Email: [email protected] Phone: (+86) 134 1323 8643

The world of CNC machining relies heavily on precision. Enter the trusty probe – a technological marvel that’s been around for longer than you might think. Buckle up as we explore the fascinating history of Probe CNC development!

Early Seeds: The 1920s and Beyond

The story of probes can be traced back to the 1920s, with the emergence of inductive micrometers. These early tools laid the groundwork for the more sophisticated probes that would come later. However, it wasn’t until the late 1950s that we saw a real surge in development.

The Rise of CMMs and the Trigger Probe (1950s-1970s)

The arrival of Coordinate Measuring Machines (CMMs) in the late 1950s acted as a catalyst for probe development. These machines demanded a more precise way to measure parts, and probes stepped up to the challenge.

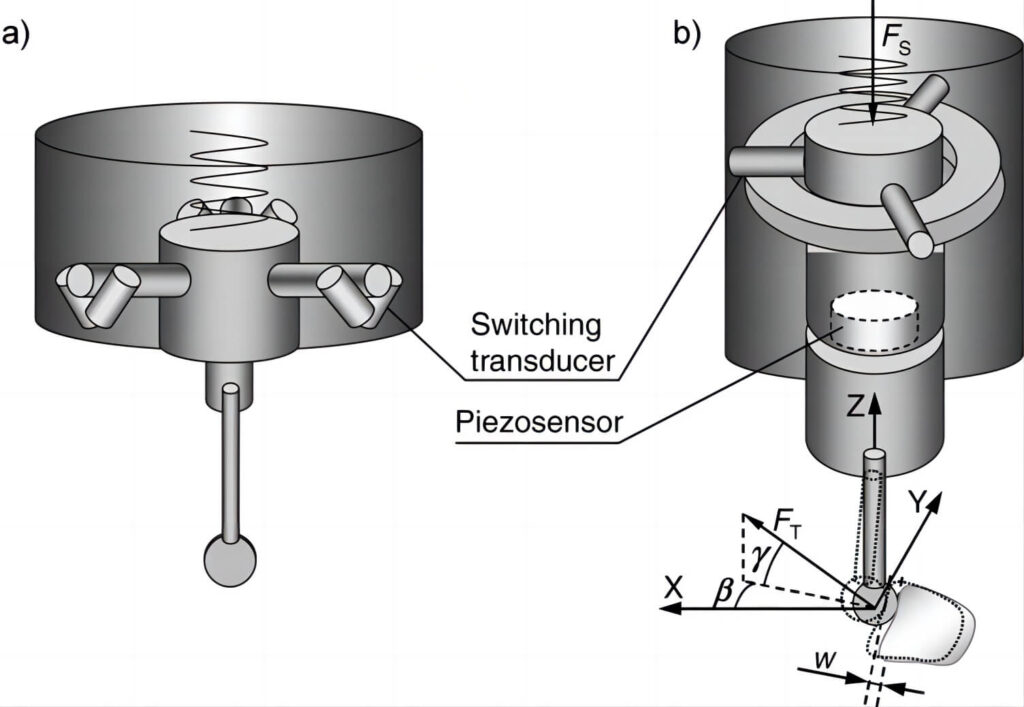

A pivotal moment came in 1972 with the invention of the trigger probe by the British company Renishaw. This ingenious design used a pulse signal to pinpoint the exact contact point between the probe and the workpiece. The trigger probe quickly became the industry standard.

Modern Advancements: Beyond the Trigger

While the trigger probe remains a cornerstone of CNC machining, the field hasn’t stagnated. Modern probes boast a range of functionalities, including:

- Scanning probes:Capture detailed profiles of complex shapes.

- Non-contact probes:Utilize various technologies like lasers for high-precision, touchless measurement.

- Automatic tool changers (ATCs):Allow for seamless switching between probes and machining tools within the CNC program.

These advancements have significantly improved the efficiency and accuracy of CNC operations.

The Future of Probe CNC Development

The future of Probe CNC development is bright. We can expect to see continued miniaturization for even more intricate measurements. Additionally, the integration of sensor technology could open doors for real-time monitoring and process control.

Conclusion

Probe CNC development is a testament to human ingenuity. From the early days of inductive micrometers to the sophisticated probes of today, these tools have revolutionized the world of CNC machining. As technology continues to evolve, we can only imagine the exciting possibilities that lie ahead for probe-assisted CNC operations.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.