Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

The manufacturing industry is undergoing a period of significant transformation. Automation, digitalization, and an increasing focus on precision and efficiency are driving this change. Among the key technologies shaping this evolution are machine tool probes. These innovative devices are playing a vital role in enhancing accuracy, streamlining workflows, and boosting productivity across various manufacturing sectors.

Introduction of Machine Tool Probes

A. Overview of Machine Tool Probes in Manufacturing

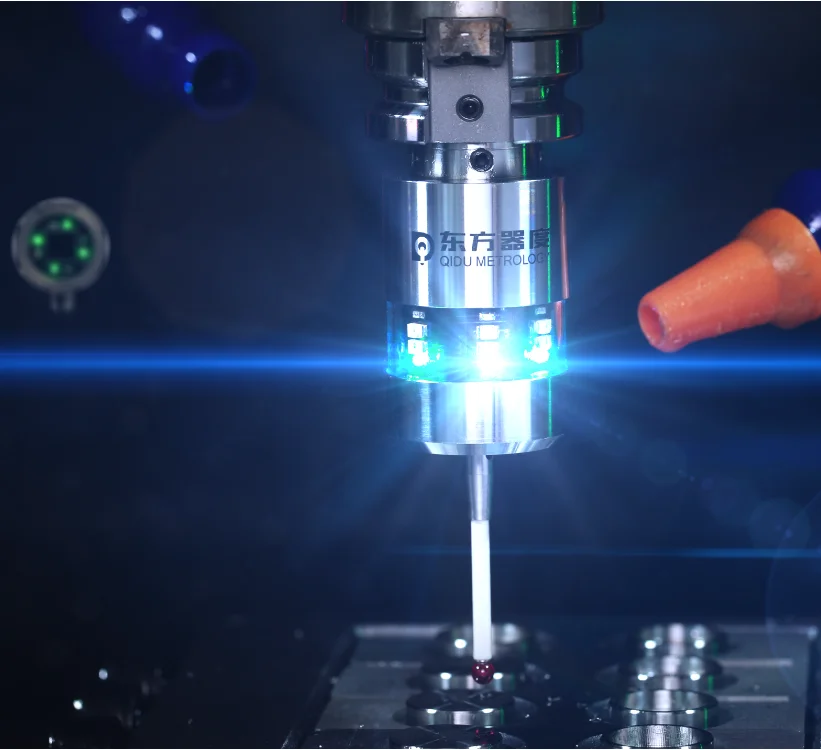

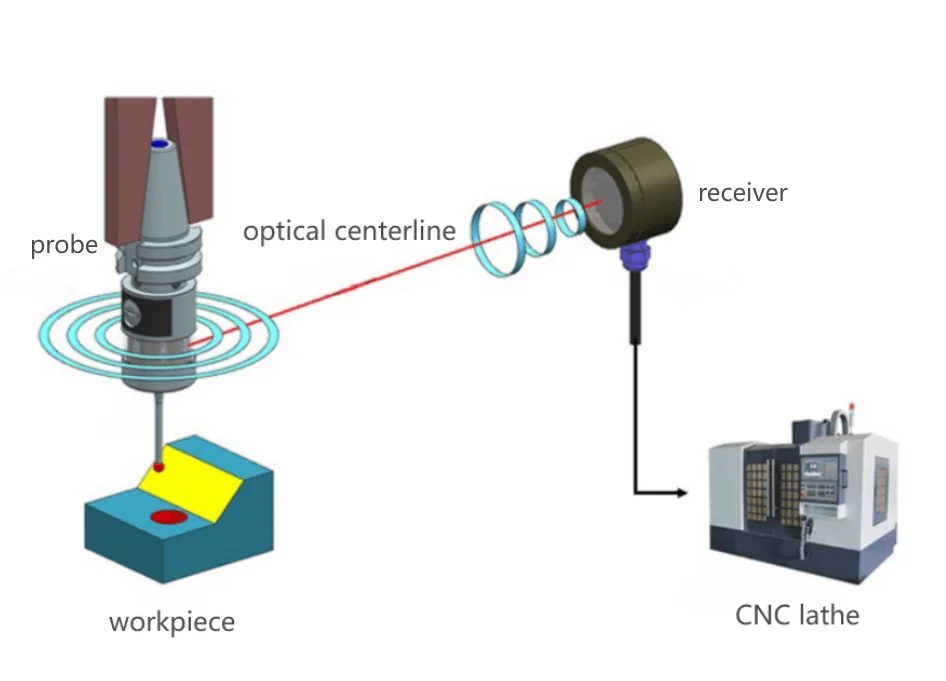

Machine tool probes are essentially specialized sensors used in conjunction with CNC (Computer Numerical Control) machines and machining centers. They act as an extension of the machine tool itself, allowing for automated measurement and data collection of workpieces and cutting tools. These probes can be triggered through the CNC program, enabling the machine to gather information about the position, size, and orientation of a workpiece or tool.

B. Importance of Machine Tool Probes in Industry Transformation

The significance of machine tool probes lies in their ability to address critical challenges faced by modern manufacturing. Here’s how they contribute to industry transformation:

- উন্নত নির্ভুলতা:Probes ensure accurate workpiece setup and tool positioning, minimizing errors and improving overall part quality.

- কম সেটআপ সময়:Automated measurement eliminates the need for manual intervention, significantly reducing setup times and increasing machine utilization.

- উন্নত প্রক্রিয়া নিয়ন্ত্রণ:In-process inspection with probes allows for real-time monitoring of parts, enabling adjustments to be made during production for consistent quality.

- Reduced Scrap Rate:Early detection of errors and tool wear with probes prevents the creation of defective parts, minimizing scrap and rework costs.

- Increased Productivity:Faster setup times, automated processes, and fewer errors all contribute to significant gains in overall manufacturing productivity.

The Evolution of Technology

A. Historical Development of Machine Tool Probes

The concept of using probes for machine tool applications dates back to the early 20th century. However, early models were primarily mechanical in design, offering limited functionality and reliability. The development of electronics and sensor technology in the latter half of the century paved the way for more sophisticated probes.

The 1970s and 1980s saw the introduction of solid-state probes with improved accuracy and repeatability. The advent of CNC machines further accelerated the adoption of probes, as they became seamlessly integrated into the machining process.

B. Integration of Advanced Technologies with Machine Tool Probes

Modern machine tool probes are marvels of engineering, incorporating various advanced technologies:

- Touch Trigger Systems:These probes utilize a spring-loaded mechanism that triggers a signal upon contact with the workpiece or tool.

- Non-Contact Sensors:Technologies like laser triangulation and eddy current provide high-precision, non-contact measurement capabilities.

- Wireless Communication:Advanced probes can transmit data wirelessly to the CNC controller, eliminating the need for cumbersome cables and improving flexibility.

- সফটওয়্যার ইন্টিগ্রেশন:Modern probing software allows for sophisticated programming of measurement routines and data analysis, further enhancing process control.

Enhancing Precision and Efficiency

A. Role of Machine Tool Probes in Improving Accuracy

Machine tool probes contribute to accuracy in several ways:

- Automated Measurement:Eliminates human error associated with manual setup and inspection.

- High Repeatability:Provides consistent and reliable measurement results every time.

- Improved Workpiece Positioning:Ensures accurate positioning of parts within the machine tool, leading to tighter tolerances and better part quality.

- টুল পরিধান সনাক্তকরণ:Early detection of tool wear allows for preventive maintenance and prevents machining errors due to worn tools.

B. Increasing Productivity through Automated Processes

Probes significantly boost productivity by streamlining various aspects of the manufacturing process:

- দ্রুত সেটআপ সময়:Automated probing eliminates the need for manual setup procedures, saving valuable production time.

- Reduced Downtime:Early detection of tool wear and potential part defects minimizes machine downtime for repairs and rework.

- Unmanned Machining:Enables unattended operation of machines during probing cycles, improving machine utilization and overall throughput.

- Improved Process Consistency:Consistent and accurate measurements lead to fewer production errors and a smoother workflow.

Innovation and Future Trends

A. Emerging Technologies in Machine Tool Probes

The relentless pace of technological advancement continues to shape the future of machine tool probes. Here are some exciting developments to watch:

- Sensor Fusion:Integration of multiple sensor technologies (e.g., vision systems with touch triggering) for even more comprehensive and versatile probing capabilities.

- On-Machine Measurement & Analysis:Advanced probes with built-in data processing and analysis functionalities for real-time decision making.

- Self-Learning and Adaptive Systems:Probes with the ability to learn from past data and adapt probing routines for optimized efficiency.

B. Predictions for the Future of Manufacturing with Machine Tool Probes

The future of manufacturing with machine tool probes promises exciting possibilities:

- Greater Automation:Advanced probes will enable even higher levels of automation in machining processes, leading to lights-out manufacturing capabilities.

Case Studies and Success Stories

A. Real-world Examples of Companies Benefiting from Machine Tool Probes

Machine tool probes are delivering tangible benefits across a wide range of industries. Here are a few examples:

- Aerospace Manufacturing:A leading aerospace manufacturer implemented in-process probing with laser technology to ensure precise positioning of critical components in aircraft engines. This resulted in a significant reduction in scrap rates and improved overall part quality.

- মোটরগাড়ি শিল্প:An automotive parts supplier utilizes touch trigger probes for automated tool setting and workpiece verification. This ensures consistent tool lengths and part dimensions, leading to increased production efficiency and reduced rework costs.

- মেডিকেল ডিভাইস উত্পাদন:A manufacturer of surgical instruments uses non-contact probes for high-precision measurement of complex geometries. This allows for close adherence to tight tolerances and ensures the functionality and reliability of these critical medical devices.

B. Impact of Machine Tool Probes on Various Industries

The benefits of machine tool probes extend far beyond these specific examples. They are making a positive impact in various industries, including:

- Mold & Die Making:Probes ensure accurate alignment of mold components, leading to the production of high-quality molds with minimal rework.

- ইলেকট্রনিক্স উত্পাদন:Automated probing facilitates precise component placement on printed circuit boards, enhancing product reliability and performance.

- Job Shops:The flexibility and ease of use of probes make them ideal for small batch production runs, allowing for efficient setup and consistent quality.

People Also Ask about Machine Tool Probes

- How do Machine Tool Probes improve manufacturing processes?

Machine tool probes improve manufacturing processes in several ways:

- Enhanced precisionthrough automated measurement and tool wear detection.

- Increased efficiencywith faster setup times, reduced downtime, and unmanned machining capabilities.

- Improved process controlthrough real-time monitoring and data analysis.

- Reduced scrap rateby preventing errors and identifying potential issues early.

- Greater consistencyin part quality due to accurate measurements and automated processes.

- What are the benefits of implementing Machine Tool Probes in production?

The benefits of implementing machine tool probes in production include:

- Reduced production coststhrough minimized scrap, rework, and downtime.

- Increased productivitywith faster setups, higher machine utilization, and smoother workflows.

- Enhanced product qualityby ensuring consistent part dimensions and adherence to tolerances.

- Improved process controlfor real-time monitoring and adjustments to maintain quality.

- Greater flexibilityfor various machining applications and batch sizes.

- What are the challenges of integrating Machine Tool Probes into existing systems?

Some challenges associated with integrating machine tool probes into existing systems include:

- Initial investment costof purchasing and installing the probing system.

- Programming complexityfor developing probing routines within the CNC program.

- Machine compatibilityensuring the probe is compatible with the specific CNC machine and controller.

- Operator trainingproviding adequate training for operators on the use and benefits of probes.

- How does the future look for Machine Tool Probes in manufacturing?

The future of machine tool probes is bright. With advancements in sensor technology, data analytics, and self-learning capabilities, probes will play an even greater role in:

- Further automationof machining processes, leading to lights-out manufacturing.

- Enhanced process controlwith real-time decision making based on in-situ data analysis.

- Improved overall efficiencythrough optimized workflows and reduced production waste.

- Greater flexibilityfor adapting to changing production demands and complex geometries.

By harnessing the power of machine tool probes, manufacturers can unlock a new era of precision, efficiency, and agility in the ever-evolving landscape of modern manufacturing.

ক্যাটরিনা

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.