Email: [email protected] Phone: (+86) 134 1323 8643

In the realm of CNC machining, precision is paramount. Achieving consistent and accurate results is crucial for producing high-quality parts. This is where CNC 3D touch probes come into play. These innovative tools act as an extension of the CNC machine’s capabilities, enabling automated workpiece setup, tool setting, and even 3D digitizing.

This article serves as a comprehensive guide to the leading brands and models of CNC 3D touch probes. We’ll delve into the functionalities of these probes, explore the key features to consider, and highlight the top contenders in the market. Additionally, we’ll introduce some emerging brands making waves in the industry. Finally, we’ll equip you with the knowledge to choose the perfect touch probe for your specific CNC application.

What Are CNC 3D Touch Probes?

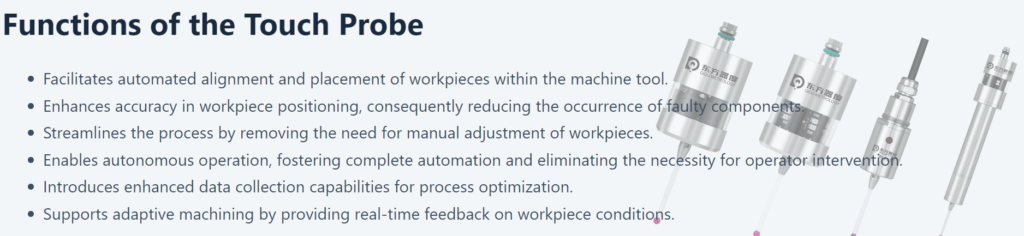

A CNC 3D touch probe is a sensor mounted on a CNC machine’s toolholder. It possesses a spring-loaded stylus that makes contact with the workpiece surface. This contact triggers a signal within the probe, relayed to the CNC control unit. This allows the machine to precisely determine the position of the workpiece on the X, Y, and Z axes in 3D space.

Key Features to Look For:

- Accuracy:Measured in microns, accuracy refers to the probe’s ability to consistently deliver precise measurements.

- Repeatability:This indicates the probe’s consistency in registering the same position upon repeated touches.

- Trigger Force:The amount of force required to activate the probe’s signal. A low trigger force minimizes workpiece deflection during measurement.

- Stylus Options:Different stylus shapes and materials cater to diverse applications. Spring-loaded styli are common, while some probes offer interchangeable tips for added versatility.

- Communication Protocol:Compatibility with your CNC machine’s control system, such as RS232 or USB.

- Durability and Build Quality:Robust construction ensures reliable performance and minimizes downtime due to malfunctions.

Benefits of Using CNC 3D Touch Probes:

- Enhanced Precision:Automates tool setting and workpiece setup, eliminating manual errors and improving machining accuracy.

- Reduced Setup Time:Streamlines the setup process, leading to increased productivity.

- Material Savings:Minimizes tool breakage and material waste by ensuring precise tool offsets.

- Improved Workpiece Quality:Consistent and accurate machining leads to parts with superior quality and dimensional stability.

- Versatility:Applicable for various tasks, including tool offset calibration, workpiece zero point setting, 3D digitizing of complex shapes, and even in-process inspection.

The Leading Brands in CNC 3D Touch Probes

1. Renishaw

Overview of Renishaw’s Reputation: Renishaw is a global leader in metrology and a pioneer in CNC touch probe technology. They are renowned for their exceptional accuracy, reliability, and innovative designs.

Popular Models:

- Renishaw RMP600:This versatile probe delivers high accuracy (up to 3 microns) and boasts a robust design for demanding machining environments.

- Renishaw OMP40-2:This compact and lightweight probe is ideal for applications requiring high precision in limited space.

Key Features and Innovations: Renishaw is known for its innovative features like advanced filtering technology that minimizes signal noise and patented kinematic designs that ensure exceptional repeatability.

2. Heidenhain

Heidenhain’s Market Presence: Another major player in the CNC industry, Heidenhain offers a comprehensive range of CNC controls and accessories, including high-quality touch probes.

Top Models:

- TS 460:This versatile probe features a compact design and robust build for various machining applications.

- TS 740:Designed for high-speed machining, the TS 740 offers excellent accuracy and a low trigger force for minimal workpiece deflection.

Distinctive Features and Advantages: Heidenhain’s probes are known for their user-friendly design, intuitive operation, and seamless integration with Heidenhain CNC controls.

3. Blum-Novotest

Blum-Novotest’s Industry Impact: Blum-Novotest is a leading manufacturer of high-precision measuring instruments for the machine tool industry. Their touch probes are renowned for their advanced technology and exceptional reliability.

Highlight Models:

- TC52:This compact probe offers high accuracy (up to 2 microns) and a robust design for various machining tasks.

- TC76:Designed for heavy-duty applications, the TC76 boasts a rugged

4. Hexagon Manufacturing Intelligence

Hexagon’s Contribution to CNC Technology: Hexagon, through its subsidiary Metrology, offers a comprehensive suite of CNC solutions, including high-performance touch probes.

Noteworthy Models:

- m&h RWP38.41:This versatile probe delivers exceptional accuracy (up to 2 microns) and features a durable design for demanding environments.

- m&h RWP20.50:Ideal for applications requiring high speed and minimal trigger force, the RWP20.50 is a popular choice for high-production machining.

Unique Selling Points and Enhancements: Hexagon’s probes are known for their advanced features like wireless communication options and software integration for improved data analysis and process control.

5. Qidu Metrology

Overview of Qidu Metrology’s CNC Technology: Qidu Metrology is a prominent Chinese manufacturer of CNC accessories, including a growing range of affordable and reliable touch probes.

Popular Models:

- DOP40:This cost-effective optical infrared touch probe offers decent accuracy (up to 1 microns) and is suitable for basic machining applications.

- DRP40:Designed for applications requiring higher accuracy (up to 1 microns), the radio touch probe DRP40 is a good mid-range option.

Distinctive Features and Advantages: Qidu Metrology caters to the budget-conscious market, offering cost-effective probes with decent performance for basic to moderate machining needs.

6. Marposs

Marposs’ Role in Precision Engineering: Marposs is a leading global provider of metrology and quality control solutions for the manufacturing industry. Their touch probes are known for their reliability and innovative features.

Key Models:

- T25:This compact and lightweight probe offers good accuracy (up to 3 microns) and is suitable for various machining applications.

- T35:Designed for demanding environments, the T35 boasts a robust build and advanced features like automatic stylus wear compensation.

Innovative Features and Reliability: Marposs prioritizes reliability and user-friendliness in their probe designs. They offer features like automatic calibration and self-diagnostics to minimize downtime and ensure consistent performance.

Emerging Brands to Watch in CNC 3D Touch Probes

The market for CNC 3D touch probes is constantly evolving, with new players entering the scene. Here are a couple of emerging brands to keep an eye on:

1. Metrol

Metrol’s Market Entry and Growth: Metrol is a relatively new brand making strides in the CNC touch probe market. Their probes offer a good balance of features and affordability.

Prominent Models:

- MP200:This entry-level probe provides basic functionality at a competitive price point.

- MP300:Offering improved accuracy and features compared to the MP200, the MP300 caters to users seeking a balance between performance and cost.

Competitive Features: Metrol focuses on offering user-friendly and reliable probes at competitive prices, making them a good option for budget-conscious users or those new to CNC touch probe technology.

2. Haff & Schneider

Introduction to Haff & Schneider: A German manufacturer known for high-quality machine tool accessories, Haff & Schneider is expanding its offerings to include CNC touch probes.

Best Models:

- Probe-20:This compact probe offers basic functionality for simple machining applications.

- Probe-30:Designed for more demanding tasks, the Probe-30 boasts improved accuracy and features compared to the Probe-20.

Strengths and Potential: Haff & Schneider leverages its reputation for quality to offer reliable touch probe solutions. As they establish themselves further in the market, we can expect them to introduce more advanced models with additional features.

Comparing the Top CNC 3D Touch Probe Models

Choosing the right CNC 3D touch probe requires careful consideration of your specific needs and budget. Here’s a breakdown of some key factors to compare different models:

A. Precision and Accuracy

- Accuracy:Look for probes with accuracy specifications that meet or exceed your required tolerances.

- Repeatability:Ensure the probe consistently registers the same position upon repeated touches.

Impact on Machining Quality: High precision and repeatability are crucial for achieving consistent and accurate machining results.

B. Durability and Reliability

- Material and Build Quality:Opt for probes constructed with robust materials and a well-sealed design to withstand harsh machining environments.

- Longevity and Maintenance Requirements:Consider the probe’s expected lifespan and ease of maintenance.

**Reliable probes minimize downtime due to malfunctions and ensure consistent performance over time.

C. Ease of Use and Integration

- User-Friendly Features:Look for probes with intuitive controls, clear status indicators, and readily available user manuals.

- Compatibility with Various CNC Machines:Ensure the probe’s communication protocol (e.g., RS232, USB) is compatible with your CNC machine’s control system.

**Easy-to-use probes minimize setup time and operator training requirements, while seamless integration ensures smooth operation with your existing CNC machine.

D. Price vs. Performance

- Cost Analysis of Leading Models:Consider the upfront cost of the probe alongside its features, accuracy, and expected lifespan.

- Value for Money Considerations:Look for a probe that offers the best balance of performance and affordability to meet your specific needs.

**While high-end probes offer superior accuracy and features, budget-friendly options can be suitable for basic machining applications. Finding the right balance between price and performance is key.

How to Choose the Right CNC 3D Touch Probe for Your Needs

With a good understanding of the leading brands, models, and key considerations, you’re well-equipped to choose the right CNC 3D touch probe for your application. Here are some additional tips:

Assessing Your Specific Requirements:

- Machining Applications:Consider the types of parts you machine, the required tolerances, and the materials you work with.

- Machine Compatibility:Ensure the probe is compatible with your CNC machine’s control system and available mounting options.

- Budget Constraints:Determine your budget and prioritize features based on their importance to your specific needs.

Tips for Making an Informed Decision:

- Research and Compare Models:Utilize online resources and manufacturer specifications to compare different probes.

- Consult with Industry Experts:Seek advice from experienced machinists or distributors who can recommend suitable probes for your application.

- Consider Future Needs:If you anticipate expanding your machining capabilities, choose a probe with features that can accommodate future growth.

Where to Buy and What to Look Out For:

- Reputable Distributors:Purchase your touch probe from a reliable distributor who offers technical support and after-sales service.

- Warranty and Support:Ensure the probe comes with a warranty and that the distributor offers technical support in case of any issues.

- Calibration Services:Consider the availability of calibration services to maintain the probe’s accuracy over time.

People Also Ask About CNC 3D Touch Probes

Here are some frequently asked questions about CNC 3D touch probes:

1. What are the main benefits of using CNC 3D touch probes?

The main benefits include:

- Enhanced precision and reduced errors in tool setting and workpiece setup.

- Increased productivity due to faster setup times.

- Reduced material waste by minimizing tool breakage and ensuring accurate machining.

- Improved workpiece quality through consistent and precise machining.

- Versatility for various tasks, including in-process inspection and 3D digitizing.

2. How do I maintain and calibrate a CNC 3D touch probe?

Refer to the manufacturer’s instructions for specific maintenance procedures. Generally, this may involve keeping the probe clean, inspecting for stylus wear, and following recommended calibration intervals.

3. Can CNC 3D touch probes be used with any CNC machine?

No, compatibility is crucial. Ensure the probe’s communication protocol matches your CNC machine’s control system.

4. What factors should I consider when choosing a CNC 3D touch probe?

Consider accuracy, repeatability, durability, ease of use, compatibility with your CNC machine, and budget constraints.

5. Are there any common issues with CNC 3D touch probes, and how can they be resolved?

Potential issues include stylus wear, signal noise, and communication errors. Regular maintenance, proper calibration, and consulting the manufacturer’s troubleshooting guides can help resolve these issues.

Conclusion

CNC 3D touch probes are powerful tools that significantly enhance the capabilities of CNC machining. By understanding the leading brands, models, and key selection factors, you can make an informed decision and invest in a probe that optimizes your machining processes, improves production efficiency, and ultimately elevates the quality of your finished parts.

Remember, opting for a high-quality CNC 3D touch probe is an investment that pays off in the long run by minimizing errors, reducing costs, and ensuring consistent precision in your CNC machining operations.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.