Email: [email protected] Phone: (+86) 134 1323 8643

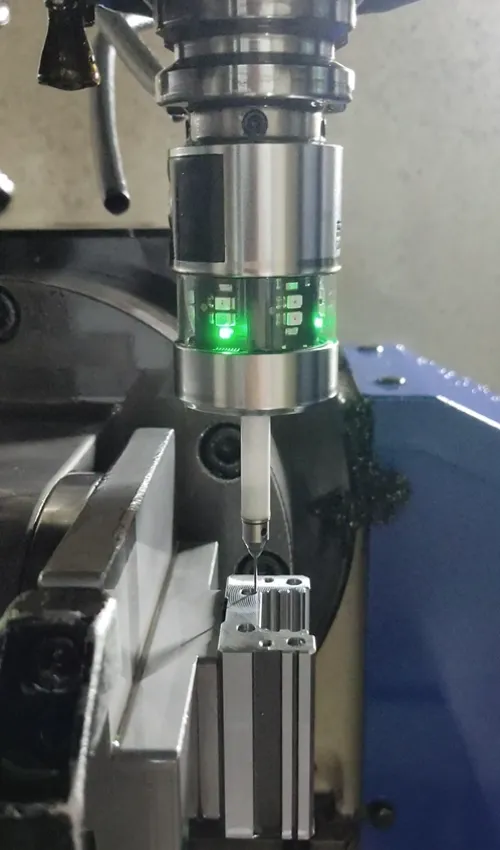

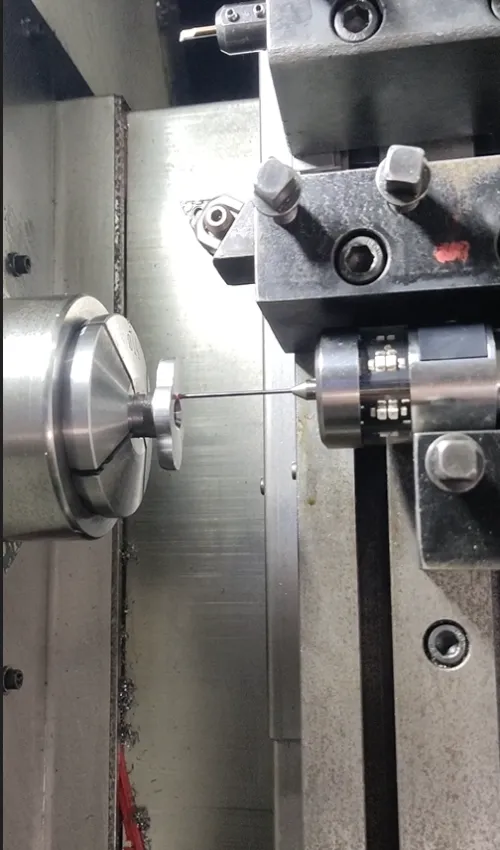

Tool Height Setter DTS100

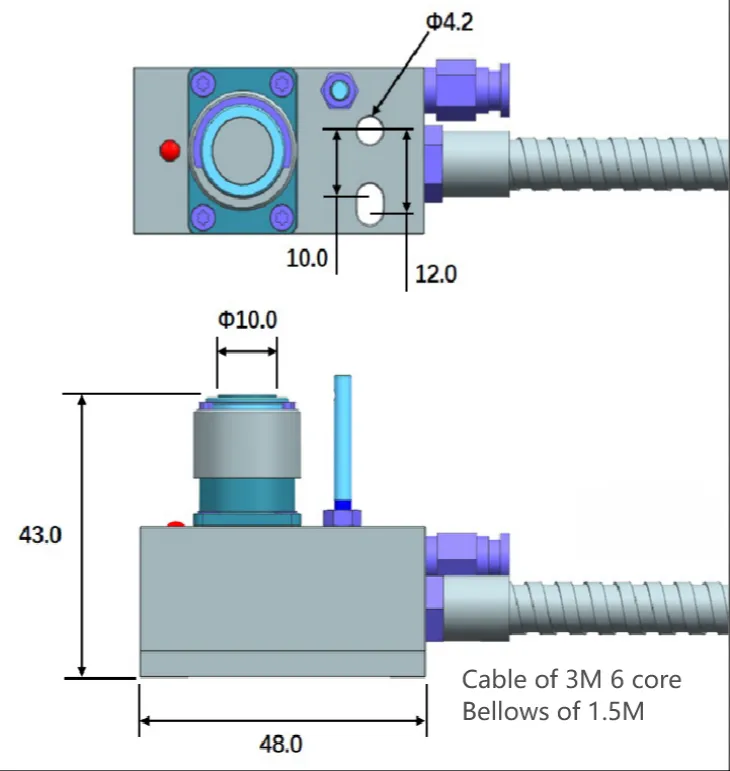

Compact design with a contact-surface diameter of 10mm

Z-axis Tool Setter

- Photoelectric Trigger

- Long Trigger Life

- High Precision

- High Security

MODEL | DTS100 |

Diameter of touch pad | Φ10 |

Trigger direction | +Z |

Output | A/NC |

Trigger Protection Distance | 5.4mm |

Repeatability(2σ) | <0.5um(speed: 50~200mm/min) |

Trigger life | >20 million times |

Signal transmission mode | Cable |

Protection sealing level | IP68 |

Trigger force | 1.5N |

Touch pad material | Tungsten carbide |

Surface treatment | Grinding4S(mirror grinding) |

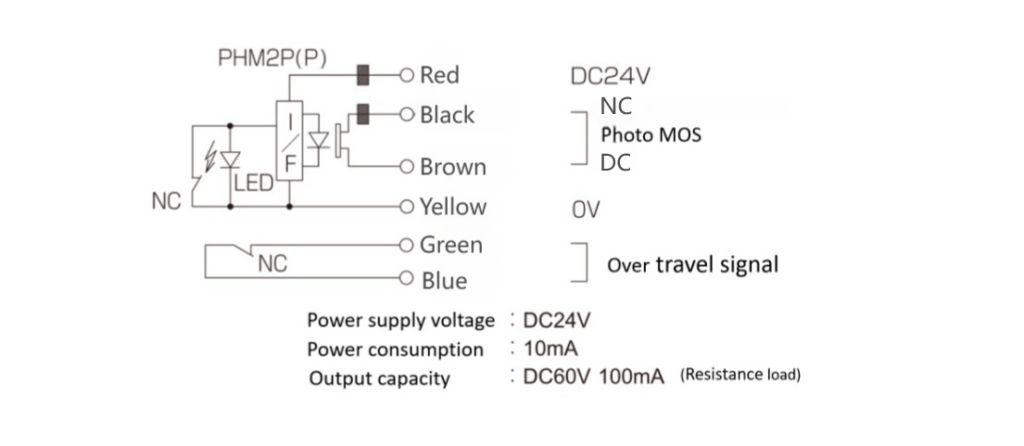

Contact nominal value | DC24V, Max20mA |

Protective tube | 1.5m, minimum radius R7mm |

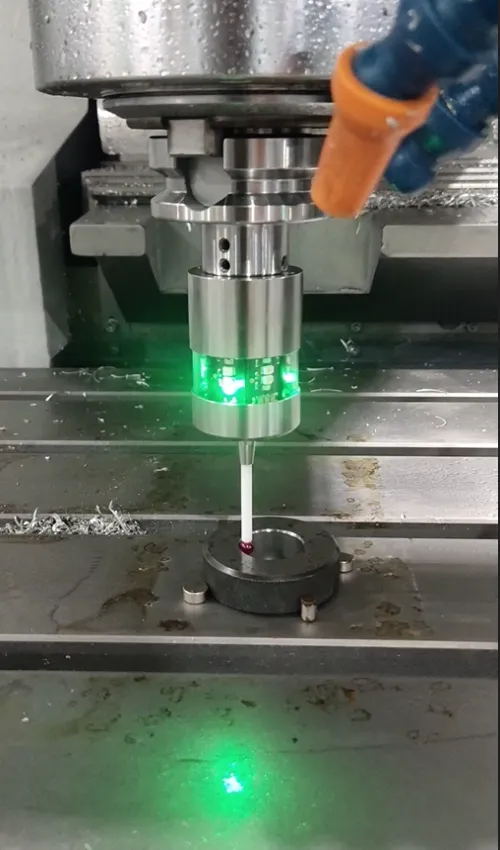

LED light | Normal: OFF; active: ON |

Features of Tool Height Setter

High Security

- Stroke 5.4mm,Longer anti-collision responsing time

- Built-in anti-collision switch, automatic anti-collision

- Visual indicator light transmits signal status

High Presicion

- Photoelectric triggering with higher sensing accuracy

- Micron-level assembly control process

- Repeat positioning accuracy (2σ) <1um

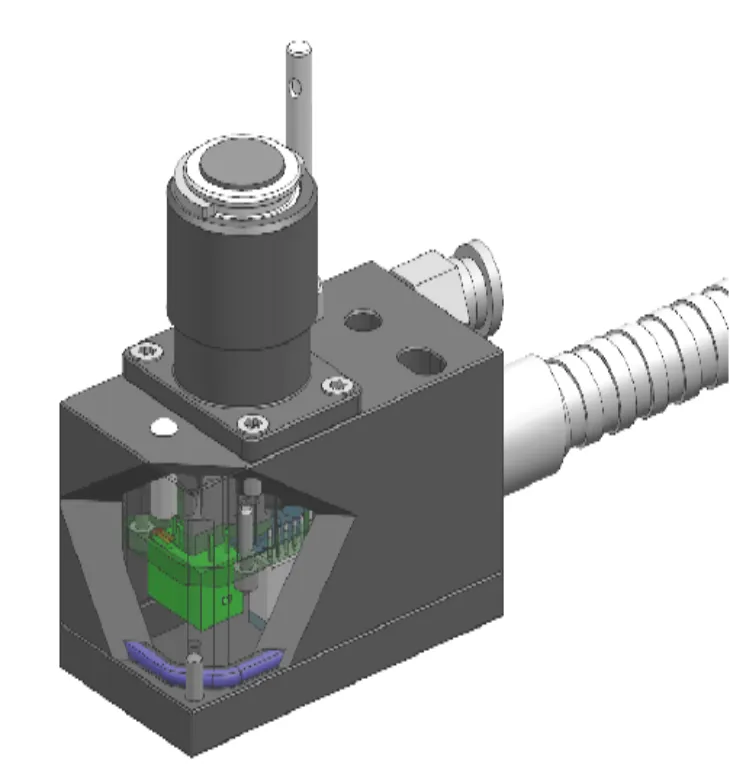

Photoelectric Trigger

- Industry-revolutionary photoelectric trigger technology

- It has unparalleled stability and trigger life advantages

Uncomparable Trigger Life

- > 10million Trigger Lifbe, which is leading in the industry

IP68 Protection Level

- Tool setter protection level is the highest IP68 rating in the industry.

Excellent Stability

- Photoelectric technology guarantees excellent stability and useful life.

Electrical Diagram of Tool Height Setter

Brief Introduction of Tool Height Setter

DTS100 is a single-axis tool height setter which is triggered when a tool touches the contact pad. A trigger signal is sent to the machine tool controller via the hard-wired cable and the tool length is automatically calculated.

This tool setter can be used for a variety of on-machine detection, such as tool length, tool breakage, tool wear compensation, and determination of tool offset. It is designed to operate within the machining environment, so it is resistant to swarf or coolant ingress and prevents false triggers due to shocks or vibration.

DTS100 is compatible with a variety of CNC processing equipment, such as drill-tapping machine, engraving and milling machine, high gloss machine, vertical machining center, horizontal machining center, five-axis machining center, gantry machining center, turn- milling complex equipment, non-standard automation equipment, etc.