Email: katrina@qidumetro.com Phone: (+86) 134 1323 8643

Ever wished your CNC machine could automatically find its reference point or verify workpiece dimensions? Well, a touch probe can make that a reality. This guide will equip you with the knowledge to set up and utilize a touch probe, unlocking a new level of efficiency and precision in your CNC operations.

Introduction to Touch Probe for CNC Machine

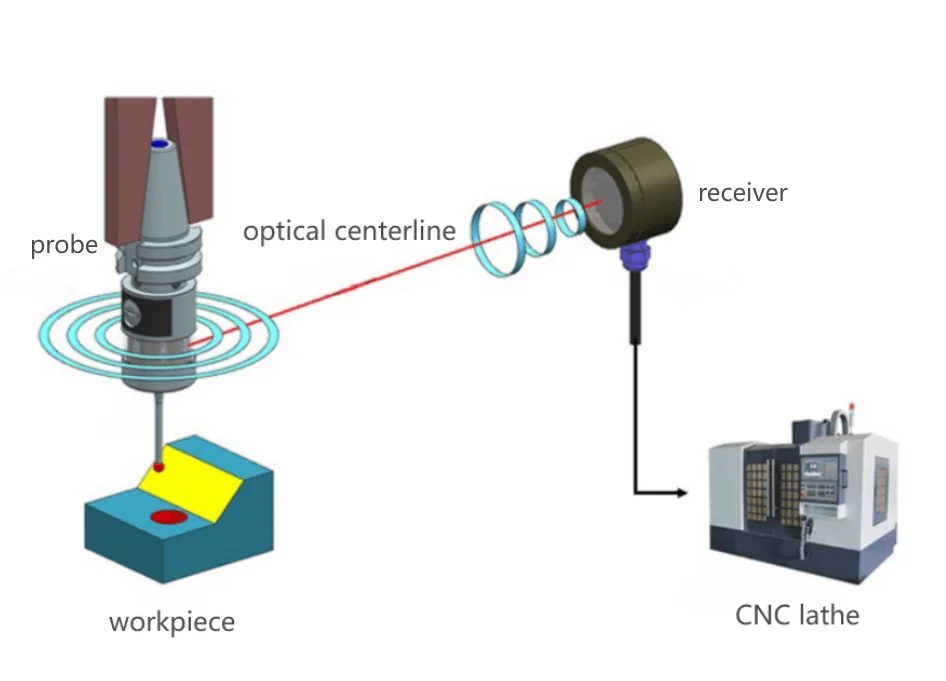

A touch probe is a sensory tool for CNC machines. It features a spring-loaded stylus that makes contact with the workpiece or a conductive surface. This contact triggers a signal to the CNC controller, allowing for automated functions like:

- Workpiece Setup:The probe can locate the X, Y, and Z zero points of the workpiece, ensuring accurate tool positioning for machining.

- Tool Length Offset and Wear Compensation:By touching a reference point, the probe can automatically determine and set the tool length offset, compensating for wear on the cutting tool.

- Workpiece Dimension Verification:The probe can measure the thickness or specific dimensions of the workpiece, eliminating manual measurement errors.

- In-Process Inspection:The probe can be used during machining to verify tool path accuracy and identify potential errors.

Understanding the Basics of Touch Probe for CNC Machine

Here’s a breakdown of the key components of a touch probe:

- Stylus:The tip of the probe, typically made from a conductive material like spring steel. It makes contact with the workpiece or surface.

- Spring Mechanism:Applies a constant, gentle pressure on the stylus, ensuring consistent detection upon contact.

- Switch/Sensor:Detects the deflection of the stylus when it touches a conductive surface, sending a signal to the CNC controller.

- Housing:Protects the internal components and provides a mounting point for the probe on the CNC machine.

- Cable:Connects the probe to the CNC controller for signal transmission.

Touch probes come in various types, each suited for specific applications:

- Spring-Loaded Mechanical Probe:Simple and reliable, ideal for general workpiece setup and tool offset.

- Touch-Triggered Electronic Probe:Offers higher accuracy with adjustable sensitivity for delicate applications.

- Inductive Probe:Detects changes in magnetic field, suitable for non-conductive materials like wood and plastics.

- Laser Probe:Uses a laser beam for non-contact, high-precision measurement.

Preparing for Setup

Before diving into the installation process, ensure you have the necessary tools and equipment:

- Touch Probe:Choose a probe compatible with your CNC machine and control system.

- Mounting Hardware:Screws, brackets, or adapters for attaching the probe to the CNC machine.

- Multimeter (Optional):For verifying electrical connections in some probe models.

- Basic Hand Tools:Screwdrivers, wrenches, and Allen keys as needed for installation.

- CNC Machine Manual:Refer to the manual for specific instructions and safety precautions.

Choosing the Right Touch Probe for Your CNC Machine

Consider these factors when selecting a touch probe:

- ተኳኋኝነትEnsure the probe is compatible with your CNC machine’s control system and available input ports.

- Functionality:Choose a probe with features that meet your application needs. Do you need basic setup functionality or advanced features like tool wear compensation?

- Workpiece Material:For non-conductive materials, consider inductive or laser probes.

- ትክክለኛነት እና ተደጋጋሚነት;Select a probe with the desired level of precision for your projects.

- Ease of Use and Maintenance:Opt for a probe with a user-friendly design and readily available replacement parts.

Installation Process

Mounting the Touch Probe on Your CNC Machine

- Refer to the CNC machine manual and probe instructionsfor specific mounting details.

- Identify a suitable mounting locationon the CNC machine toolholder or spindle. It should provide a clear path for the probe’s movement and avoid interference with the cutting tool or workpiece.

- Secure the probe using the provided mounting hardware.Ensure a rigid and stable connection.

- Adjust the probe’s orientationif necessary. The stylus tip should be positioned perpendicular to the workpiece surface for accurate contact.

Connecting the Touch Probe to the CNC Controller

- Locate the appropriate input porton the CNC controller as per the manual. This might be a dedicated touch probe port, a digital input port, or a relay connection.

- Connect the probe cableto the designated port on the controller. Match the wire colors to the corresponding terminals if applicable.

- Use a multimeter (if required)to verify proper connection between the probe and controller based on the probe’s wiring diagram.

Calibration and Configuration

Calibrating the Touch Probe for CNC Machine

Calibration ensures the probe’s accuracy by establishing the reference point between the stylus tip and the probe body.

- Prepare a calibration block:This is a flat, smooth surface of known thickness made from a material compatible with your probe type (conductive for mechanical/electronic probes). Steel or aluminum are commonly used.

- Install a tool with a known length(like a ball nose end mill) into the CNC machine spindle.

- Access the calibration menuin your CNC software. The specific steps may vary depending on your software. Consult the software manual for detailed instructions.

- Command the probe to touch the surfaceof the calibration block. The software will typically prompt you to jog the machine axes until the probe triggers a signal.

- Input the known thicknessof the calibration block into the software.

- The software will calculate and set the tool length offsetbased on the probe’s trigger point and the known thickness. This offset value accounts for the distance between the probe’s stylus tip and the machine spindle.

Configuring CNC Software for Touch Probe Integration

Once the probe is calibrated, configure your CNC software to utilize its functionalities. This may involve:

- Defining Probe Inputs:Specify which input port on the CNC controller is connected to the touch probe.

- Creating Macro Functions:Develop macros (automated routines) within the software to utilize the probe for specific tasks like workpiece setup, tool offset, or in-process inspection.

- Setting Probe Activation/Deactivation:Define how the probe will be activated and deactivated during CNC operations (e.g., through M-codes or dedicated software buttons).

Practical Applications

Using the Touch Probe for Workpiece Setup

With a touch probe, setting up your workpiece becomes efficient and precise:

- Jog the machine axesto bring the probe stylus near the workpiece surface.

- Activate the touch probe functionin your CNC software.

- The machine will automatically movethe probe until it touches the workpiece, registering the X, Y, and Z coordinates as the zero point reference.

- This established reference pointallows for accurate toolpath execution and eliminates manual zero setting errors.

Advanced Applications of Touch Probe for CNC Machine

Touch probes unlock a wider range of functionalities beyond basic setup:

- Tool Length and Wear Compensation:The probe can repeatedly touch a reference point to determine and update the tool length offset, automatically accounting for tool wear during machining.

- Workpiece Dimension Verification:The probe can be used to measure the thickness or specific dimensions of the workpiece at various points, verifying its conformity to the design specifications.

- In-Process Inspection:By strategically incorporating probe touches within the toolpath, you can verify if the cutting tool is following the programmed path and identify potential machining errors before they become significant.

- Automatic Tool Change (ATC) with Tool Pre-setting:In CNC machines with ATC systems, the probe can be used to pre-set tool lengths offline on a separate fixture. This eliminates the need for manual tool length setting during tool changes, saving time and improving workflow efficiency.

Troubleshooting and Maintenance

Common Issues and How to Fix Them

- Probe Failure to Trigger:Check the probe connection, ensure the probe is properly calibrated, and verify the software settings for probe activation.

- Inaccurate Measurements:Recalibrate the probe using a known reference block. Clean the stylus tip and ensure there’s no debris affecting contact.

- Software Errors:Refer to your CNC software manual for troubleshooting specific error codes related to the touch probe.

Regular Maintenance for Touch Probes

- Clean the stylus tipregularly to remove dust, debris, or built-up material that can affect contact accuracy.

- Inspect the probe housing and cablefor any damage that might compromise functionality.

- Periodically recalibrate the probeto maintain its accuracy, especially after extended use or if the stylus tip is replaced.

Maximizing Efficiency

Tips for Optimizing CNC Operations with Touch Probe

- Develop standardized touch probe macrosfor frequently used tasks like workpiece setup and tool offset to streamline workflow.

- Utilize the probe for in-process inspectionto catch errors early and minimize rework.

- Explore advanced functionalitieslike tool pre-setting for ATC systems to maximize machine uptime.

- Invest in high-quality touch probeswith robust features and reliable performance for long-term benefits.

Case Studies: Success Stories of Touch Probe Implementation

Many CNC machine users have reported significant improvements in efficiency and accuracy after implementing touch probes. Here are some potential benefits:

- የተቀነሰ የማዋቀር ጊዜ፡-Automating workpiece setup with the probe can save significant time compared to manual methods.

- የተሻሻለ ክፍል ጥራት፡-Automatic tool offset and in-process inspection with the probe minimize errors and ensure consistent part quality.

ማጠቃለያ

Touch probes offer a powerful upgrade for CNC machining operations. By following this step-by-step guide, you can set up and utilize a touch probe to unlock a new level of efficiency, precision, and automation in your workshop. Remember these key points:

- Choose the right touch probe based on compatibility, functionality, and your specific needs.

- Carefully follow the calibration and configuration steps to ensure accurate measurements.

- Explore the various applications of the touch probe for workpiece setup, tool management, in-process inspection, and more.

- Maintain your touch probe with regular cleaning and calibration to guarantee optimal performance.

By integrating a touch probe into your CNC workflow, you can experience significant improvements in production speed, part quality, and overall machine utilization.

People Also Ask

1.What is the main function of a touch probe in CNC machining?

Touch probes act as sensory tools for CNC machines. They allow for automated functions like workpiece setup, tool length offset, workpiece dimension verification, and in-process inspection.

2.How do I choose the right touch probe for my CNC machine?

Consider compatibility with your CNC control system, desired functionalities, workpiece material, accuracy requirements, and ease of use when selecting a touch probe.

3.What are the common issues faced during touch probe setup?

Probe connection issues, inaccurate measurements due to calibration errors or dirty stylus tips, and software errors related to probe activation are common challenges.

4.How often should I calibrate my touch probe?

Regular calibration is recommended, especially after extended use or replacing the stylus tip.

5.Can a touch probe be used for both setup and inspection?

Yes, touch probes offer a wide range of functionalities. They can be used for initial workpiece setup, tool offset, and in-process inspection throughout the machining process.

ካትሪና

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.