact with medical interfaces with greater ease.

Challenges and Opportunities in High-Frequency Modification

The prospect of high-frequency modification of touch tips, enabling functionalities like pressure mapping or temperature sensing, presents both challenges and opportunities.

A. Overcoming Technical Barriers:

Developing touch tips capable of handling high-frequency modifications requires overcoming technical hurdles. Miniaturization of sensors and integrating them seamlessly within the touch tip structure poses a significant challenge.

B. Addressing Regulatory and Safety Concerns:

Regulatory bodies will need to establish clear guidelines for the safety and efficacy of touch tips with advanced functionalities. Ensuring data security and privacy for sensor-equipped touch tips will also be crucial.

C. Exploring Market Potential and Growth Opportunities:

Despite the challenges, the potential market for high-frequency modified touch tips is vast. This technology has applications in areas like augmented reality (AR) and virtual.

Sustainability and Ethical Considerations

The burgeoning touch tip industry needs to address environmental and ethical concerns to ensure responsible and sustainable growth.

A. Environmental Impact of Manufacturing Processes:

Manufacturing processes for touch tips can involve hazardous materials and generate waste. Sustainable practices like using eco-friendly materials and adopting energy-efficient production techniques are crucial.

B. Ethical Sourcing of Raw Materials:

The ethical sourcing of raw materials used in touch tip production is another critical consideration. Companies should ensure that materials are not sourced from conflict zones or obtained through unfair labor practices.

C. Corporate Social Responsibility in the Industry:

Leading companies in the touch tip industry have a responsibility to promote social good. This can involve initiatives like supporting education and training programs in STEM fields, particularly for underrepresented groups.

Future Trends and Predictions

The future of precision touch tip manufacturing is brimming with exciting possibilities:

A. Miniaturization and Wearable Technology:

The relentless pursuit of miniaturization will lead to the creation of even smaller and more discreet touch tips. This paves the way for seamless integration into wearable technology like smartwatches and augmented reality (AR) glasses.

B. Personalized Touch Tips: Catering to Individual Needs:

Customization will be a key trend, with touch tips tailored to individual preferences. For instance, touch tips could be designed with varying degrees of pressure sensitivity or surface textures to cater to different user needs and preferences.

C. Globalization and Supply Chain Dynamics:

The global demand for touch tips will necessitate a robust and efficient global supply chain. Collaboration between manufacturers, material suppliers, and technology companies will be essential for ensuring consistent quality and ethical production practices.

Common Questions About Precision Touch Tips Manufacturing

Here are some of the most frequently asked questions regarding precision touch tip manufacturing:

A. What are precision touch tips, and how are they manufactured?

Precision touch tips are tiny, conductive components that form the tip of styluses or are integrated into touchscreens. They are meticulously crafted from specialized materials using microfabrication techniques like photolithography and etching.

B. How do precision touch tips enhance user experience in electronic devices?

Precision touch tips enable a more natural and intuitive user experience by translating the subtle touches and swipes of our fingers into accurate digital signals. This leads to improved responsiveness, pressure sensitivity, and overall user satisfaction.

C. What are the key challenges faced by manufacturers in producing high-quality touch tips?

Manufacturers face challenges in achieving the perfect balance between conductivity, durability, and cost-effectiveness. Additionally, miniaturization efforts push the boundaries of current manufacturing capabilities, demanding even more precise and sophisticated techniques.

D. How can businesses ensure the ethical and sustainable production of touch tips?

Businesses can ensure ethical and sustainable production by adopting eco-friendly practices, ethically sourcing materials, and promoting social responsibility initiatives within the industry.

E. What are some emerging trends in the precision touch tips industry?

The industry is witnessing trends like miniaturization, personalization of touch tips, and a growing emphasis on sustainability and ethical sourcing practices.

This comprehensive overview provides a glimpse into the fascinating world of precision touch tip manufacturing. As the technology continues to evolve, we can expect even more innovative applications that will redefine the way we interact with technology and shape the future of various industries.

Conclusion: A Future Shaped by Touch

The evolution of precision touch tip manufacturing signifies a paradigm shift in human-computer interaction. By bridging the physical and digital realms with unparalleled precision, these miniature marvels are transforming the way we experience technology across diverse sectors.

Looking ahead, the future of touch tips promises an even more immersive and intuitive user experience. Advancements in materials science and AI-powered manufacturing will pave the way for touch tips with enhanced functionalities and seamless integration into various devices. From personalized touch experiences to gesture-controlled interfaces, the possibilities are truly boundless.

However, ensuring the responsible and sustainable growth of this industry is paramount. Embracing eco-friendly practices, ethical sourcing, and robust social responsibility initiatives are crucial to minimize environmental impact and promote fair labor practices.

As we move forward, the journey of precision touch tip manufacturing holds immense potential to revolutionize the way we interact with technology. This journey promises not just a touch of convenience, but a transformation in the way we experience and shape the digital world around us.

ਕੈਟਰੀਨਾ

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.