Email: [email protected] Phone: (+86) 134 1323 8643

A Guide to Measuring Probes for CNC Routers

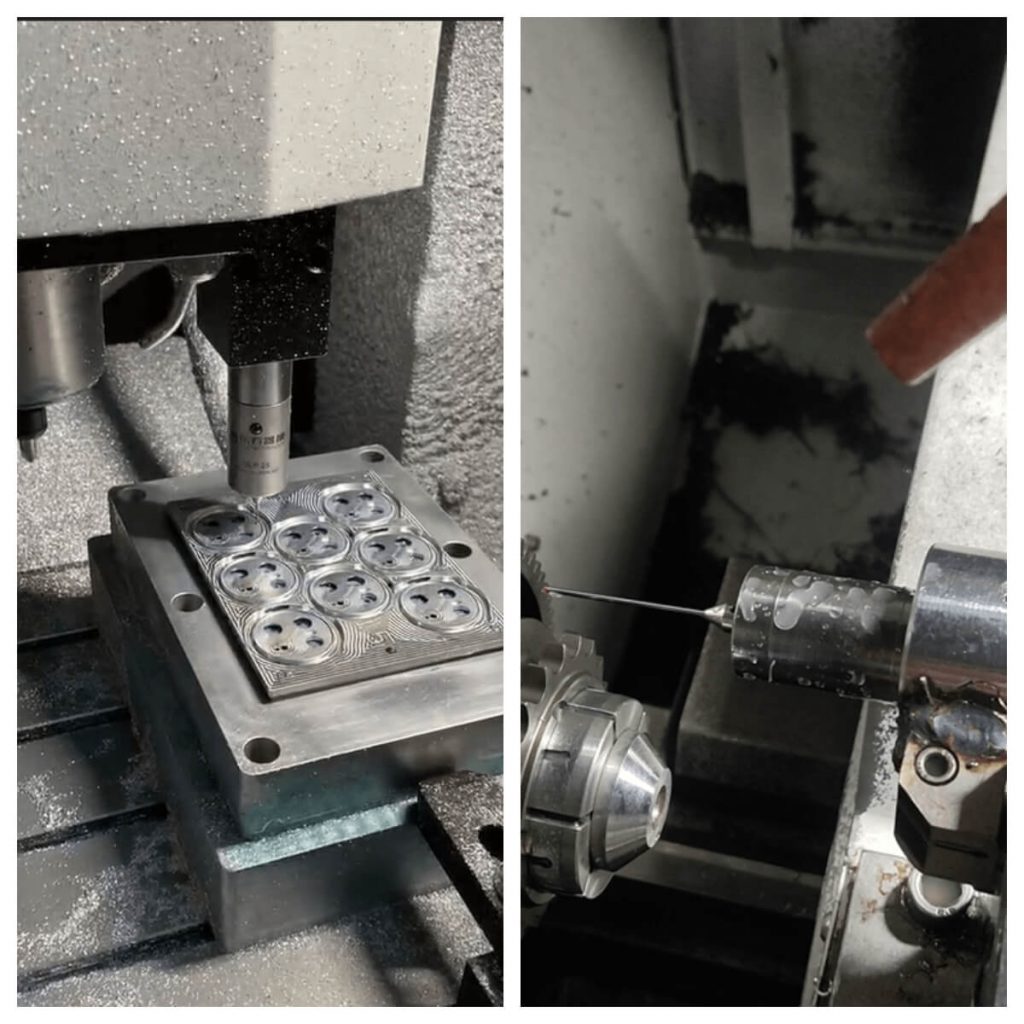

In the world of CNC routing, precision is key. Even a small deviation from the desired path can result in a ruined workpiece. That’s why it’s so important to use the right tools for the job, including a high-quality measuring probe.

A cnc probe is a device that is used to measure the position of a workpiece on a CNC router. It is typically used to set the zero point of the machine, as well as to measure the dimensions of the workpiece.

There are many different types of cnc probes available on the market, each with its own advantages and disadvantages. The best type of probe for you will depend on your specific needs and requirements.

In this article, we will discuss the different types of cnc probes available, as well as the factors to consider when choosing a probe for your CNC router. We will also provide some tips on how to use a probe to achieve the best possible results.

What is a Measuring Probe?

A probe is a sensor that is used to measure the position of an object. It is typically used in conjunction with a CNC machine to ensure that the machine is cutting or drilling in the correct location.

There are two main types of probes:

- Touch probes: These probes make contact with the surface of the workpiece to measure its position.

- Non-contact probes: These probes use a laser or other sensor to measure the position of the workpiece without making contact with it.

Touch probes are typically more accurate than non-contact probes, but they can also be more time-consuming to use. Non-contact probes are faster to use, but they may not be as accurate.

What is a CNC Router Touch Probe?

A CNC router touch probe is a type of cnc probe that is specifically designed for use with CNC routers. It is used to set the zero point of the machine, as well as to measure the dimensions of the workpiece.

CNC router touch probes are typically made of a hard material, such as tungsten carbide, to prevent them from being damaged when they come into contact with the workpiece. They are also typically equipped with a spring-loaded mechanism that allows them to retract if they encounter too much force.

What is a Touch Probe System?

A touch probe system is a complete set of tools that is used to measure the position of a workpiece on a CNC router. It typically includes a cnc probe, a mounting bracket, and a software program.

The software program is used to control the operation of the probe and to display the measurement results. The mounting bracket is used to attach the probe to the CNC router.

What is the Best Set of Tools for Using a CNC Probe?

The best set of tools for using a CNC probe will depend on the specific type of probe that you are using. However, there are some general tools that are useful for all types of probes.

These tools include:

- A magnifying glass: This can be used to help you see the exact location of the probe tip.

- A flashlight: This can be used to illuminate the workpiece so that you can see the probe tip more easily.

- A cleaning cloth: This can be used to clean the probe tip before and after each use.

Conclusion:

Using a CNC probe can help you to achieve precise and accurate results when using a CNC router. By choosing the right probe and using the right tools, you can ensure that your projects are completed to the highest possible standards.

Here are some additional tips for using a measuring probe:

- Always follow the manufacturer’s instructions when using a probe.

- Be sure to clean the probe tip before and after each use.

- Store the probe in a safe place when it is not in use.

If you are using a touch probe system, be sure to install the software program correctly.

- Calibrate the probe before each use.

- Take multiple measurements to ensure accuracy.

By following these tips, you can ensure that you are getting the most out of your probe.