Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

Exploring Lathe Accessories, CNC Tool Presetters, and CNC Auto Parts

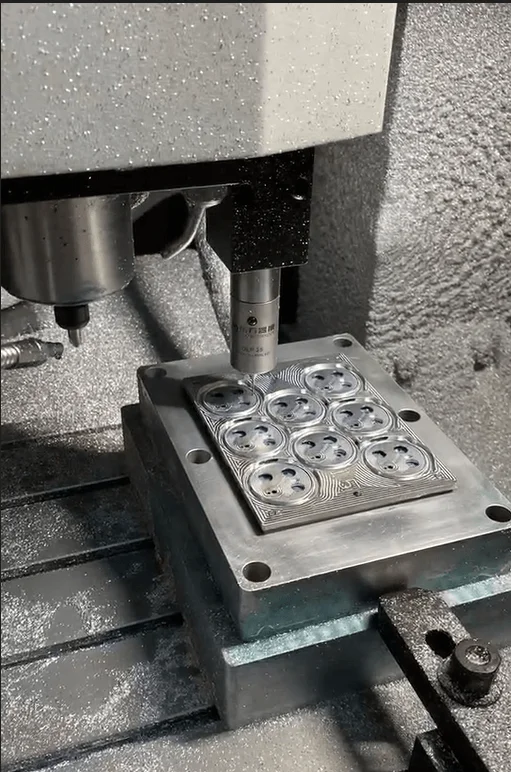

In the ever-evolving realm of CNC machining, the significance of utilizing advanced tools and accessories cannot be overstated. This article delves into the crucial role of lathe accessories, tool presetters for CNC machines, and CNC auto parts in achieving optimal precision and efficiency. By understanding the capabilities of these tools, manufacturers can enhance their machining processes, ultimately leading to higher-quality products.

Lathe Accessory: A Cornerstone of Precision

In the realm of CNC machining, the lathe is a fundamental tool for shaping materials with unparalleled accuracy. A key component that significantly contributes to the precision of lathes is the lathe accessory. These accessories play a pivotal role in the machining process by allowing for intricate detailing and fine-tuning of materials. From cutting tools to specialized attachments, the right accessory can make all the difference in achieving the desired precision in machining.

As CNC machining continues to advance, the demand for higher precision has led to the development of specialized lathe accessories. These accessories are designed to meet the exacting requirements of modern manufacturing processes. Whether it’s a precision cutting tool or a specially crafted attachment, the lathe accessory serves as a cornerstone in the pursuit of perfection in CNC machining.

Tool Presetters for CNC Machines: Streamlining Precision Setup

One of the challenges in CNC machining is the need for precise tool setup. This is where presetters for CNC machines come into play. These sophisticated devices allow machinists to accurately measure and set tools before they are mounted on the CNC machine. By automating the tool setup process, presetters eliminate the margin of error associated with manual measurements, ensuring that each tool is precisely positioned for optimal performance.

The CNC machining industry has witnessed a paradigm shift with the integration of presetters into machining workflows. Machinists can now save valuable time and resources by using these automated devices to measure, set, and verify tools with unparalleled accuracy. This not only enhances the overall efficiency of CNC machining operations but also contributes to the longevity of cutting tools, reducing the need for frequent replacements.

CNC Auto Parts: Precision in Every Component

In the realm of CNC machining, the production of auto parts demands an extraordinary level of precision. Numerically controlled machined auto parts, ranging from engine components to intricate transmission parts, require meticulous attention to detail. Achieving the desired precision in the manufacturing of these parts is a complex process that involves the integration of cutting-edge technologies and tools.

The integration of numerically controlled machined auto parts into the manufacturing process brings forth a new era of precision engineering. Computer Numerical Control technology allows for the creation of intricate and highly accurate auto components. From cylinder heads to brake components, every part is precisely machined to meet the stringent quality standards of the automotive industry.

Optimizing Efficiency: The Best Set of Tools for CNC Machining

In the pursuit of excellence in CNC machining, the importance of having the best set of tools cannot be overstated. A combination of precision lathe accessories, advanced presetters, and numerically controlled machined auto parts creates a synergy that optimizes efficiency in machining operations. Manufacturers who invest in the right tools not only achieve superior precision but also experience increased productivity and reduced downtime.

The best set of tools goes beyond individual components; it encompasses the integration of technologies that complement each other seamlessly. From the initial design phase to the final production of CNC auto parts, every step in the process benefits from the precision and efficiency that result from using the best tools available.

Conclusion: Precision Redefined in CNC Machining

In conclusion, the world of CNC machining is continually evolving, with precision at its core. Lathe accessories, presetters for CNC machines, and numerically controlled machined auto parts collectively contribute to redefining precision in the manufacturing industry. As technology advances, manufacturers must stay abreast of the latest tools and accessories to remain competitive and deliver products of the highest quality. By understanding the capabilities of these essential components, the CNC machining industry can continue to push the boundaries of precision and efficiency, shaping the future of manufacturing.