Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

The Power of CNC Probing Software: Revolutionizing Efficiency and Accuracy in Machining

The world of CNC machining is constantly evolving, with advancements in technology continuously pushing the boundaries of precision and efficiency. One such innovation that has demonstrably transformed the industry is CNC probing software. This powerful tool empowers machinists to unlock a new level of control and automation, streamlining workflows and ensuring exceptional part quality.

Delving into the Depths of CNC Probing Software

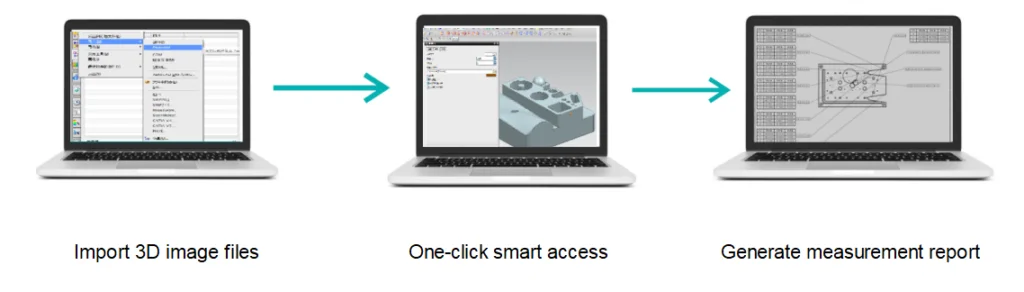

At its core, CNC probing software utilizes a specialized probe attached to the CNC machine tool. This probe acts as an extension of the cutting tool, allowing for highly accurate measurement and data collection directly on the machine. The software then interprets this data and translates it into actionable instructions for the CNC machine.

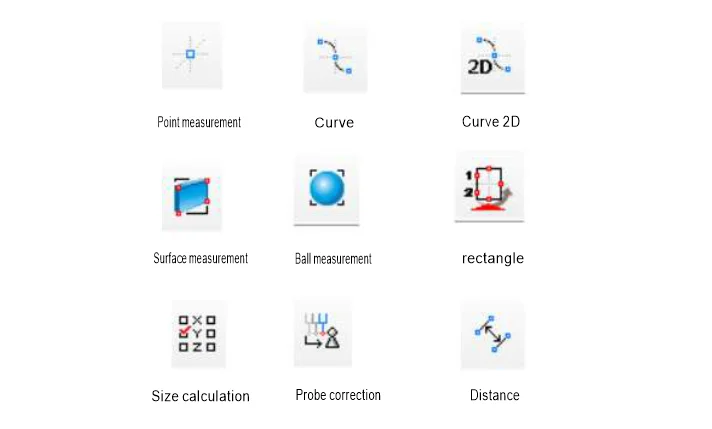

There are two primary categories of CNC probing software:

- Touch trigger probes:These probes activate upon physical contact with the workpiece, enabling functions like work offset determination, tool wear detection, and part verification.

- Scanning probes:These probes utilize various technologies, like lasers or touch scanning, to capture detailed data points across a surface. This allows for intricate tasks like automated path generation and complex profile measurement.

CNC probing software offers a comprehensive suite of functionalities, significantly impacting various aspects of the CNC machining process.

The Benefits of Embracing CNC Probing Software

Integrating CNC probing software into your workflow unlocks a multitude of advantages, including:

- Vylepšená přesnost:Probing eliminates human error during manual setup and measurement processes, leading to consistently precise machining results and minimized rework.

- Zvýšená účinnost:Automating repetitive tasks like work offsetting and tool wear detection frees up valuable operator time, allowing them to focus on more complex activities.

- Improved Quality Control:Probing enables real-time verification of part dimensions and tool wear, allowing for immediate adjustments and ensuring consistent quality throughout production runs.

- Reduced Set-up Times:Automated probing significantly reduces the time required for manual setup procedures, leading to faster production turnaround times.

- Minimized Scrap Rates:Probing identifies potential issues early in the machining process, preventing costly errors and material waste.

- Streamlined Workflows:CNC probing software integrates seamlessly with existing CAM systems, creating a more efficient and automated workflow from design to production.

These benefits translate into tangible improvements for your business, including increased profitability, enhanced customer satisfaction, and a competitive edge in the marketplace.

Applications of CNC Probing Software: A Realm of Possibilities

The versatility of CNC probing software makes it a valuable tool across a wide range of CNC machining applications. Here are some of the most common uses:

- Work Offset Setting:Probing automates the process of establishing the precise location of the workpiece within the machine’s coordinate system, ensuring accurate machining from the outset.

- Tool Length and Diameter Offset:Probing can automatically measure tool length and diameter changes due to wear, allowing for dynamic adjustments to maintain machining accuracy.

- Part Verification:Probing verifies the dimensional accuracy of machined features after each stage of the process, allowing for immediate corrective actions if necessary.

- In-Process Inspection:Probing enables real-time inspection of critical part dimensions throughout the machining process, catching potential issues early and preventing costly rework.

- Toolpath Verification:Certain probing systems can simulate toolpaths on the actual workpiece, ensuring collision avoidance and optimizing machining efficiency.

- Machine Tool Calibration:Probing can be used to calibrate machine axes and identify any potential mechanical issues before they impact production.

The potential applications of CNC probing software are constantly expanding, offering innovative solutions for an ever-growing range of machining challenges.

Navigating the Maze of CNC Probing Software Implementation

Integrating CNC probing software into your workflow requires careful consideration of several factors:

- How to Select the Right CNC Probing System:

- Machine Compatibility:Ensure the chosen probing system is compatible with your specific CNC machine tool and control system.

- Probing Technology:Evaluate your needs and select the most suitable probing technology (touch trigger or scanning) for your applications.

- Software Features:Consider the specific functionalities offered by different software packages and choose one that aligns with your current and future probing needs.

- Snadnost použití:Prioritize user-friendly software that minimizes training requirements and simplifies integration into existing workflows.

- Technická podpora:Select a vendor with a strong reputation for customer service and readily available technical support.

- Integrating CNC Probing Software into Workflows:

- Training:Provide comprehensive training for your operators on the proper use and maintenance of the probing system and software.

- Developing Probing Routines:Establish standardized probing routines that integrate seamlessly with your existing CAM programs and machining processes.

- Data Management:Develop a system for effectively managing the data collected through probing to ensure its accessibility for analysis and quality control purposes.

By carefully considering these factors and implementing a well-defined integration plan.

FAQ of Common Concerns

Integrating CNC probing software can raise various questions. Here, we address some of the most frequently asked ones:

- What are the initial investment costs associated with CNC probing software implementation?

The initial investment for CNC probing software can vary depending on several factors, including:

- The type of probing system (touch trigger or scanning)

- The capabilities and features of the software

- The size and complexity of your CNC machines

- The number of licenses required

While there is an upfront cost, the long-term benefits of CNC probing software often outweigh the initial investment. Increased efficiency, reduced scrap rates, and improved quality control can lead to significant cost savings over time.

- How does CNC probing software impact the overall production cycle time?

CNC probing software can significantly reduce setup times and automate repetitive tasks, leading to faster production turnaround. While probing itself may add a short amount of time to each machining cycle, the overall efficiency gains often translate into a net reduction in production time.

- What are the ongoing maintenance requirements for CNC probing systems?

The maintenance requirements for CNC probing systems are relatively minimal. Regular cleaning of the probe and calibration checks are crucial to ensure its accuracy. Additionally, staying updated on software updates and maintaining a service contract with your vendor can help optimize performance and address any potential issues.

- How does CNC probing software integrate with Industry 4.0 initiatives?

CNC probing software plays a vital role in Industry 4.0 initiatives by enabling real-time data collection and analysis. The data gathered through probing can be used for various purposes, such as:

- Optimizing machining processes:Analyzing probing data can identify areas for improvement in toolpathing, cutting parameters, and overall machining efficiency.

- Prediktivní údržba:By monitoring tool wear and machine performance through probing data, you can implement preventative maintenance strategies to avoid unplanned downtime.

- Process automation:Probing data can be integrated with other Industry 4.0 technologies to automate various aspects of the manufacturing process, creating a self-optimizing and highly efficient production environment.

- What are the safety considerations when implementing CNC probing software?

Safety is paramount in any machining environment. When implementing CNC probing software, it’s crucial to adhere to the following safety guidelines:

- Proper training:All personnel operating the CNC machine with probing capabilities must receive thorough training on safe probing practices.

- Collision avoidance:Ensure your probing routines are carefully programmed to avoid collisions between the probe and the workpiece or other machine elements.

- Machine guarding:Maintain proper machine guarding around the probing system to prevent operator injury.

- Regular maintenance:Regularly inspect and maintain the probing system to ensure its functionality and prevent malfunctions.

By following these safety protocols, you can ensure the safe and effective utilization of CNC probing software in your machining operations.

Závěr

CNC probing software represents a transformative technology in the world of CNC machining. By offering unparalleled precision, efficiency, and quality control, it empowers businesses to achieve a significant competitive edge. If you’re looking to streamline your workflows, minimize errors, and elevate your manufacturing capabilities, integrating CNC probing software into your operations is a strategic investment with demonstrably positive outcomes.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.