Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

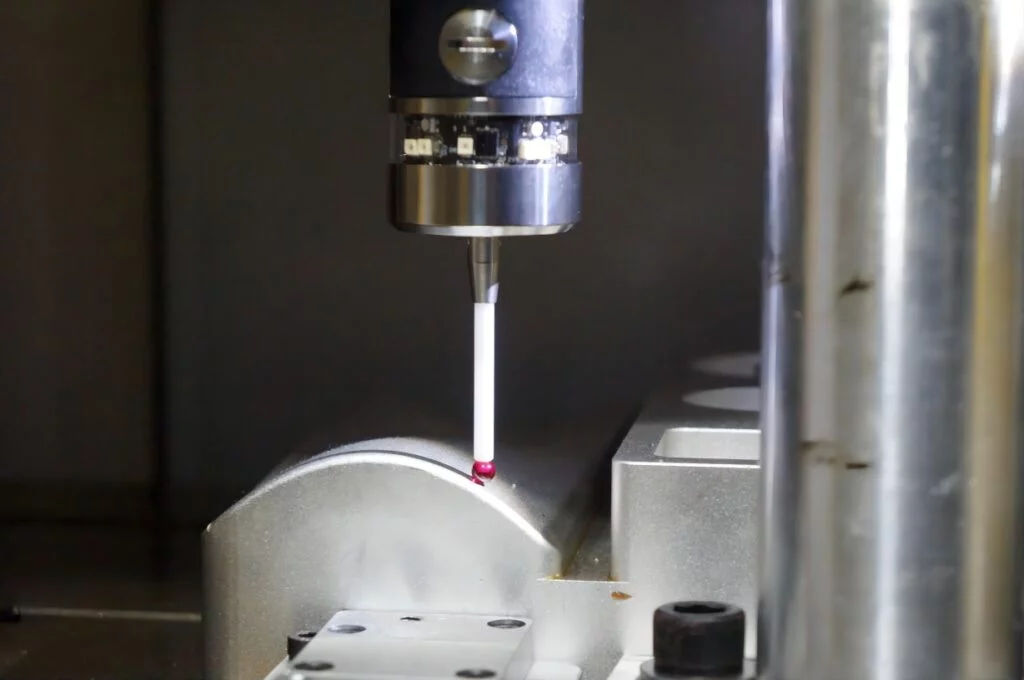

The world of CNC machines has dramatically transformed since their inception in the 1950s. Among the most pivotal advancements is the evolution of CNC touch sensors, which have significantly enhanced the precision, efficiency, and safety of CNC operations. This article explores the historical development of CNC touch sensors and how they have revolutionized the field over the years.

The Beginnings: Manual Inputs and Early CNC Touch Sensors

In the early days, CNC machines depended heavily on manual input for setup and operation. This manual process was labor-intensive and susceptible to human errors. The introduction of the first touch sensors in the 1970s marked a breakthrough, allowing operators to input data more swiftly and with greater accuracy. These initial sensors were rudimentary, utilizing mechanical switches to detect object presence.

Advancing Technology: The Rise of Capacitive Touch Sensors

With technological advancements, touch sensors evolved significantly in the 1980s with the development of capacitive touch sensors. These sensors leveraged the electrical properties of materials to sense objects, offering improved sensitivity and precision over their mechanical predecessors. Capacitive sensors became a popular choice for CNC machines due to their enhanced accuracy.

Precision and Durability: Optical Touch Sensors Take Over

The 1990s ushered in the era of optical touch sensors, which utilized light to detect objects. Optical sensors surpassed capacitive sensors in accuracy and durability, proving less vulnerable to wear and tear. Consequently, optical touch sensors quickly became the industry standard for CNC machines, offering superior performance and longevity.

A New Milestone: The Advent of Piezoelectric Touch Sensors

The early 2000s witnessed another leap forward with the development of piezoelectric touch sensors. These sensors harness the piezoelectric effect—where certain materials generate an electrical charge in response to mechanical stress. Piezoelectric sensors are exceptionally sensitive, capable of detecting minute pressure changes, making them ideal for applications requiring meticulous control in CNC machines.

Modern Innovations: Hybrid and Advanced Touch Sensors

Today’s CNC touch sensors are far more advanced compared to their early mechanical counterparts. Modern sensors often combine multiple technologies, such as capacitive and optical, to enhance sensitivity and accuracy. Some even incorporate sophisticated algorithms for faster and more efficient data processing, reflecting the significant technological strides made in recent years.

The Future Outlook: Multitouch and Beyond

Looking ahead, the future of CNC touch sensors is promising, with ongoing research aimed at further enhancing their capabilities. A key area of focus is the development of sensors that can detect multiple touch points simultaneously, enabling CNC machines to undertake more complex tasks with increased precision and efficiency.

Conclusion: The Ongoing Evolution of CNC Touch Sensors

The journey of CNC touch sensors from simple mechanical devices to highly sophisticated tools has been remarkable. Each technological advancement has brought about substantial improvements in the accuracy, efficiency, and safety of CNC operations. As technology continues to advance, we can anticipate even more groundbreaking developments in CNC touch sensor technology in the coming years.

CNC Touch Sensor FAQ

1.What is a CNC Touch Sensor?

A CNC touch sensor is a device used in computer numerical control (CNC) machines to detect and measure the position or presence of an object. These sensors are essential for automating and enhancing the accuracy of CNC operations, enabling machines to perform tasks such as precise positioning, tool alignment, and quality inspection.

2. How Do CNC Touch Sensors Work?

CNC touch sensors operate by detecting physical contact or proximity to an object. They employ various technologies to achieve this:

- Mechanical Touch Sensors:These use physical switches that activate when contact is made.

- Capacitive Touch Sensors:These detect objects based on changes in electrical capacitance when a conductive material is near the sensor.

- Optical Touch Sensors:These use light, such as lasers or infrared, to detect objects.

- Piezoelectric Touch Sensors:These generate an electrical charge in response to mechanical stress or pressure on certain materials.

Each technology offers different benefits in terms of sensitivity, accuracy, and application suitability.

3. What Are the Benefits of Using CNC Touch Sensors?

CNC touch sensors offer several advantages, including:

- Increased Accuracy:They ensure precise positioning and measurement, critical for high-quality machining.

- Enhanced Efficiency:Automating measurements and alignments reduces setup time and speeds up production.

- Improved Safety:Sensors can prevent collisions and reduce the risk of human error by providing accurate feedback on machine operations.

- Versatility:They can be used for various applications, from tool setting to quality control.

4. What Types of CNC Touch Sensors Are Available?

CNC touch sensors come in several types, each suited to different applications:

- Mechanical Touch Sensors:Basic sensors that use physical contact to detect objects.

- Capacitive Touch Sensors:Ideal for detecting non-metallic objects or liquids, using changes in capacitance.

- Optical Touch Sensors:Use light to detect objects, offering high accuracy and durability.

- Piezoelectric Touch Sensors:Highly sensitive sensors that detect minute pressure changes, excellent for detailed and precise measurements.

5. How Have CNC Touch Sensors Evolved Over Time?

CNC touch sensors have significantly evolved since their introduction:

- 1970s:Early mechanical sensors used for basic object detection.

- 1980s:Development of capacitive sensors increased sensitivity and accuracy.

- 1990s:Optical sensors became the standard, providing higher precision and durability.

- 2000s:Piezoelectric sensors introduced even greater sensitivity and were suitable for highly precise applications.

- Today:Modern sensors often combine multiple technologies and incorporate advanced algorithms for optimal performance.

6. What Are the Key Applications of CNC Touch Sensors?

CNC touch sensors are used in a variety of applications, including:

- Tool Setting:Ensuring tools are accurately positioned and aligned.

- Workpiece Measurement:Checking the dimensions and positioning of the workpiece before and during machining.

- Quality Control:Inspecting finished parts to ensure they meet specifications.

- Collision Avoidance:Preventing the machine from crashing into objects or itself.

7. How Do I Choose the Right CNC Touch Sensor for My Needs?

When selecting a CNC touch sensor, consider the following factors:

- Application Requirements:Determine what tasks the sensor will perform (e.g., tool setting, workpiece measurement).

- Sensitivity and Accuracy Needs:Choose a sensor that meets the precision required for your application.

- Durability and Environment:Consider the sensor’s ability to withstand the working conditions (e.g., exposure to dust, vibration, or temperature variations).

- Integration and Compatibility:Ensure the sensor is compatible with your CNC system and easy to integrate.

Consulting with a CNC expert or sensor manufacturer can also help in making the right choice.

8. What Are the Future Trends in CNC Touch Sensor Technology?

Future trends in CNC touch sensor technology include:

- Multi-touch Capabilities:Sensors that can detect multiple points of contact simultaneously, allowing for more complex operations.

- Enhanced Algorithms:Improved data processing algorithms for faster and more accurate feedback.

- Smarter Sensors:Integration with AI and machine learning to adapt and optimize performance in real-time.

- کوچک سازی:Smaller, more compact sensors for applications where space is limited.

9. How Do I Maintain and Care for My CNC Touch Sensor?

To maintain and ensure the longevity of your CNC touch sensor:

- Regular Cleaning:Keep the sensor and its surroundings clean to prevent dust and debris from affecting performance.

- Routine Calibration:Periodically calibrate the sensor to maintain accuracy.

- Check Connections:Ensure all electrical connections are secure and free from damage.

- Follow Manufacturer Guidelines:Adhere to the manufacturer’s maintenance recommendations and schedule.

Proper care and maintenance can significantly extend the life and performance of your CNC touch sensor.

10. Can CNC Touch Sensors Be Upgraded?

Yes, CNC touch sensors can often be upgraded. Upgrades can include:

- Software Updates:Enhancing the sensor’s capabilities and compatibility.

- Hardware Upgrades:Replacing outdated components with newer, more advanced ones.

- Technology Upgrades:Switching to a different type of sensor technology that better suits your needs.

Consult with your CNC machine provider or sensor manufacturer for available upgrade options.

11. Where Can I Purchase CNC Touch Sensors?

CNC touch sensors can be purchased from a variety of sources, including:

- CNC Equipment Manufacturers:Many CNC machine manufacturers also supply compatible touch sensors.

- Specialized Sensor Providers:Companies that specialize in sensor technology often offer a wide range of options.

- Industrial Suppliers:General industrial supply companies may also carry CNC touch sensors.

When purchasing, ensure that the sensor meets your specific requirements and is compatible with your CNC system.

کاترینا

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.