Email: [email protected] Phone: (+86) 134 1323 8643

Laser Tool Setter Series

Multifunctional Laser Tool Setter for ±X ±Y +Z

- Tool damage inspection

- Tool length measurement

- Tool radius measurement

- Tool shape measurement

- Tool shape monitoring

- Single-edge cutting monitoring

- Wear compensation

- Axis compensation

- Tool tip monitoring

- Chamfer tool monitoring

- Conical tool monitoring

| Item No. | DNC56 | DNC86 | DNC168 |

| Tool Daimeter (Center) | Φ0.03-50 | Φ0.03-80 | Φ0.03-160 |

| Tool Diameter (Tangent) | Φ0.03-60 | Φ0.03-110 | Φ0.03-320 |

| Repeatability(2σ) | ±0.1μm (up to controller) | ||

| General Complex Accuracy(2σ) | ±1μm | ||

| Laser Type | power<1mW, wavelength 680nm | ||

| Laser Beam Alignment | With adjusting mounting plate | ||

| Supply Voltage | 50mA @ 24VDC | ||

| Power Protection | Replaceable fuse | ||

| Output Signal | max currency 50mA, max voltage ±50V | ||

| Signal Output Mode | 5m-8core shielded twisted pair,oil resistance | ||

| Pneumatic | 4mm tube(43psi~87psi) | ||

| Life | >1 million cycles | ||

| Sealing | IP68 | ||

| Body Material | Aviation aluminum | ||

| Storage Temperature | -10°C~70°C | ||

| Working Temperature | 5°C~50°C | ||

Features of Laser Tool Setter

High Precision

- Highest repeatability(2σ) ≤ 0.1um

- Comprehensive accuracy(2σ) ≤ 1um

Non-contact measurement

- Non-contact laser measurement, which won’t damage the tool

- Measurable minimum tool diameter is 0.03mm

High Stability

- Laser trigger signal is used for stronger signal stability

- Anti-drip function design, actively prevent false alarms

High Protection

- IP68 for 10 meters water depth protection

- Innovative two-tower independent safety protection system

Richer Features of Laser Tool Setter

- Tool length, tool diameter, tool swing and contour can be detected

- Tool diameter 0.03~168mm can be measured for large application range

- No tool hardness limitation, applicable to all hardness tool measurements

- Automatically updating the tool offset error

- Monitor and compensate for the thermal deformation of the machine tool spindle

- Detected at extremely high speed, and can truly simulate actual working conditions.

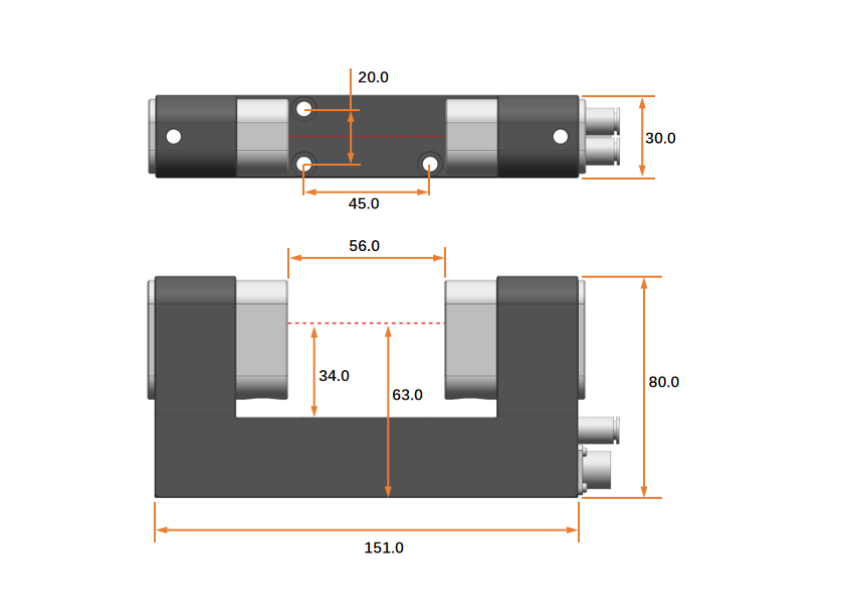

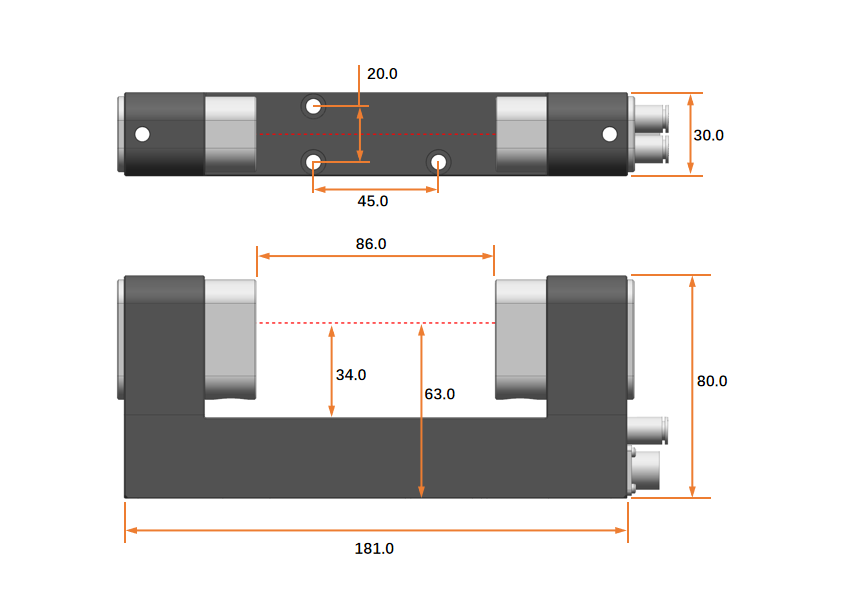

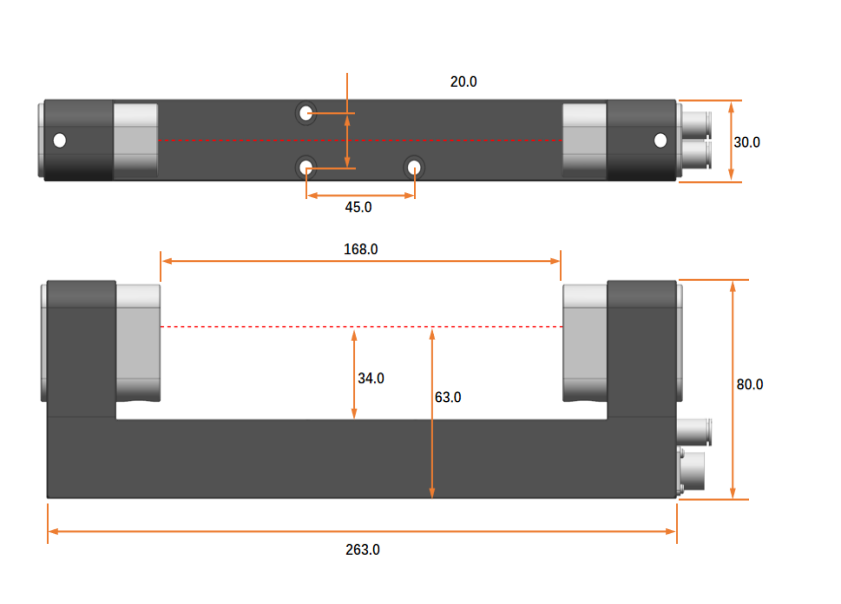

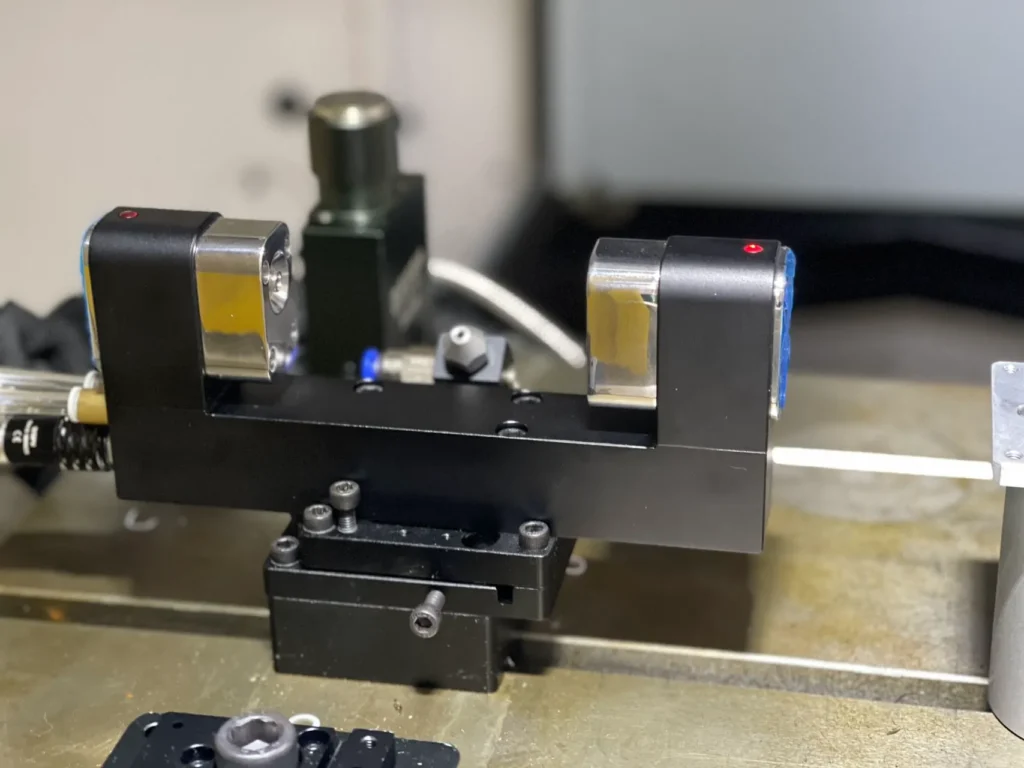

Different size for Laser Tool Setter Series

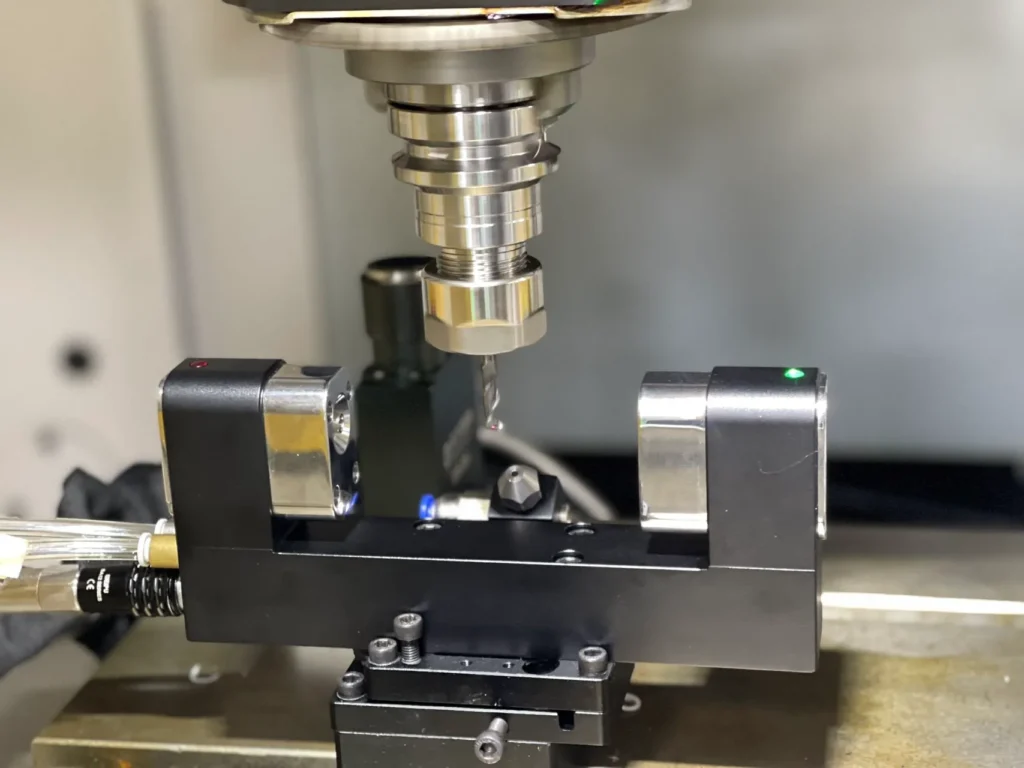

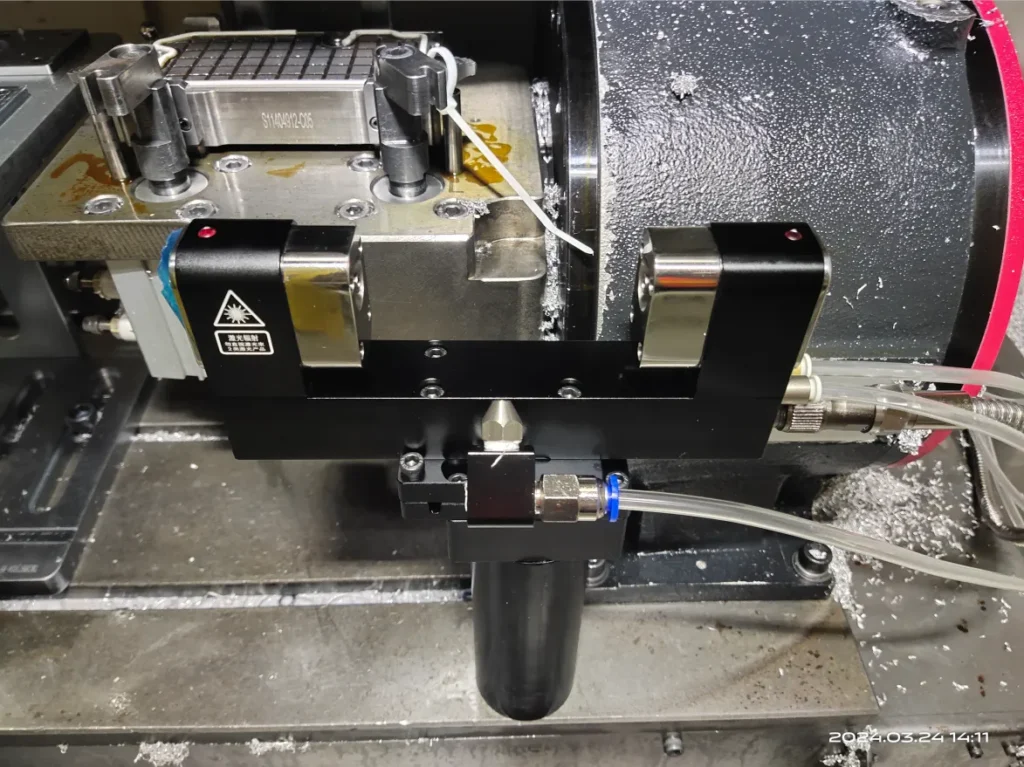

Details of Laser Tool Setter Series

DNC56 is suitable for small CNC machining equipment such as precision engraving machines, high-speed polishers, and glass machines. It enables high-precision, high-speed non-contact tool and tool damage detection as well as contour inspection fro various delicate diamter tools where contract force may lead to tool damager, such as glass processing grinding heads.

DNC86 is suitable for medium-sized CNC machine tools such as CNC maching centers, CNC lathe and horizontal machining centers. It enables high-precision, high-speed non-contact tool and tool damage detection, as well as contour inspection for various solid tools, shaping tools and medium to samll diameter disc cutters.

DNC168 is suitable for large CNC maching centers such as gantry CNC milling machines. It enables high-precison, high-speed non-contact tool setting and tool damage detection for disc nutters and various types of large-diameter profile tools.

Function of Laser Tool Setter

- Automatic tool length measurement and update automatically

- Automatic tool diameter measurement and update automatically

- Contour point measurement such as ball-nose custter, toroidal cutter, etc.

- Tool wear measurement and automatic

- Tool break detection, automatic alarm compensation

Advantage of Laser Tool Setter

- Automated measurement is highly time-efficient

- Outstanding quality and extremely low defect rates

- Enables a closed-loop workflow

- Unmanned and automated operation mode

- Measures and monitors various tool types, shapes, etc

- Highly dynamic measurement of all tool characteristics

- Reduces measurement and inspection time by up to 60%

- Adjusts speed dynamically based on the tool’s rated RPM

- Reliable measurements even in the presence of coolant

- Filters out dirt and coolant residues adhering to the tool

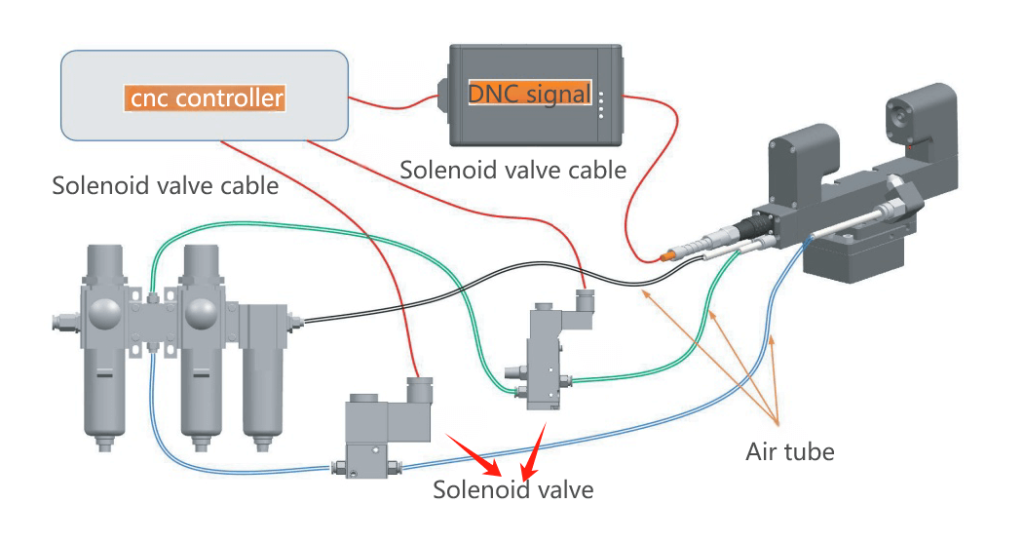

Circuit Diagram of Laser Tool Setter