Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

Touch Probe for CNC Machines is A Crucial Tool

Enhancing Precision in CNC Machining

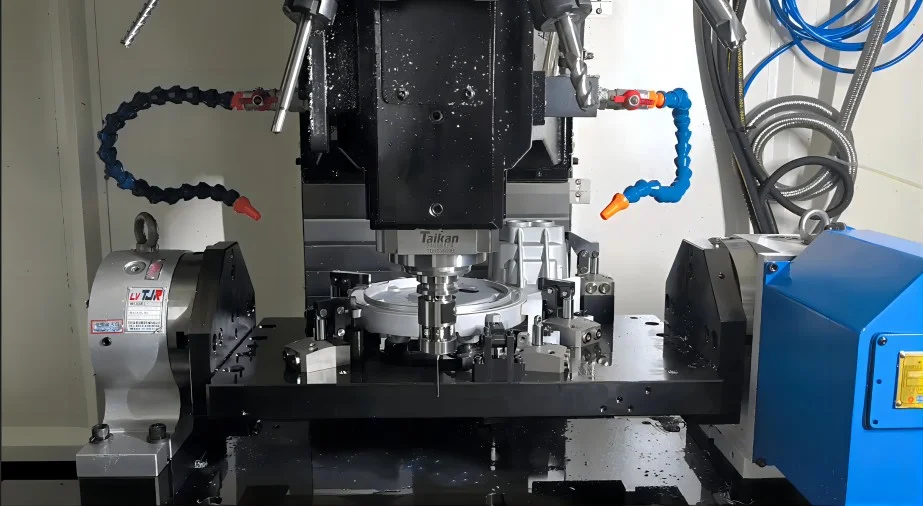

CNC machines have transformed the landscape of manufacturing, offering unparalleled precision and efficiency in tasks ranging from cutting to milling. However, achieving such accuracy demands the utilization of sophisticated tools, among which touch probe for CNC machines stands out as indispensable aids.

Unveiling the Role of Touch Probe for CNC Machines

A touch probe for CNC machines, a handheld device equipped with sensors, serves as the linchpin for precise positioning and measurement in CNC machines. By detecting the tool and workpiece’s presence, it furnishes crucial data for the machine to execute tasks with utmost accuracy.

Precision Positioning with Touch Probes

The primary function of touch probes lies in facilitating the accurate alignment of the tool with the workpiece, particularly crucial for intricate designs where precision is paramount. With this tool, CNC machines can adeptly adjust movements, ensuring meticulous execution even with complex geometries.

Measuring with Unrivaled Accuracy

Beyond positioning, touch probes excel in measuring the distance between the tool and the workpiece, a critical task when dealing with challenging materials or irregular shapes. This capability ensures consistent depth and thickness, enhancing the quality of the final product.

Detecting Imperfections for Perfection

An added advantage of touch probes is their ability to detect surface irregularities like burrs or dents on the workpiece. Armed with this information, CNC machines can adapt their settings to mitigate imperfections, guaranteeing superior product quality.

Embracing Touch Probes for Manufacturing Excellence

Touch probes for CNC Machines have become indispensable companions, furnishing vital data for precise positioning, measurement, and surface monitoring. Integrating touch probes into manufacturing workflows elevates precision, efficiency, and overall product quality, underscoring their pivotal role in modern manufacturing’s success and growth.

Exploring the Diversity of Touch Probes

Touch probes for CNC machines are indispensable allies in the realm of lathes, ensuring precision and efficiency in operations. These devices act as liaisons between the workpiece and the machine, furnishing vital data for accurate positioning and measurement. Let’s delve into the diverse array of touch probes available for CNC machines, shedding light on their distinctive features and applications.

Contact Probes: A Common Choice

Contact probes stand as the cornerstone of touch probe technology, frequently employed for tasks like part inspection and tool setting. Comprising a stylus that physically engages with the workpiece’s surface, these probes deliver essential data to the CNC machine. The stylus material varies, ranging from diamond to tungsten carbide or plastic, catering to specific application needs. Contact probes boast affordability and ease of maintenance, rendering them a favored option among CNC users.

Non-contact Probes: Pioneers of Precision

In contrast, non-contact probes harness electromagnetic or optical principles to gauge the distance between the probe and the workpiece sans physical interaction. Ideal for delicate or damage-prone surfaces, these probes eliminate the risk of surface abrasions, making them invaluable in high-speed machining scenarios. Their non-invasive nature expedites operations by circumventing the need for physical contact.

Scanning Probes: Elevating Precision to New Heights

Scanning probes represent the zenith of touch probe innovation, offering exhaustive analyses of the workpiece’s surface. Employing sensors and software, these probes generate intricate 3D maps of the workpiece, facilitating tasks such as reverse engineering, surface inspection, and tool path optimization. Industries demanding meticulous measurements and detailed surface insights, such as aerospace and medical manufacturing, find scanning probes indispensable for their operations.

Choosing the Right Touch Probe for CNC Machines

When selecting a touch probe for CNC machines, meticulous consideration of application-specific requirements is paramount. Factors like workpiece material, size, complexity, desired precision, and speed dictate the ideal probe choice. Compatibility with your CNC machine’s control system and software is equally crucial. By discerningly evaluating these factors, you ensure optimal performance and efficiency from your CNC machine.

Maximizing CNC Potential with Touch Probes

In the intricate dance of CNC machining, touch probes emerge as silent conductors, orchestrating precise movements and measurements. A comprehensive understanding of touch probe for CNC machines varieties empowers you to make informed decisions, aligning the probe’s capabilities with your application needs. Armed with the right touch probe, your CNC machine unlocks its full potential, fostering enhanced product quality and heightened productivity.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.