Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

For decades, radio waves have quietly revolutionized the way we connect and access information. But their influence extends far beyond communication. Sophisticated radio tools and probes are emerging as game-changers across industries, enabling inspections without harm and real-time insights into various processes. This article dives into the exciting world of radio tool probes, exploring their history, applications, advantages, and future possibilities.

Unveiling the Power of Radio Tool Probes

Imagine using invisible radio waves to gather valuable information about materials, objects, or even entire environments. That’s the magic of radio tool probes. These devices transmit and receive radio signals, acting like tiny detectives that unearth hidden details. Lower frequencies can pierce deep into materials, uncovering hidden flaws or moisture levels. Higher frequencies offer pinpoint accuracy for tasks like positioning objects, identifying materials, or even manipulating microscopic particles. The best part? They do all this without causing any damage, making them invaluable assets in a wide range of fields.

A Journey Through Radio Innovation

The story of radio tool probes is intricately linked to the evolution of radio technology itself. Scientists like James Clerk Maxwell laid the groundwork in the 19th century, but it was Guglielmo Marconi’s successful transatlantic radio transmission in 1901 that truly sparked the revolution. Early applications focused on communication, leading to radio broadcasting and radars in the first half of the 20th century. Later advancements in miniaturization, signal processing, and material science paved the way for the development of the sophisticated radio tools and probes we see today. These tools are now highly specialized, offering a vast array of capabilities depending on the specific use case.

Radio Tool Probe Applications in Various Industries

The applications of radio tool probes are as diverse as the industries themselves. Let’s explore a few examples:

- Keeping us Connected:In the world of telecommunications, radio tools ensure smooth operation by testing and optimizing networks. They identify signal weaknesses, pinpoint interference sources, and verify network integrity. These tools are also crucial for developing next-generation communication technologies by evaluating new materials and components.

- Healthcare Revolution:Medical imaging techniques like MRI rely on radio waves to create detailed pictures of the human body. The future holds promise for radio probes to deliver drugs directly to targets, remotely monitor vital signs, and even perform minimally invasive surgeries.

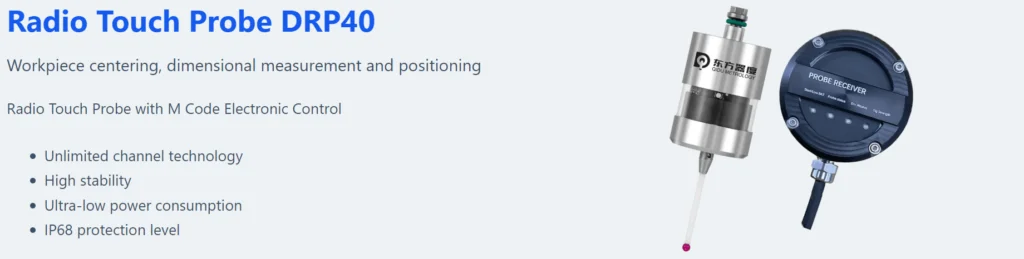

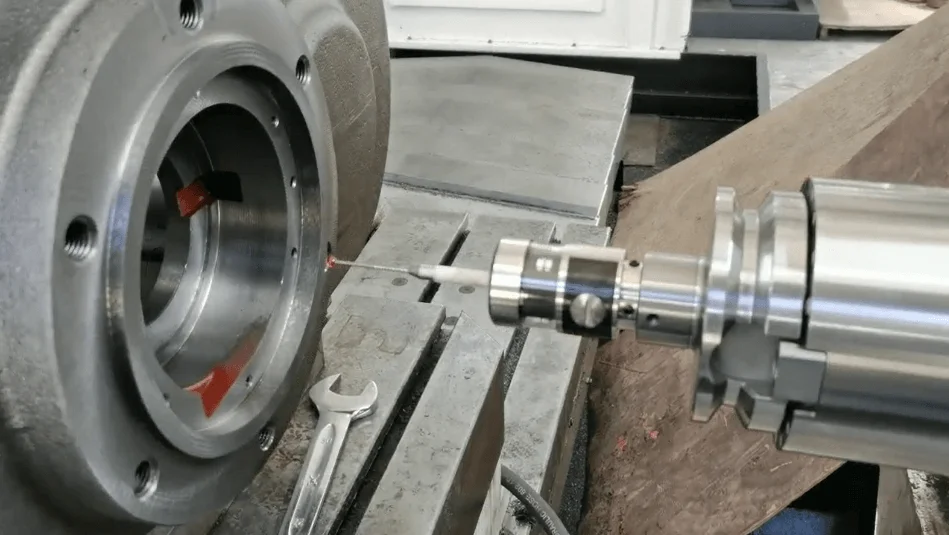

- Manufacturing Marvels:Radio tool probes are a mainstay in non-destructive testing within the manufacturing sector. They ensure product quality and safety by detecting flaws in welds, measuring coating thickness, and even monitoring the moisture content of raw materials. From cars to airplanes and buildings, radio tools play a vital role in quality control and optimizing production processes.

- Environmental Guardians:Radio tool probes can be deployed as environmental guardians, measuring soil moisture levels for efficient irrigation or even detecting underground water sources and tracking pollutant movement.

Advantages and Challenges of Radio Tool Probe

There are several advantages to using radio tool probes compared to traditional methods:

- Gentle Touch:Unlike destructive testing methods, radio tools don’t damage the target material, making them perfect for quality control and inspections.

- Real-Time Insights:These probes provide immediate data on various properties, allowing for quick adjustments and on-the-spot decision-making.

- Safety First:In hazardous environments or hard-to-reach locations, radio probes can be operated remotely, keeping workers safe.

- Seeing is Believing:Modern radio tools often come with advanced data visualization tools, allowing for a clear and comprehensive understanding of the collected data.

However, there are also some challenges to consider:

- Cost Factor:The upfront investment in advanced radio tools can be high, although the long-term benefits often outweigh the initial cost.

- Expertise Required:Operating and interpreting data from radio tools requires specialized training and knowledge.

- Signal Interference:Radio waves can be susceptible to interference from other sources, potentially affecting measurement accuracy.

Future Trends and Innovations of Radio Tool Probe

The future of radio tool probes is brimming with exciting possibilities. Here are some key trends to watch:

- Shrinking Wonders:As technology advances, radio probes will become even smaller, reaching previously inaccessible areas for inspection and measurement.

- AI Integration:The integration of Artificial Intelligence (AI) will enhance data analysis and decision-making based on information collected by radio probes.

- Multi-Frequency Power:Advancements in radio technology will lead to probes that operate at multiple frequencies simultaneously, allowing for a wider range of data acquisition.

- Wireless Revolution:Future radio probes may utilize wireless communication protocols for real-time data transmission and remote monitoring.

These advancements are not just theoretical. Let’s look at some real-world examples of how radio tool probes are transforming industries:

- Safer Skies:A major airline adopted radio frequency probes for inspecting composite materials used in aircraft wings. These probes can detect hidden cracks or delamination within the composite layers, allowing for preventive maintenance and reducing the risk of in-flight failures.

- Revolutionizing Food Production:In the agricultural sector, radio probes are being used to measure soil moisture content in real-time. This data helps farmers optimize irrigation practices, leading to more efficient water usage and increased crop yields.

- Enhanced Medical Diagnosis:Researchers are developing radio probes for early cancer detection. These probes can identify subtle changes in tissue properties that might be indicative of tumors, enabling earlier diagnosis and improving patient outcomes.

- Streamlining Construction Projects:The construction industry has seen a rise in the use of radio probes for locating underground utilities and ensuring safe excavation procedures. This not only prevents accidental damage to critical infrastructure but also optimizes construction timelines.

These examples highlight the vast potential of radio tool probes in revolutionizing various industries.

Addressing Common Concerns

Here are some of the most common questions regarding the use of radio tool probes in industries:

- Cost-effectiveness:While the initial investment in radio tools can be high, the long-term benefits often outweigh the cost. The non-destructive nature of the technology reduces the need for replacements and repairs, leading to significant cost savings in the long run. Additionally, improved process control and early detection of defects can prevent costly production delays or product recalls.

- Security Implications:The radio waves used in radio tools operate at specific frequencies and are typically low in power. However, proper security measures should be implemented to prevent unauthorized access or manipulation of data collected by the probes.

- Scalability:Radio tool probe technology is highly scalable. The specific type and configuration of probes can be customized to suit the needs of different industries and applications. Additionally, advancements in wireless communication protocols will allow for easier integration of these tools into existing infrastructure.

Conclusion: Shaping the Future

In conclusion, radio tool probes are rapidly transforming industries by offering non-invasive, real-time data acquisition capabilities. Their versatility, combined with ongoing advancements in miniaturization, AI integration, and wireless communication, promises to unlock even greater potential in the future. As industries strive for increased efficiency, safety, and sustainability, radio probes are poised to play a pivotal role in shaping the future of a wide range of sectors.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.