Email: [email protected] Phone: (+86) 134 1323 8643

For any lathe enthusiast, achieving precise cuts and maintaining consistent results is paramount. While skilled technique plays a crucial role, a powerful tool can significantly elevate your work: the lathe tool height setter. This seemingly simple device offers a wealth of benefits, transforming your workflow and enhancing the quality of your creations.

Understanding the Role of a Lathe Tool Height Setter

A lathe tool height setter is a specialized tool designed to ensure the cutting edge of your lathe tool rests at the exact center line of the work piece. This optimal positioning allows for clean, efficient cuts while minimizing tool wear and tear. Even minor variations in height can significantly impact your project. A tool set too low will struggle to remove material effectively, resulting in a rough finish and potentially damaging the tool itself. Conversely, a tool set too high will dig into the material, creating uneven cuts and potentially ruining your workpiece.

How Small Adjustments Can Make a Big Difference

Precision is key in the world of metalworking and woodworking. A lathe tool height setter enables you to make minute adjustments with incredible accuracy. This translates to a multitude of benefits, including:

- Improved surface finish:A correctly positioned tool creates smooth, clean cuts, eliminating chatter marks and unevenness.

- Reduced tool wear:Optimal tool height minimizes friction and pressure exerted on the cutting edge, extending the lifespan of your tools.

- Enhanced safety:Precise tool positioning reduces the risk of accidents that can occur when tools bind or dig into the workpiece.

- Streamlined workflow:By eliminating the need for tedious trial-and-error adjustments, you can set up your lathe quickly and efficiently.

The Basics of Lathe Tool Height Setter

What is a Lathe Tool Height Setter?

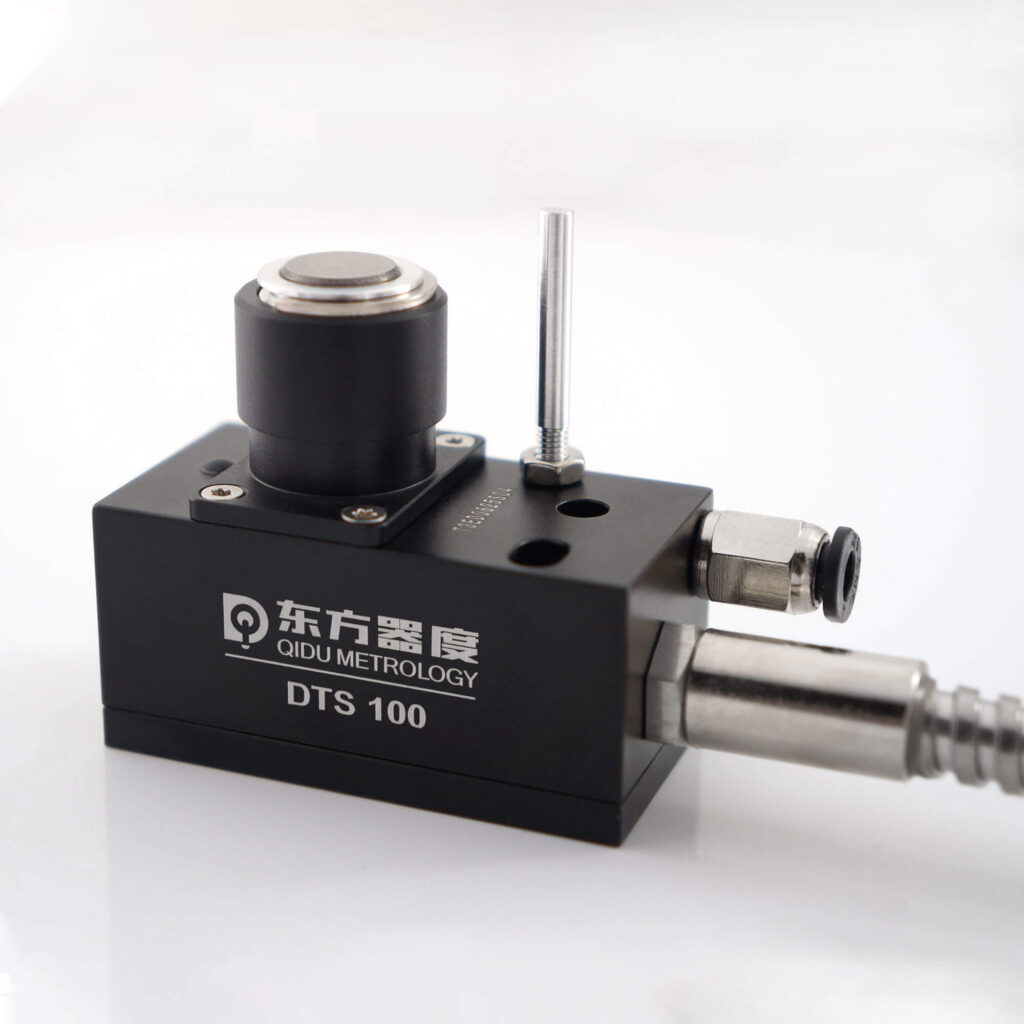

Lathe tool height setters come in various designs, but they all fulfill the same core function of enabling precise tool positioning. Some common types include:

- Dial indicators:Mounted on the tool post or carriage, these devices use a dial gauge to measure the distance between the cutting edge and the center line of the workpiece.

- Digital height gauges:Offering a digital readout for accurate measurements, these user-friendly gauges simplify the height setting process.

- Laser height gauges:Employing a laser beam to project a reference line, these advanced tools provide a highly accurate and convenient method for setting tool height.

Benefits of Using a Lathe Tool Height Setter

There are numerous advantages to incorporating a lathe tool height setter into your workflow:

- Enhanced Accuracy:Precise measurements guarantee consistent results, eliminating guesswork and wasted material.

- Increased Productivity:The time saved through quick and effortless tool setup allows you to focus on creating rather than troubleshooting.

- Improved Quality:Accurate tool positioning leads to clean cuts and a professional finish for your projects.

- Reduced Waste:Precise cuts minimize material loss, saving you money on stock.

- Extended Tool Life:Proper tool positioning reduces wear and tear on your lathe tools, saving you money in the long run.

Tips for Choosing the Right Lathe Tool Height Setter

When selecting a lathe tool height setter, consider these factors:

- Your budget:Dial indicators offer an affordable option, while digital and laser gauges come at a higher price point.

- Your skill level:For beginners, a user-friendly digital gauge might be ideal. Advanced users may prefer the precision of a laser gauge.

- The type of lathe you have:Ensure the setter is compatible with the size and configuration of your lathe.

Transforming Your Work with a Lathe Tool Height Setter

Improving Accuracy and Consistency

The most significant impact of a lathe tool height setter is the noticeable improvement in accuracy. By ensuring precise tool positioning, you can achieve consistent cuts across your entire project, eliminating inconsistencies and imperfections. This translates into professional-looking results that elevate your work.

Boosting Productivity and Time Management

Setting up your lathe for a project becomes a breeze with a tool height setter. No more fiddling with shims or relying on trial-and-error adjustments. The setter allows you to quickly and confidently establish the optimal tool height, saving valuable time you can dedicate to creating instead of troubleshooting.

Elevating the Quality of Your Craftsmanship

Precision cuts are the hallmark of quality craftsmanship. By ensuring your lathe tool is positioned correctly, you achieve clean, smooth cuts every time. This translates into a superior finish on your projects, whether you’re working with wood or metal.

Case Studies: Real-Life Examples of Success Stories

How Professional Woodworkers Utilize Lathe Tool Height Setters

Professional woodturners rely on lathe tool height setters to achieve the precise cuts necessary for creating intricate and delicate projects. A perfectly positioned tool allows them to craft thin walls on bowls and vessels without compromising their integrity. Additionally, for tasks like creating coves and beads, a tool height setter ensures consistent profiles throughout the piece. This level of precision translates to a refined aesthetic and minimizes the need for extensive sanding or rework, saving them valuable time.

Testimonials from Users Who Have Experienced the Transformation

“Since incorporating a lathe tool height setter into my workflow, my projects have reached a whole new level,” says John Miller, a seasoned woodworker. “The accuracy and consistency I’ve achieved are incredible. It’s not just about saving time; it’s about the confidence of knowing I can produce professional-looking results every single time.”

“As a beginner turner, I initially felt overwhelmed by the process of setting tool height,” shares Sarah Jones. “A digital tool height setter completely changed the game for me. The ease of use and clear measurements make it a breeze to get started and ensure my tools are positioned correctly.”

Tips and Tricks for Maximizing the Potential of Your Lathe Tool Height Setter

Setting Up Your Lathe Tool Height Setter for Optimal Performance

- Consult your lathe’s manual:Refer to the manufacturer’s instructions for specific guidelines on using a tool height setter with your lathe model.

- Secure mounting:Ensure the setter is firmly attached to the tool post or carriage to avoid any movement during operation.

- Calibrate regularly:Maintain the accuracy of your tool height setter by performing periodic calibrations according to the manufacturer’s recommendations.

Common Mistakes to Avoid When Using a Lathe Tool Height Setter

- Rushing the setup process:Take your time to ensure the tool setter is properly mounted and the tool height is meticulously adjusted.

- Forgetting to lock the setter:Double-check that all locking mechanisms are secure to prevent the tool from shifting during operation.

- Not considering tool shank size:Be mindful of the size of the tool shank you’re using, as it can affect the overall tool height.

Advanced Techniques for Advanced Users

For experienced turners seeking to push the boundaries of their craft, lathe tool height setters offer a platform for exploration:

- Multi-tool setups:By utilizing multiple tool height setters, you can pre-set various tools for different tasks, allowing for quick tool changes and streamlined workflows.

- Compound cuts:The precise control offered by a setter empowers you to make intricate compound cuts with confidence, unlocking new design possibilities.

- Advanced turning techniques:Techniques like outboard turning and negative rake angles benefit significantly from the precise tool positioning enabled by a setter.

People Also Ask About Lathe Tool Height Setters

1.What is the ideal height for a lathe tool setter?

There’s no single “ideal” height for a lathe tool height setter. The optimal setting will depend on the specific project you’re working on, the diameter of your workpiece, and the type of cut you intend to make. The setter itself functions as a measuring tool, allowing you to achieve the desired tool height relative to the center line of your workpiece.

2. Can a lathe tool height setter be used for different materials?

Yes, lathe tool height setters can be used for various materials, including wood, metal, and acrylic. The key factor is choosing the appropriate lathe tool for the material you’re working with. The setter itself functions universally to ensure the tool is positioned correctly regardless of the material.

3.How often should I calibrate my lathe tool height setter for accuracy?

The calibration frequency for your lathe tool height setter will depend on how often you use it and the conditions in your workshop. As a general rule, it’s recommended to calibrate the setter periodically, perhaps every few months or whenever you suspect its accuracy might be compromised. Always refer to the manufacturer’s instructions for specific calibration procedures.

By incorporating a lathe tool height setter into your workflow, you unlock a world of precision, efficiency, and elevated craftsmanship. This seemingly simple tool empowers you to achieve professional-looking results, streamline your projects, and take your turning skills to the next level. So, invest in a lathe tool height setter, and witness the transformation in your work!

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.