Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

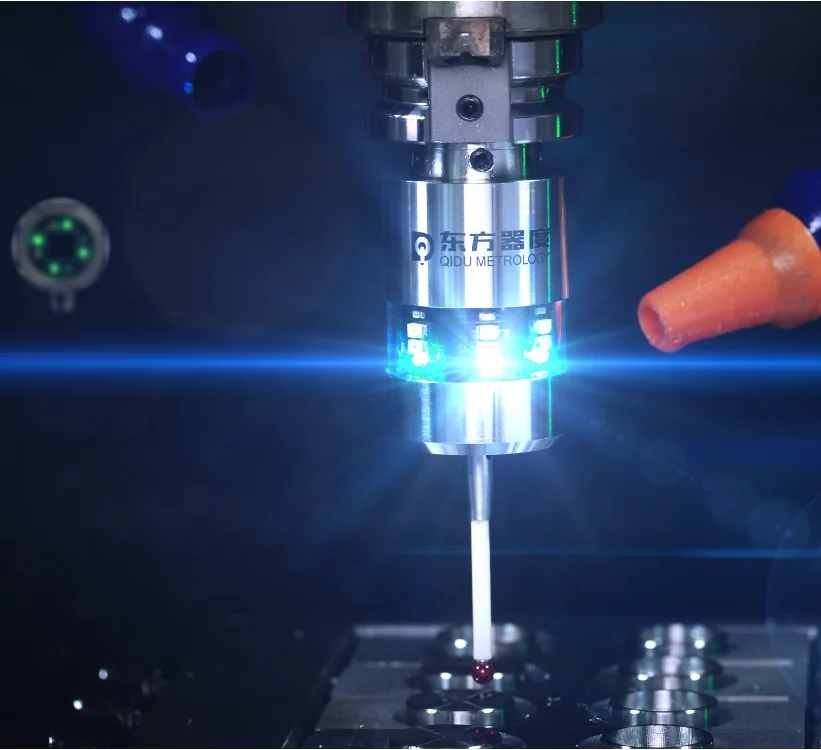

CNC Machine Probe Ensures Precision of Large Workpiece Machining

Customer’s Sharing about CNC Machine Probe Case

In the field of precision machining, large workpieces pose unique challenges due to their susceptibility to deformation during the machining process. Factors such as cutting forces and heat generated during machining can lead to dimensional inaccuracies, affecting the overall quality of the workpiece. To address these challenges, CNC machine probes have emerged as a valuable tool for ensuring the precise dimensions of large workpieces.

A recent case involving a customer utilizing a CNC machining center to fabricate a large workpiece highlights the effectiveness of CNC machine probes. The workpiece, prone to deformation due to the aforementioned factors, required precise dimensional control to meet stringent quality standards. To achieve this level of precision, the customer implemented a strategy that incorporated a CNC machine probe into the machining process.

Following the initial machining phase, the CNC machine probe was employed to measure critical points on the workpiece. This data was then used to adjust the machining parameters accordingly, effectively compensating for any deformation that may have occurred during the initial machining stage. By employing this iterative approach, the customer was able to achieve the desired dimensional accuracy for the large workpiece, ensuring that it met the required quality specifications.

The incorporation of a CNC machine probe into the machining process offered several advantages for the customer. Firstly, it streamlined the measurement process, eliminating the need for manual measurement techniques that were time-consuming and prone to errors. Secondly, the probe’s ability to provide real-time data enabled for dynamic adjustments to machining parameters, ensuring that the workpiece remained within the specified dimensional tolerances throughout the process.

The use of CNC machine probes in this case demonstrates their effectiveness in ensuring the precise machining of large workpieces. By providing a reliable and efficient method for measuring and correcting dimensional errors, CNC machine probes play a crucial role in maintaining the quality of large-scale machining projects. Their ability to streamline the measurement process and enable real-time adjustments makes them an invaluable tool for manufacturers seeking to achieve consistent precision in their machining operations.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.