Email: [email protected] Phone: (+86) 134 1323 8643

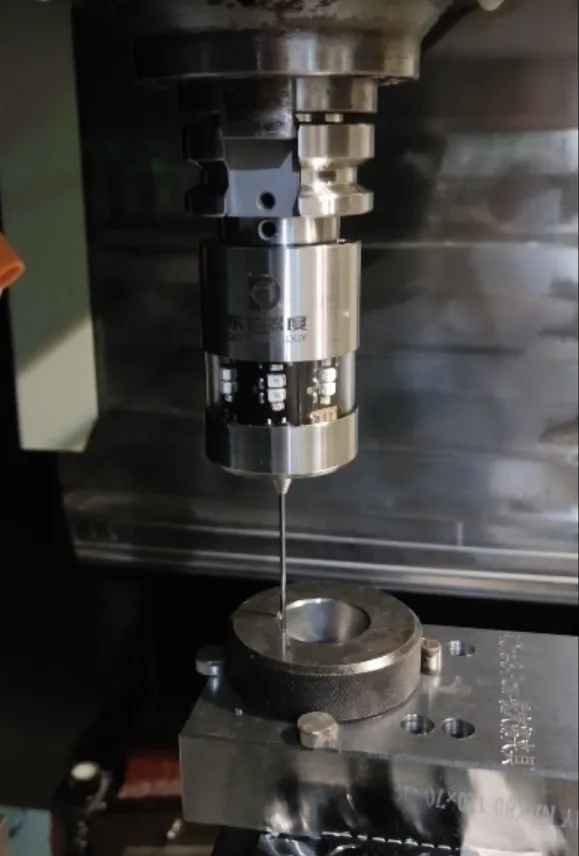

How CNC Digitizing Touch Probes Transform Precision Machining

The Evolution of Precision Machining

Precision machining is undergoing a transformation thanks to the revolutionary impact of CNC digitizing touch probes, introducing a more precise and efficient approach to measuring and setting up workpieces. These probes employ a precision sensor to gauge the workpiece’s surface, and the gathered data is then utilized to generate a digital representation of the part. Subsequently, this model serves as the basis for creating a CNC program that precisely machines the part according to specifications.

CNC digitizing touch probes boast several advantages over conventional measurement techniques, including:

- Accuracy: Touch probes can achieve measurements with an accuracy of 0.0001 inches, a significant improvement over traditional methods like dial indicators or calipers.

- Efficiency: Touch probes excel at swiftly and effortlessly measuring intricate parts, translating to time and cost savings.

- Versatility: These probes can be applied to measure a diverse array of parts, including those with intricate shapes or features.

Open Source CNC Probing

The emergence of open-source CNC probing software has democratized access to touch probes, enabling hobbyists and small businesses to leverage their benefits. Typically available for free, this software can be tailored to suit the user’s specific requirements.

One popular open-source CNC probing software is TouchDRO, accessible at this URL: TouchDRO. Noteworthy features of TouchDRO include:

- Graphical User Interface: TouchDRO’s user-friendly graphical interface facilitates easy use, even for beginners.

- Various Measurement Modes: TouchDRO incorporates diverse measurement modes such as point-to-point, linear, and circular.

- CNC Program Creation: Users can employ TouchDRO to generate CNC programs that precisely machine parts to meet specifications.

CNC Touch Probe Wiring

The wiring process for a CNC touch probe is relatively straightforward. Typically, the probe is connected to a breakout board, which, in turn, links to the CNC machine’s controller. The breakout board not only provides a convenient connection between the probe and the controller but also supplies power to the probe.

The following steps outline the basic procedure for wiring a CNC touch probe:

- Connect the probe to the breakout board.

- Link the breakout board to the CNC machine’s controller.

- Power on both the CNC machine and the probe.

- Configure the software to integrate the probe.

Once the probe is properly wired and configured, it becomes a valuable tool for measuring parts and creating CNC programs.

In Conclusion

CNC digitizing touch probes play a pivotal role in enhancing precision machining, offering advantages such as heightened accuracy, efficiency, and versatility over traditional measurement methods. The advent of open-source CNC probing software has extended these benefits to hobbyists and small businesses. Wiring a CNC touch probe is a straightforward process, and with the right tools and knowledge, anyone can utilize a touch probe to elevate the accuracy and efficiency of their CNC machining operations.