Email: [email protected] Phone: (+86) 134 1323 8643

Milling machine probes are integral to modern machining and metalworking. These devices enhance precision and efficiency by ensuring accurate measurement and guidance during cutting operations. In this article, we’ll delve into the various designs and functions of milling machine probes, shedding light on their vital role in the industry.

Introduction to Milling Machine Probes

In the realm of metalworking, precision and accuracy are paramount. Milling machine probes are pivotal in achieving these standards. These devices interface with milling machines to provide crucial data that guides cutting tools and positions workpieces accurately. By doing so, they enhance the quality and efficiency of machining processes. This article explores the different types and functionalities of milling machine probes, highlighting their significance in various applications.

1.Mechanical Probes: Simplicity and Robustness

Mechanical probes, the more traditional type, rely on physical components like gears and levers to relay the cutting tool’s position to the milling machine.

- Advantages of Mechanical Probes

Mechanical probes are celebrated for their straightforward design and affordability. They excel in basic positioning tasks and are less affected by environmental changes such as temperature and humidity, which can impact the precision of electronic systems.

- Ideal Applications

Due to their resilience and simplicity, mechanical probes are perfect for operations that do not require high precision or complex movements. They are also favored in settings where cost-effectiveness is a priority.

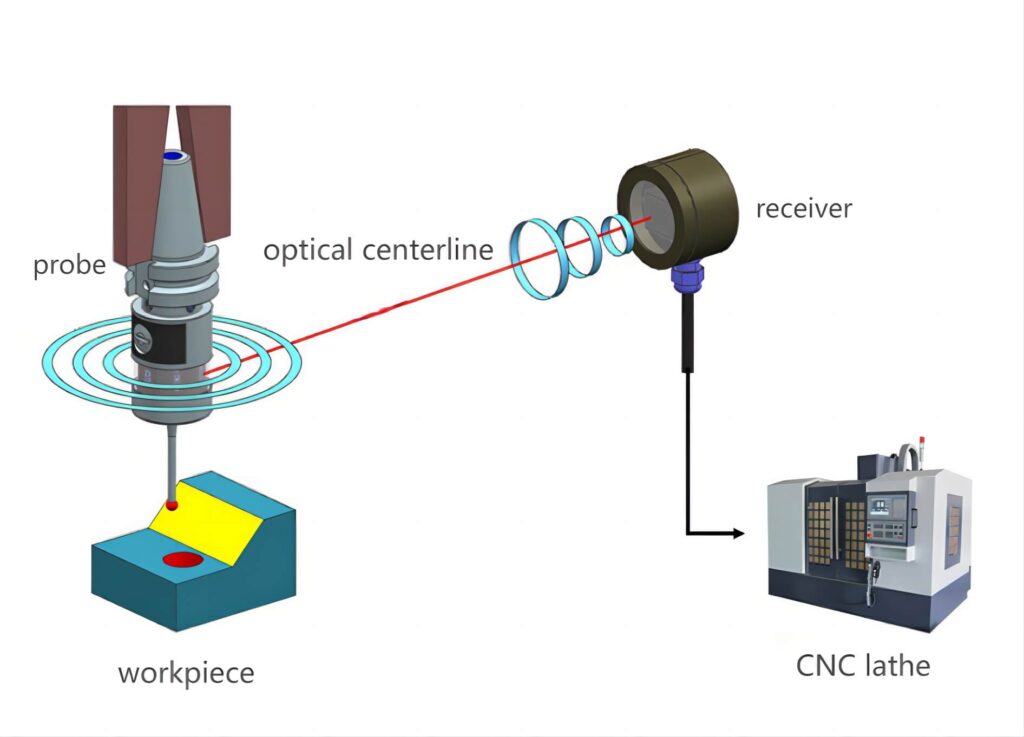

2.Electronic Probes: Precision and Versatility

Electronic probes utilize sensors and electronic circuits to offer advanced capabilities and precision in machining processes.

- High Precision and Multi-Axis Capabilities

These probes provide superior accuracy and can measure multiple axes simultaneously, making them indispensable for sophisticated and intricate machining tasks. Their ability to offer real-time feedback on the workpiece’s position further enhances their utility in modern manufacturing environments.

- Complex Cutting Operations

Electronic probes are programmable, allowing them to perform a range of complex cutting operations. This flexibility makes them ideal for advanced machining applications that demand high precision and adaptability.

3.Integrated Probes as Cutting Tools

Some milling machine probes are designed to function as cutting tools themselves, offering dual functionality.

- End Mills with Integrated Probes

End mills equipped with integrated probes are particularly useful in roughing operations, where they facilitate rapid material removal. This dual capability not only shortens machining time but also reduces operational costs by combining measurement and cutting in a single tool.

4.Probes in Multifunctional Machining

Milling machine probes are not limited to milling alone; they are also used in conjunction with other machining processes.

- Applications in Turning and Grinding

In processes like turning and grinding, probes can measure critical parameters such as the diameter of a workpiece or its surface roughness. This data is invaluable for maintaining quality control and ensuring the efficiency of the overall machining process.

Conclusion of Milling Machine Probes

Milling machine probes are indispensable in modern machining and metalworking, offering essential functions that range from positioning and orientation to cutting and measuring. Whether you opt for mechanical or electronic probes, understanding their unique advantages and applications can significantly enhance your machining processes. For professionals in the industry, leveraging the right type of probe is key to achieving superior precision, efficiency, and quality in their work.

In summary, as technology evolves, so does the role of milling machine probes. They continue to advance, providing ever more precise and versatile solutions that meet the growing demands of the metalworking industry.

Milling Machine Probes: FAQ

1. What Are Milling Machine Probes?

Milling machine probes are devices used in metalworking and machining to ensure precise measurement and guidance during cutting operations. They help in positioning the workpiece accurately and maintaining the correct orientation of the cutting tools.

2. What Are the Main Types of Milling Machine Probes?

Milling machine probes can be broadly classified into two categories:

- Mechanical Probes: These use physical components like gears and levers to transmit the position of the cutting tool to the machine. They are known for their simplicity and cost-effectiveness.

- Electronic Probes: These employ sensors and electronic circuits to provide high precision and flexibility. They are capable of performing complex tasks and offering real-time feedback.

3. What Are the Advantages of Mechanical Probes?

- Simplicity and Affordability: Mechanical probes have a straightforward design and are generally more affordable.

- Environmental Resilience: They are less affected by changes in temperature and humidity compared to electronic probes.

- Ideal for Basic Applications: They are best suited for tasks that require basic positioning and do not demand high precision.

4. What Are the Benefits of Using Electronic Probes?

- Presisi Tinggi: Electronic probes offer superior accuracy, essential for detailed and intricate machining.

- Real-Time Feedback: They provide instant data on the workpiece’s position, enhancing control and quality.

- Programmability: They can be programmed for complex operations and can measure multiple axes simultaneously.

5. Can Probes Be Used as Cutting Tools?

Yes, some probes are designed to function as cutting tools. For example, end mills with integrated probes can perform roughing operations while simultaneously measuring the workpiece, which helps in reducing machining time and costs.

6. How Are Probes Used in Multifunctional Machining Processes?

Milling machine probes are versatile and can be used in conjunction with other machining processes like turning and grinding. In these scenarios, they can measure parameters such as diameter and surface roughness, aiding in process control and quality assurance.

7. Why Are Milling Machine Probes Important?

Milling machine probes are crucial for achieving precision and efficiency in machining processes. They ensure accurate positioning and orientation of the workpiece and cutting tools, which is essential for maintaining high-quality standards in metalworking.

8. How Do I Choose Between Mechanical and Electronic Probes?

- Mechanical Probes: Choose these for basic, cost-effective applications where environmental conditions might vary and high precision is not critical.

- Electronic Probes: Opt for these when high precision, complex operations, and multi-axis measurements are required.

9. What Are the Key Considerations for Using Milling Machine Probes?

- Application Needs: Assess whether your operations require basic positioning or advanced, high-precision measurements.

- Environmental Conditions: Consider the impact of temperature and humidity on probe performance.

- Budget Constraints: Determine whether the cost-efficiency of mechanical probes or the advanced capabilities of electronic probes align better with your budget.

10. How Do Milling Machine Probes Enhance Machining Processes?

By providing accurate measurements and guidance, milling machine probes help in optimizing machining processes. They reduce errors, save time, and lower operational costs, all while maintaining or improving the quality of the finished product.

For professionals in the metalworking industry, understanding and utilizing the right type of milling machine probe is essential for achieving optimal results.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.