Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

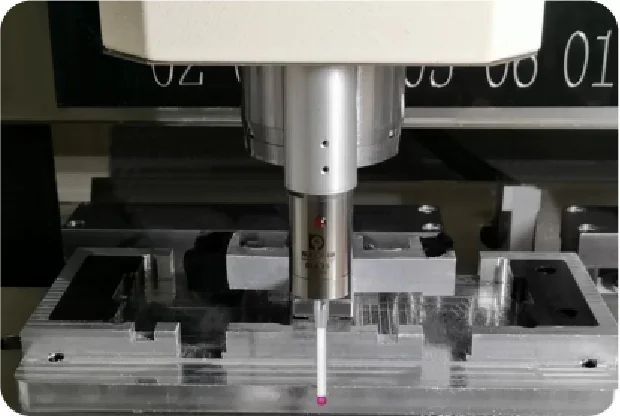

Measurement Device Touch Probe: The Key to Precision and Accuracy

A measurement device touch probe is a vital tool for any engineer or machinist who needs to take precise measurements. These probes are used in a variety of applications, including:

Coordinate Measuring Machines (CMM):

CMMs are used to measure the dimensions of complex parts. Touch probes are used to record the coordinates of points on the part’s surface.

CNC machines:

CNC machines are used to machine parts from raw materials. Touch probes are used to set the machine’s zero point and to measure the dimensions of the finished part.

Inspection:

Touch probes are used to inspect parts for defects. They can be used to measure the dimensions of features, such as holes and slots, and to check for surface finish.

There are many different types of measurement device touch probes available. The most common type is the tool touch probe. These probes are mounted on the spindle of a CNC machine or CMM. When the probe touches the surface of a part, it sends a signal to the machine’s controller. The controller then uses this signal to determine the position of the probe.

Another type of touch probe is the touch trigger probe. These probes are used to measure the position of a surface by detecting the moment when the probe makes contact with the surface. Touch trigger probes are often used in applications where high accuracy is required.

How to Choose the Right Measurement Device Touch Probe?

When choosing a measurement device touch probe, there are several factors to consider:

Accuracy:

The accuracy of a touch probe is determined by its repeatability and linearity. Repeatability is the ability of the probe to return to the same position when it is repeatedly touched to the same surface. Linearity is the ability of the probe to measure the distance between two points accurately.

Stylus tip:

The stylus tip of a touch probe is the part of the probe that comes into contact with the surface being measured. The stylus tip should be made of a material that is hard and wear-resistant, such as tungsten carbide.

Stylus force:

The stylus force is the amount of force that the probe exerts on the surface being measured. The stylus force should be high enough to ensure that the probe makes good contact with the surface, but low enough to avoid damaging the surface.

Environmental conditions:

The environmental conditions in which the probe will be used should also be considered. Some probes are designed for use in harsh environments, while others are more suited for use in clean, controlled environments.

Using a Measurement Device Touch Probe

Once you have chosen the right measurement device touch probe, you need to learn how to use it properly. Here are a few tips:

Calibrate the probe:

Before using the probe, you need to calibrate it. This involves touching the probe to a known surface and then adjusting the probe’s settings so that it reads the correct position.

Use the right stylus tip:

The stylus tip should be selected based on the material of the surface being measured. For example, a soft stylus tip should be used for measuring delicate surfaces, while a hard stylus tip should be used for measuring hard surfaces.

Apply the correct stylus force:

The stylus force should be adjusted so that the probe makes good contact with the surface without damaging it.

Keep the probe clean:

The probe should be cleaned regularly to prevent dirt and debris from building up on the stylus tip. This will help to ensure accurate measurements.

Conclusion

Measurement device touch probes are essential tools for any engineer or machinist who needs to take precise measurements. By following the tips in this article, you can choose the right probe for your needs and use it properly to get accurate results.