Email: [email protected] Phone: (+86) 134 1323 8643

Abstract: This article delves into the current state of the wholesale touch probe sensor field, including its significance, working principles, application areas, advantages of wholesale procurement, considerations when selecting suppliers, and a comparative analysis of industry-leading manufacturers.

I. Introduction

Wholesale Touch probe sensors are precision instruments used to measure the dimensions, shape, and position of objects. They find extensive applications in industries, healthcare, research, and more. With technological advancements, touch probing sensor performance and functionality continue to improve, making them an increasingly popular choice among users.

II. Understanding Wholesale Touch Probe Sensors

The working principle of wholesale touch probe sensors involves using electrical, optical, or magnetic principles to detect the presence or position of objects. Common types of touch probing sensors include:

- Capacitive touch probing sensors: Detect the presence of objects by changes in the electric field.

- Optical touch probing sensors: Use optical signals to detect the presence or position of objects.

- Magnetic touch probing sensors: Utilize changes in the magnetic field to detect the presence or position of objects.

Touch probing sensors are applied in various fields, including:

- Manufacturing and Machining:

CNC Machining: Touch probes are commonly used in computer numerical control (CNC) machining to measure workpiece dimensions, check tool offsets, and verify part geometries during the manufacturing process.

Quality Control: These sensors help ensure the accuracy and quality of machined parts by performing in-process inspections and verifying dimensional accuracy.

- 3D Metrology:

Coordinate Measuring Machines (CMM): Touch probes are integral components of CMMs, used for measuring the dimensions and positions of objects in three-dimensional space. They contribute to precise and automated inspection processes in industries like aerospace and automotive.

- Automotive Industry:

Quality Assurance: Touch probing sensors are employed for quality control in automotive manufacturing to inspect critical components, ensuring that they meet design specifications.

Assembly Line: They help in aligning and positioning parts during assembly processes, contributing to efficient and accurate production.

- Aerospace Industry:

Machining and Inspection: Touch probes assist in the manufacturing of aerospace components by ensuring tight tolerances and verifying the integrity of critical parts.

Maintenance and Repair: Used for inspecting and measuring components during maintenance and repair operations.

- Medical Device Manufacturing:

Precision Machining: Touch probes are utilized to measure and inspect small, intricate components in the production of medical devices, ensuring high quality and compliance with standards.

- Electronics Manufacturing:

PCB Inspection: Touch probing sensors help in the inspection of printed circuit boards (PCBs), ensuring the accuracy of soldered components and the overall quality of electronic assemblies.

- Tool and Die Making:

Tool Inspection: Touch probes are used to inspect and measure the dimensions of cutting tools and dies, ensuring their accuracy and longevity.

- Research and Development:

Prototype Development: Touch probing sensors play a role in the development and testing of prototypes, helping engineers and researchers validate designs and measure critical parameters.

- Art and Sculpture Conservation:

Artifact Measurement: In conservation efforts, touch probes are used to measure and document the dimensions of artifacts, sculptures, and other cultural heritage items.

- Dental Prosthetics Manufacturing:

Customization: Touch probes assist in the precise measurement and customization of dental prosthetics, ensuring a perfect fit for individual patients.

III. Advantages of Wholesale Procurement

Wholesale procurement of touch probe sensor offers the following advantages:

- Lower prices: Wholesale distributors typically provide more favorable pricing.

- Greater selection: Wholesale distributors usually offer a more comprehensive product line to meet diverse user needs.

- Convenient services: Wholesale distributors often offer professional technical support and after-sales services.

When choosing the right touch probe sensor manufacturer or supplier, consider the following factors:

- Product quality and performance: Choose reliable manufacturers or suppliers to ensure products meet required standards.

- Product pricing: Compare prices to select products with the best value for money.

- Supplier services: Select suppliers capable of providing comprehensive technical support and after-sales services.

IV. Industry-Leading Manufacturers of Wholesale Touch Probe Sensor

The following are leading manufacturers in the wholesale touch probe sensor industry:

- Renishaw: A UK company providing high-precision touch probing sensors and measurement systems.

- Haimer: A German company offering various types of touch probing sensors and accessories.

- Blum: An Austrian company providing touch probing sensors and measurement systems for machine tools.

- Mitutoyo: A Japanese company offering various precision measuring instruments, including touch probing sensors.

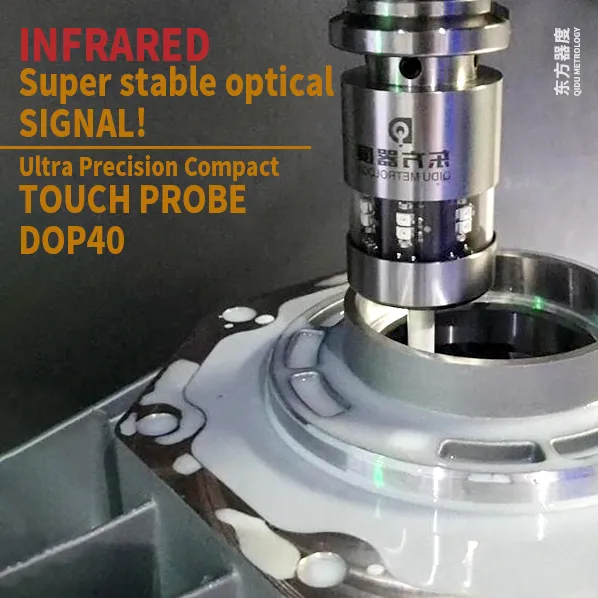

- Qidu Metrology: A Chinesecompany providing optical and radio touch probing sensors.

V. Frequently Asked Questions

What is the price range of touch probe sensors?

The price of touch probe sensors depends on factors such as type, accuracy, functionality, and brand. Generally, prices range from hundreds to tens of thousands of USD.

How to install touch probe sensors?

The installation method of touch probe sensors depends on their type and application scenario. Typically, sensors need to be installed in suitable positions and connected to the corresponding measuring instruments or control systems.

How to maintain touch probe sensors?

To ensure the normal operation of touch probe sensors, regular maintenance is required, including cleaning, calibration, and inspection.

VI. Conclusion

Touch probing sensors are crucial measurement tools playing significant roles in various fields. Wholesale procurement can help users obtain higher quality products and services at lower prices. This article has introduced the current state of wholesale touch probing sensors, aiming to assist users in better understanding and selecting these sensors.

Katrina

Mechanical Sales Engineer with 10+ years of experience in the manufacturing industry.Skilled in developing and executing sales strategies, building relationships with customers, and closing deals. Proficient in a variety of sales and marketing tools, including CRM software, lead generation tools, and social media. I'm able to work independently and as part of a team to meet sales goals and objectives. Dedicated to continuous improvement and learning new sales techniques.